The impact of zirconium silicate on ceramic tile production is a topic of increasing importance in the ceramics industry. As manufacturers seek to meet ever-growing consumer demands, they face the challenge of producing tiles that are not only aesthetically pleasing but also durable and cost-effective. This article will address that problem comprehensively by exploring how this unique material improves tile properties and overall manufacturing processes. With years of industry experience and research backing up its benefits, insights will be shared to help decision-makers understand both the advantages and challenges of integrating zirconium silicate into their production lines. This information is crucial for those in strategic positions aiming to enhance their offerings while securing customer satisfaction.

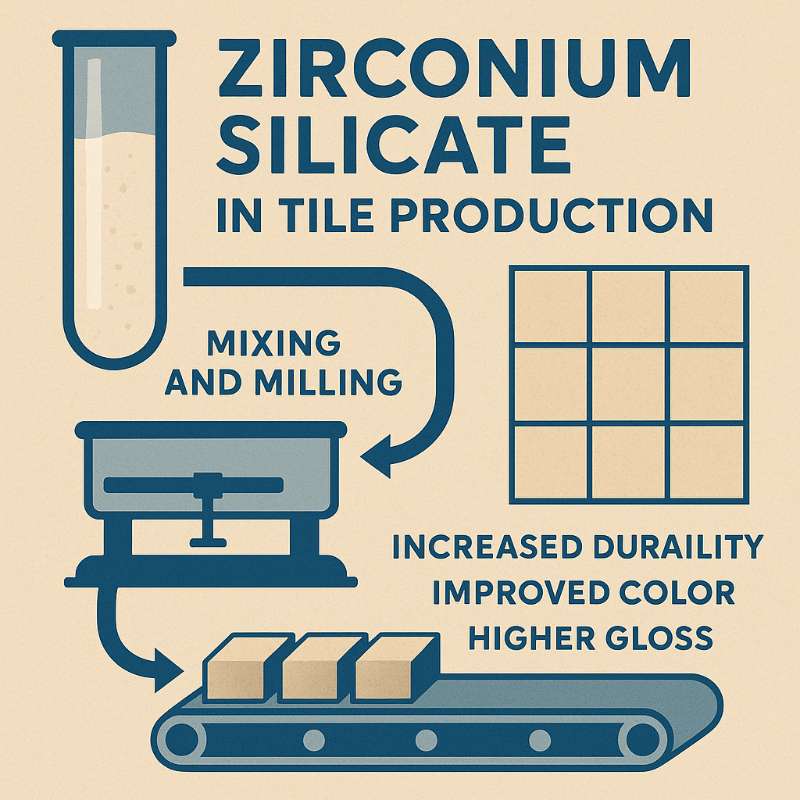

This image illustrates the use of zirconium silicate to enhance tile quality.

How Does Zirconium Silicate Enhance Ceramic Tiles?

The role of zirconium silicate in enhancing the quality of ceramic tiles is multi-faceted and critically important. As an additive, it significantly improves both the physical and aesthetic properties of the ceramic body and the surface glaze, making it an indispensable component for modern tile production.

One of the most notable advantages is the increased strength and durability of tiles. Zirconium silicate improves the structural integrity of tiles, helping them withstand various physical stresses. This durability is especially important in settings subject to heavy foot traffic, such as retail spaces, kitchens, and bathrooms, where tiles often encounter potential impacts. Manufacturers can minimize the likelihood of breakage and ensure that tiles endure the rigors of daily use, resulting in a longer-lasting product that remains reliable over time.

In addition to durability, zirconium silicate enhances the aesthetic aspects of tiles. It contributes to a finer surface finish, leading to a brighter and more appealing final product. The smooth texture and lustrous sheen enabled by the addition of zirconium silicate increase the visual allure of tiles, making them more attractive to potential buyers. Aesthetic appeal plays a significant role in consumer choice, particularly in markets where design trends continuously evolve. Hence, providing tiles that not only perform well but also look good can set manufacturers apart in an increasingly competitive market.

Here’s the deal: Incorporating this additive into ceramic tiles allows for the development of more robust products that can handle the demands of everyday life. Improved resistance to wear and tear means that tiles can last significantly longer than their counterparts without this material. Consequently, this innovation can reduce customer complaints and lower warranty costs for manufacturers. Such improvements not only enhance brand loyalty but can also provide a competitive edge in a crowded market, reinforcing the manufacturer’s position as a provider of high-quality and reliable products. By investing in zirconium silicate, manufacturers not only ensure customer satisfaction but also position themselves favorably for future growth and market expansion.

What are the Key Properties of Zirconium Silicate?

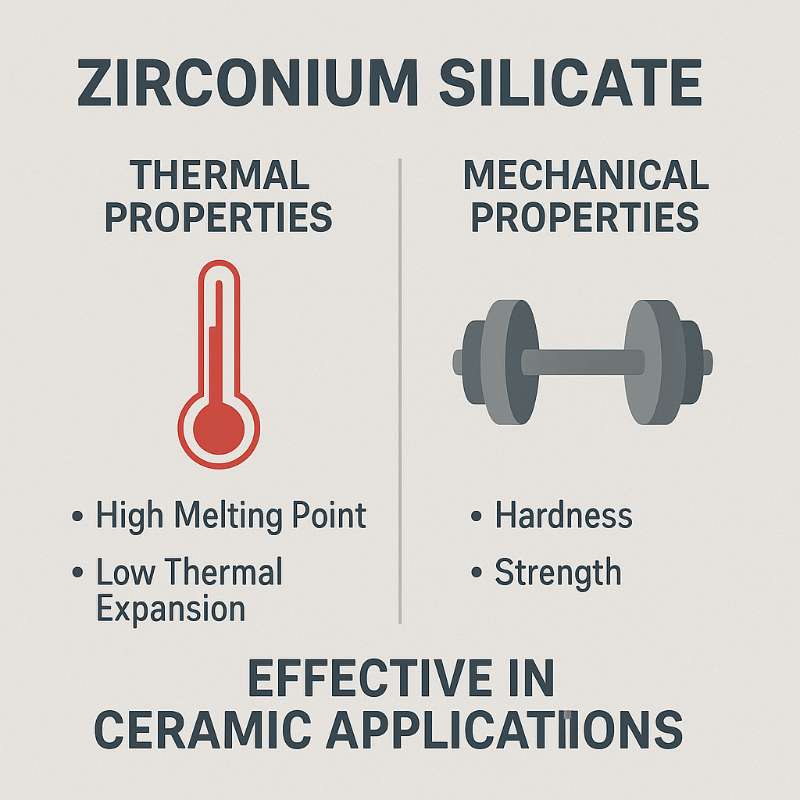

Understanding the key properties of zirconium silicate is essential for recognizing its effectiveness as a ceramic additive. The material boasts significant physical properties that contribute remarkably to tile manufacturing. It is chemically stable, which offers consistent performance across varying conditions. This stability translates to reliable production processes, where manufacturers can expect the same results batch after batch, making it easier to maintain quality standards.

Moreover, zirconium silicate exhibits strong thermal properties. It has a high melting point, which allows for greater flexibility during the firing process of tiles. This quality is particularly beneficial for manufacturers aiming to produce larger or more intricate designs. The ability to withstand higher temperatures means that manufacturers can push the boundaries of design and innovation without fear of material failure.

You might be wondering: why do these properties matter? They ensure that the end product will maintain its integrity through temperature fluctuations and stresses encountered during everyday usage and installation. Thus, incorporating this material can enhance overall customer satisfaction and minimize logistical issues due to defective products, thereby saving costs for manufacturers.

Visual representation of the thermal and mechanical properties of zirconium silicate, demonstrating its effectiveness in ceramic applications.

How Does Zirconium Silicate Influence Manufacturing Processes?

The integration of zirconium silicate in ceramic tile production profoundly influences various manufacturing processes. Its role begins during the initial mixing phase of raw materials. The incorporation of this additive can modify how other ingredients interact, often improving the homogeneity of the mixture. A well-mixed formulation leads to a more uniform product, reducing defects and ensuring consistency in tile quality.

During the firing process, zirconium silicate helps regulate temperature and promote even heating throughout the batch. Even heating is crucial as it leads to fewer defects, such as warping or unevenly glazed surfaces. In high-volume production settings, a reduction in defects directly translates to better efficiency and reduced material waste, thereby improving the overall profitability of the manufacturing process.

What’s more, using this material can streamline the application of glazes. It enhances glaze adhesion and finish quality, which are vital for aesthetic aspects that consumers prioritize. A better finish not only appeals to customers but can also reduce the need for costly touch-ups, further enhancing the bottom line. By addressing these elements effectively, manufacturers can meet both performance standards and consumer expectations more efficiently.

| Property | Benefit |

|---|---|

| High Strength | Reduced breakage rates |

| Thermal Stability | Consistent firing results |

| Improved Finish | Aesthetic appeal |

What Are the Advantages of Using Zirconium Silicate?

Zirconium silicate presents a plethora of advantages for manufacturers in the ceramic tile industry. Firstly, it significantly strengthens tiles, making them resilient to cracking and chipping. This durability prolongs the life of the tiles, which not only enhances performance but also improves customer satisfaction. Clients are more likely to choose products known for their longevity and reliability.

Secondly, its role in enhancing the surface finish cannot be overstated. Tiles that incorporate this material often exhibit a smoother and glossier appearance. This aesthetic benefit can have a considerable influence on consumer choice, especially in decorative applications where visual appeal is paramount. Builders and homeowners alike prioritize tiles that not only perform well but also look attractive in their spaces.

Furthermore, zirconium silicate is cost-effective in the long run. While it may incur higher upfront costs in comparison to other additives, the long-term savings derived from reduced defects and warranty claims can lead to significantly enhanced profit margins for manufacturers. This balance between quality and expense is critical for decision-makers looking to streamline their operations while providing top-notch products.

| Benefit | Description |

|---|---|

| Increased Durability | Longer product lifespan |

| Enhanced Aesthetics | Improved surface finish |

| Cost Efficiency | Reduced warranty claims |

What Challenges Might Arise with Zirconium Silicate Use?

While there are many benefits to incorporating zirconium silicate, manufacturers should also consider potential challenges that arise from its use. Handling this material can be tricky; it is often a fine powder that may create dust issues in production environments. This necessitates proper ventilation and protective measures to ensure safety and compliance with health regulations.

Another major concern involves the environmental impact associated with zirconium silicate. Like many industrial materials, its disposal must adhere to specific regulations. Improper handling can lead to environmental harm, and manufacturers must be diligent in complying with all applicable guidelines to ensure sustainable operations.

Compatibility with other materials is yet another issue manufacturers may face. Some raw materials may not blend well with zirconium silicate, leading to defects in the final product. Continuous testing and modification of formulations may be required to achieve the desired results without compromising quality.

Remember that proactively addressing these concerns will create a smoother production process and safeguard the brand’s reputation. Being prepared for these challenges can also enhance a manufacturer’s credibility in the eyes of clients who prioritize environmentally responsible practices.

How Does Zirconium Silicate Compare to Other Additives?

When comparing zirconium silicate to other common additives such as quartz and feldspar, the differences in performance become apparent. Each material offers unique benefits that can contribute to the tile-making process; however, zirconium silicate stands out in terms of strength and thermal stability.

For instance, while feldspar is recognized for its excellent fluxing properties, it does not provide the same level of durability that zirconium silicate brings to the table. Conversely, quartz may enhance the hardness of tiles, but it can compromise the surface finish compared to formulations with zirconium silicate.

Here’s a brief comparison:

| Material | Benefits | Limitations |

|---|---|---|

| Zirconium Silicate | High strength and aesthetic appeal | Dust handling and compatibility issues |

| Feldspar | Good fluxing agent | Weaker durability |

| Quartz | Improves hardness | May affect glaze smoothness |

By evaluating these materials, manufacturers can choose the most suitable options for specific applications, enhancing their product offerings and satisfying diverse consumer needs.

What Are the Real-World Applications of Zirconium Silicate?

Zirconium silicate finds a broad spectrum of applications within the ceramics industry. One of its primary uses is in the production of wall and floor tiles. Thanks to its superior durability and aesthetic enhancements, it has become a popular choice among manufacturers aiming for high-quality results that can withstand daily use.

Moreover, this material is employed in specialty tiles, designed specifically for high-traffic areas. Such environments, often found in commercial settings, require products that can handle increased use without succumbing to wear and tear. The resilience offered through the integration of zirconium silicate ensures that tiles remain visually appealing and functionally intact.

Let’s look at a case study: A leading manufacturer introduced zirconium silicate into their product line and reported a remarkable 20% reduction in breakage incurred during shipping. This not only saved costs but also led to increased customer trust and improved feedback, ultimately translating into higher sales figures. Such outcomes demonstrate the tangible benefits of this material in real-world scenarios.

This image shows various practical applications of tiles incorporating zirconium silicate, highlighting their durability and aesthetics.

How Can Manufacturers Optimize Zirconium Silicate Use?

To derive maximum benefit from zirconium silicate, manufacturers should adopt best practices for its integration into their operations. First and foremost, thorough testing during the formulation phase is critical. This ensures that optimal ratios are determined, enhancing the material’s performance without compromising cost-effectiveness.

Investing in staff training is also advantageous. By educating employees on the properties and handling requirements, manufacturers can improve both safety and efficiency in their production lines. Enhanced understanding of the material allows teams to anticipate and mitigate challenges before they escalate.

Here’s the bottom line: Implementing innovative practices and maintaining an adaptable mindset will help manufacturers fully leverage the advantages associated with this additive, ultimately enhancing productivity and ensuring higher quality in output.

| Optimization Strategy | Description |

|---|---|

| Testing Ratios | Determine optimal ingredient levels |

| Staff Training | Improve safety and efficiency |

| Continuous Improvement | Adapt to new findings for better outcomes |

What Do Industry Experts Say About Zirconium Silicate?

Industry experts consistently emphasize the significance of zirconium silicate in modern ceramics manufacturing. Insights shared by leading professionals indicate that its benefits often outweigh typical challenges when managed and utilized correctly. As a result, companies are encouraged to stay informed on ongoing research to further innovate in material applications.

In interviews with various manufacturers, many reported increased market competitiveness when they implemented zirconium silicate into their product lines. As businesses strive to meet rapidly evolving customer demands, this material has proven to be a consistently beneficial component in product development.

The takeaway is clear: Investing in the latest findings regarding zirconium silicate can provide a strategic advantage. Keeping abreast of new research allows businesses to stay on the cutting edge, solidifying their status as leaders in the ceramics market.

How Will Zirconium Silicate Impact Future Tile Developments?

Looking towards the future, zirconium silicate is set to play an increasingly significant role in tile developments. As manufacturers seek ways to improve sustainability and enhance product performance, the advantages provided by this unique material warrant further exploration.

Emerging technologies in tile production may leverage zirconium silicate to enhance overall efficiency while reducing waste. New sustainable manufacturing practices will likely gain traction, and the durability of zirconium silicate can simplify compliance with stricter regulations.

What does this mean for manufacturers? By aligning with future trends and innovations, they can position themselves as forward-thinking leaders in an evolving market. Consequently, this ensures that zirconium silicate remains a critical component in their production strategy.

Conclusion

In conclusion, the incorporation of zirconium silicate into ceramic tile production offers substantial advantages that can significantly enhance the overall quality and performance of tiles. By adding strength and durability to the products, improving aesthetics, and reducing warranty claims, this additive makes a compelling case for adoption in manufacturing processes. Moreover, the ability to maintain high standards of quality allows manufacturers to build a strong reputation and foster customer loyalty in a competitive market.

Global Industry encourages manufacturers to thoroughly evaluate their production operations and seriously consider integrating this innovative material for improved outcomes and efficiency. By doing so, they can not only meet increasing consumer demands but also align with sustainability goals that are becoming essential in today’s manufacturing landscape. For further insights into optimizing production lines and exploring additional innovative solutions, connect with us for tailored recommendations and expert advice that aligns with your specific business needs. Together, we can drive the future of ceramics manufacturing while ensuring quality and customer satisfaction.

FAQ Section

Q1: What is zirconium silicate used for in ceramics?

Zirconium silicate is primarily utilized in ceramic tile manufacturing as an additive to improve the strength, durability, and surface quality of the tiles. Its chemical stability and thermal properties make it an essential ingredient for enhancing the overall performance of ceramic products, allowing them to withstand wear and tear while maintaining an attractive finish.

Q2: Are there environmental concerns with zirconium silicate?

Yes, handling and disposal of zirconium silicate must be managed carefully to minimize any potential environmental impact. While the material itself is relatively stable, improper disposal can lead to environmental pollution. Manufacturers should adhere to relevant regulations and implement safe handling practices to ensure that they are not contributing to harmful ecological effects.

Q3: How does zirconium silicate enhance tile properties?

Zirconium silicate significantly enhances various properties of ceramic tiles, including mechanical strength, thermal stability, and aesthetic appeal. Its integration into tile production results in products that are less prone to cracking and chipping, can endure temperature fluctuations better, and exhibit a smoother, more glossy finish that appeals to consumers.

Q4: What is the cost-effectiveness of using zirconium silicate?

While the initial procurement costs for zirconium silicate may be higher compared to other additives, the long-term savings can be substantial. The improved durability and decreased defect rates lead to fewer warranty claims and replacement costs. Moreover, better-performing products can command higher prices in the market, ultimately resulting in increased profit margins for manufacturers.

Q5: What are the future trends for zirconium silicate in manufacturing?

Future trends suggest that zirconium silicate will play an increasingly important role in sustainable production practices. As manufacturers seek to improve efficiency and reduce waste, the properties of zirconium silicate may enable them to create innovative ceramic products that meet stricter environmental standards. Additionally, ongoing research may uncover new applications for this versatile material in various ceramic products, further solidifying its importance in the industry.