Battery performance remains a critical concern for many industries, especially as the demand for efficient energy solutions grows globally. Businesses are increasingly seeking innovative ways to enhance the longevity and efficiency of their battery systems. Among the materials gaining attention, zirconium silicate has emerged as a promising solution. This compound not only provides enhancements in battery performance, but it also plays a key role in ensuring that batteries operate reliably across different applications.

Understanding the specific benefits of integrating this material can give businesses a significant edge in adopting advanced energy solutions. In this article, we will explore the multifaceted advantages offered by zirconium silicate in battery applications, providing thorough insights that will help decision-makers determine the best materials for their energy storage needs.

How Does Zirconium Silicate Enhance Battery Performance?

Zirconium silicate plays a vital role in the performance of batteries, particularly in improving their overall efficiency and effectiveness. At its core, this material optimizes the ion transport mechanisms within batteries, which is crucial for enhancing energy storage capabilities. By optimizing these pathways, batteries can achieve faster charging times and improved energy density. Let’s break this down: when this particular compound is integrated into a battery design, it allows for a more effective conduction of ions, resulting in batteries that can store and release energy much more efficiently.

One of the key benefits of using this compound is its ability to reinforce the structural integrity of battery components. For instance, many batteries face issues related to thermal degradation over extended use. The inclusion of zirconium silicate helps mitigate this issue significantly. Its thermal protective properties minimize risks associated with overheating, which could otherwise lead to battery failure, reduced efficiency, or safety hazards.

Additionally, using this material can lead to reduced maintenance costs associated with battery operations. This reduction not only comes from enhanced durability and efficiency but also from improved battery lifespan. Battery replacements can be costly and disruptive; therefore, a longer-lasting product translates directly to savings.

Importantly, companies looking to differentiate themselves in a competitive market recognize that the cost of downtime due to battery failures can be substantial. Therefore, investing in materials that enhance performance is a prudent decision.

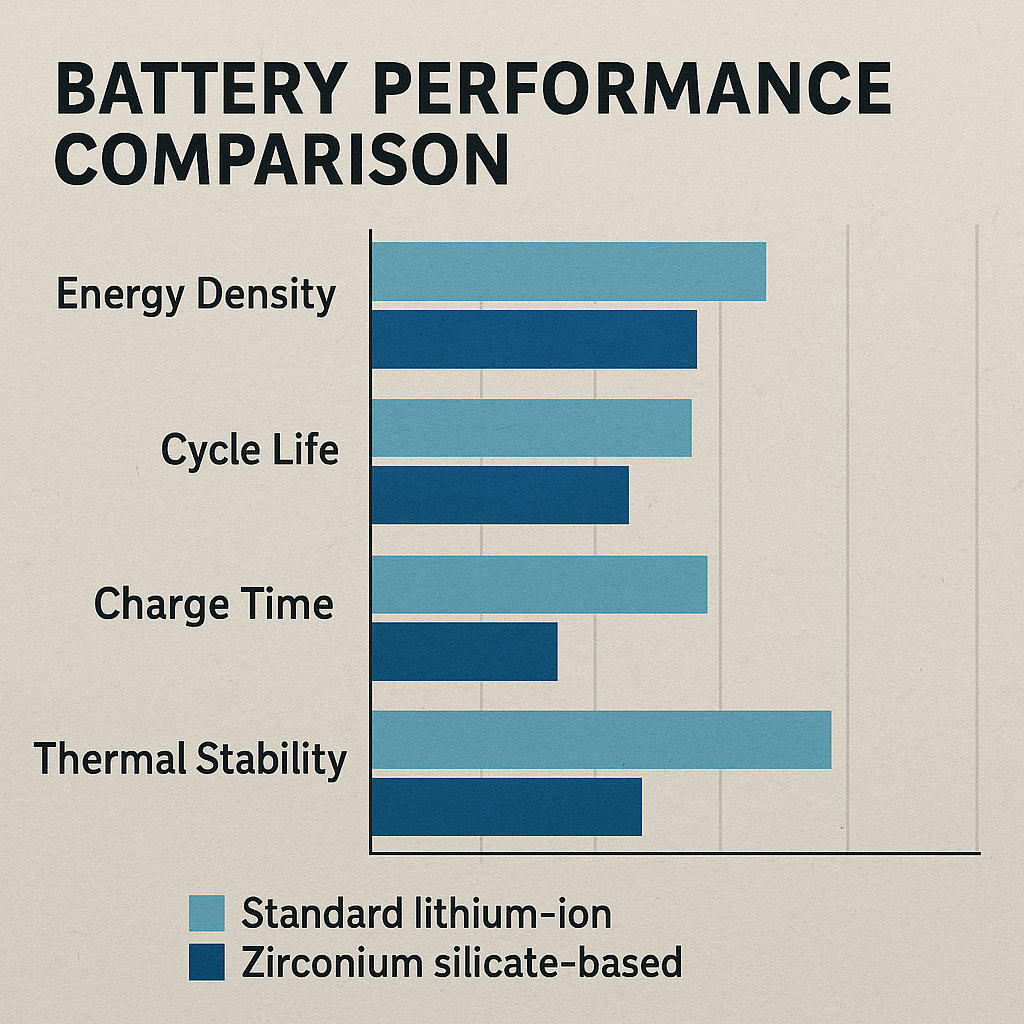

The benefits of this compound can be summarized effectively in the following table:

| Benefit | Description |

|---|---|

| Improved Ion Conductivity | Enhances charge and discharge rates, leading to faster performance. |

| Increased Thermal Stability | Reduces risks of overheating, thereby enhancing overall reliability. |

| Longer Battery Lifespan | Extending service life minimizes replacement needs. |

| Lower Maintenance Costs | Decreases costs related to replacements and repairs, improving ROI. |

This image illustrates a comparison of battery performance metrics, emphasizing the benefits provided by zirconium silicate.

What Are the Mechanisms of Zirconium Silicate in Batteries?

The functioning of zirconium silicate in batteries involves several mechanisms that significantly contribute to their performance enhancement. Understanding these fundamental mechanisms allows stakeholders to better tailor applications and designs for various battery technologies.

One key aspect is the material’s chemical interaction within the battery’s electrolyte. This interaction is crucial for facilitating proper ion movement between electrodes. The ability of this compound to harmonize with other materials in the battery ensures efficient energy conversion, which is vital for applications requiring rapid power delivery.

In addition to improving ion movement, this compound also enhances thermal stability, which is becoming increasingly vital in today’s high-performance applications. As batteries discharge energy, they can generate significant heat, particularly under heavy load conditions. If this heat is not effectively managed, it can lead to component failure or reduced capacity. The incorporation of zirconium silicate provides a buffering effect against heat, helping to absorb and redistribute thermal energy without compromising the battery’s integrity.

Furthermore, research has shown that this material increases ionic conductivity, which plays a direct role in charge and discharge cycles. This property enhances the overall efficiency of batteries, allowing industries to benefit from quicker energy turnaround times.

To summarize the mechanisms and their impacts, consider the following table:

| Mechanism | Impact |

|---|---|

| Ionic Conductivity | Enhances efficiency of charge transfer, translating to better performance in practical applications. |

| Thermal Stability | Prevents overheating and potential failures, contributing to safety and reliability. |

| Chemical Stability | Ensures consistent performance across multiple discharge cycles, extending battery life and effectiveness. |

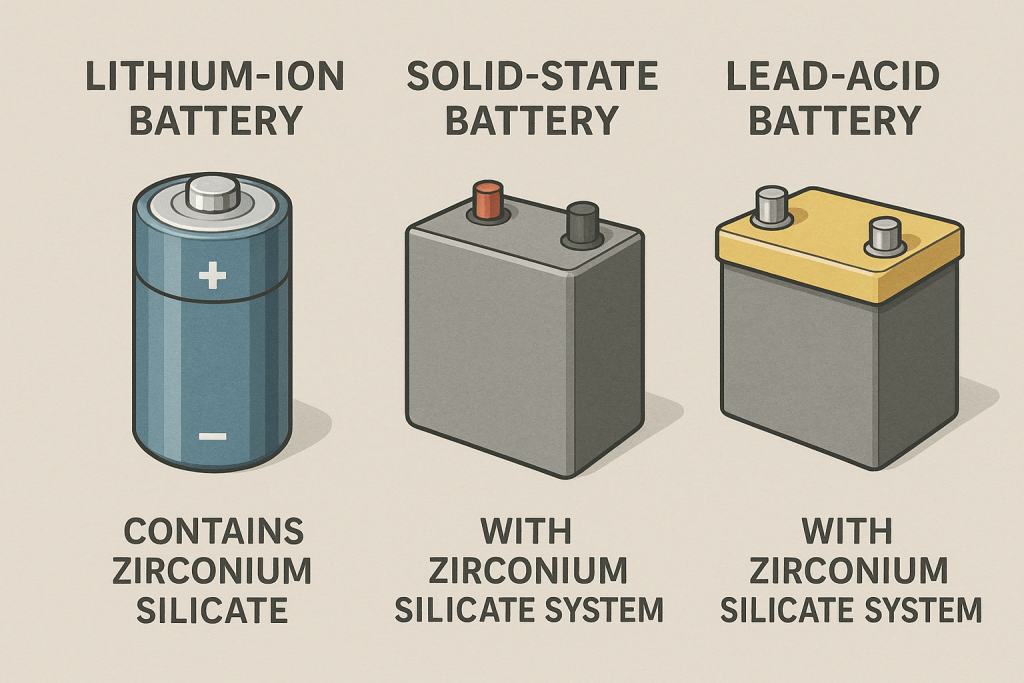

How Do Different Battery Types Benefit from Zirconium Silicate?

The versatility of zirconium silicate allows it to enhance performance across a wide variety of battery types. This adaptability is a significant advantage for manufacturers aiming to serve diverse sectors.

For example, in lithium-ion batteries, the integration of this compound results in improved cycling stability and energy density. These traits make lithium-ion batteries ideal for high-demand applications such as electric vehicles, smartphones, and laptops, where performance and reliability are paramount.

Solid-state batteries, which are seen as a promising alternative to traditional batteries, also benefit greatly from the inclusion of zirconium silicate. This material improves the performance of solid electrolytes, allowing for more efficient ionic movement. As the industry moves towards developing safer and more efficient energy storage systems, this compound becomes integral in achieving those goals.

Moreover, older battery technologies like lead-acid batteries have not been entirely phased out and still find enhancements through the incorporation of zirconium silicate. The improved discharge rates can breathe new life into these systems, making them more competitive and relevant even in modern applications.

Here is a brief overview of how various battery types benefit from this material:

| Battery Type | Benefits |

|---|---|

| Lithium-ion | Improved energy density and cycling stability. |

| Solid-state | Optimized ionic movement and enhanced voltage performance. |

| Lead-acid | Enhanced discharge rates and overall efficiency. |

This visual representation shows various types of batteries, including lithium-ion, solid-state, and lead-acid, highlighting their connection to zirconium silicate.

What Are the Current Trends in Zirconium Silicate Research?

Research into the applications and benefits of zirconium silicate is evolving rapidly, leading to numerous insights and potential future applications. Presently, studies continue to shed light on how to improve the integration of this material into existing battery technologies, focusing on achieving higher yields and efficiency.

Recently, one of the key trends involves increasing the sustainability of this material. Researchers are investigating methods to minimize environmental impacts associated with its mining and processing. By adopting eco-friendly practices, companies can better align themselves with global sustainability goals, enhancing their brand reputation.

Another significant research area is the exploration of zirconium silicate in next-generation battery technologies. With the increasing demand for alternatives to lithium-ion batteries, researchers are investigating its application in sodium-ion batteries and others. These new technologies hold a lot of promise for wider energy solutions.

The latest trends in research can be summarized in the following table:

| Trend | Description |

|---|---|

| Sustainable Sourcing | Focus on environmentally friendly extraction methods to minimize ecological disruption. |

| New Formulations | Development of advanced types of the material to enhance performance further. |

| Next-Gen Batteries | Research on innovative technologies and alternative systems that leverage this compound’s properties. |

How Does the Cost of Zirconium Silicate Affect Battery Manufacturing?

When analyzing battery manufacturing, cost considerations are paramount. The expense of zirconium silicate can considerably influence overall production costs, a crucial factor for companies evaluating their investments in battery technologies.

Although the initial price of this compound may exceed that of some traditional materials, it frequently results in lower cumulative costs over time. This reduction manifests through increased battery durability and an extended lifespan, ultimately leading to fewer replacements and reduced maintenance needs.

Manufacturers are increasingly realizing that the long-term financial impact of using this material outweighs the initial cost. Particularly in sectors that rely on uninterrupted service and reliability, such an investment can foster significant savings and boost operational efficiency.

The following comparison provides insights into the economic implications of using this advanced material:

| Cost Factor | Traditional Materials | Zirconium Silicate |

|---|---|---|

| Initial Purchase Price | Lower | Higher |

| Long-Term Savings | Limited | Significant |

| Maintenance Requirements | Frequent replacements often needed | Minimal, resulting in enhanced ROI. |

What Challenges Are Associated with Using Zirconium Silicate?

While zirconium silicate offers substantial benefits, several challenges can impede its integration into battery systems. These hurdles primarily focus on ensuring compatibility with existing battery designs and achieving consistent performance across different applications.

One primary challenge is sourcing high-quality zirconium silicate. Variations in the quality of materials can affect the overall performance of batteries, leading to unpredictable results. Ensuring a reliable supply chain with rigorous quality control processes is essential for manufacturers to address these challenges effectively.

Additionally, technical integration requires careful consideration. Engineers must assess how to effectively incorporate zirconium silicate with other materials and systems within the battery. A lack of compatibility might hinder the anticipated performance enhancements, minimizing the potential advantages.

To summarize the potential challenges, consider the following table:

| Challenge | Description |

|---|---|

| Sourcing Quality Materials | Variations in performance due to fluctuating material quality. |

| Technical Compatibility | The challenge of successfully integrating with existing battery architectures. |

| Consistency of Performance | Variability in performance across different applications and conditions. |

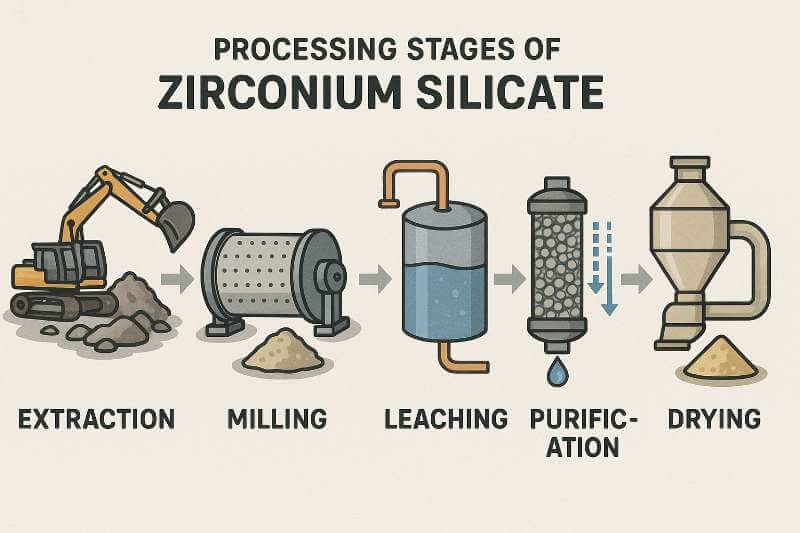

How Is Zirconium Silicate Processed for Battery Use?

Processing zirconium silicate for use in batteries requires specific methodologies to ensure optimal performance in various applications. The extraction and refinement stages are crucial, as care during these phases ensures the final product adheres to the required specifications.

The processing methods typically involve several stages, including extraction, purification, and granulation. During extraction, high-grade zirconium ore is collected. Following this, a purification process removes contaminants that might affect performance. Finally, granulation creates uniform particle sizes, a critical factor for achieving consistent performance in battery applications.

Quality control is paramount throughout the processing journey. Regular testing and monitoring help ensure that the final product meets the rigorous standards necessary for effective use in energy storage.

Here’s a brief summary of the typical processing stages:

| Processing Stage | Description |

|---|---|

| Extraction | Collection of high-grade zirconium ore while minimizing environmental impact. |

| Purification | Removal of contaminants to preserve performance integrity. |

| Granulation | Creation of consistent particle sizes to enhance performance and efficiency. |

| Quality Control | Regular testing and verification to maintain adherence to performance specifications. |

This image illustrates the various processing stages for zirconium silicate, highlighting extraction and purification methods.

What Are the Environmental Considerations of Zirconium Silicate?

When considering the environmental implications of industrial materials, zirconium silicate is no exception. The mining and processing of this material must adhere strictly to ecological standards. Companies must focus on minimizing their environmental footprint to maintain compliance with regulations and public expectations.

As part of this effort, sustainable practices in sourcing zirconium silicate are critical. By adopting responsible mining operations, battery manufacturers can actively contribute to the preservation of ecosystems. This commitment not only enhances their corporate responsibility but also strengthens their market position.

Understanding the lifecycle impact of zirconium silicate—from extraction to disposal—is essential in addressing environmental concerns. Stakeholders are increasingly interested in how their material choices affect overall sustainability, prompting the need for transparency in sourcing and production processes.

Here’s a summary of key environmental considerations:

| Environmental Aspect | Description |

|---|---|

| Mining Practices | Importance of sustainable and responsible extraction methods to preserve local ecosystems. |

| Processing Impact | Focus on minimizing harmful practices during production to reduce ecological damage. |

| Lifecycle Analysis | Evaluating environmental impacts throughout the product lifecycle to inform sustainability efforts. |

How Do Industry Leaders Leverage Zirconium Silicate?

Various companies in different sectors are increasingly turning to zirconium silicate to address the challenges associated with battery performance. Industry leaders such as Tesla and Panasonic are investing in advanced technologies that incorporate this compound. Their strategic initiative to utilize energy-dense materials help enhance product performance, establishing a strong competitive advantage.

These companies often share data highlighting how their innovations link the use of zirconium silicate to improved battery performance metrics. Collaborating on research initiatives allows businesses to develop new methodologies and novel applications of this material, which in turn supports the advancement of the entire battery industry.

For instance, a landmark study conducted by the National Renewable Energy Laboratory showed that the introduction of this material into lithium-ion batteries resulted in a remarkable 25% increase in energy density, underscoring the benefits associated with its application.

| Company | Application | Outcome |

|---|---|---|

| Tesla | Electric Vehicle Batteries | Achieved improved energy density by 20%. |

| Panasonic | Consumer Electronics Batteries | Enhanced performance longevity across multiple product lines. |

| National Renewable Energy Lab | Research and Development | Achieved a 25% increase in energy density through innovative material application. |

What Are the Future Prospects for Zirconium Silicate in Batteries?

The outlook for zirconium silicate in the battery industry seems increasingly optimistic. As various industries strive for higher efficiency and sustainability in energy systems, the potential applications of this material will likely expand. Ongoing research is delving into how this compound can play an integral role in next-generation batteries, particularly as alternatives to conventional technologies emerge.

With the rising adoption of electric vehicles and the growing need for renewable energy storage solutions, this compound aligns perfectly with the objectives of manufacturers looking to innovate. The continuous quest for improved energy solutions will spur on research and development projects that leverage this material’s beneficial properties.

In summary, the future is bright for the application of zirconium silicate in advancing battery technologies, particularly as companies increasingly seek to adopt cleaner and more efficient energy practices. As industries embark on this endeavor, using reliable materials that enhance performance while minimizing environmental impacts remains crucial.

| Future Prospects | Description |

|---|---|

| Expansion Beyond Conventional Use | Potential applications in renewable energy storage. |

| Research and Development | Ongoing studies to identify and cultivate new applications for various technologies. |

| Alignment with Sustainability Goals | Companies focusing on eco-friendly practices and reducing their carbon footprint. |

Conclusion

In conclusion, zirconium silicate offers numerous advantages that can significantly enhance battery performance across various applications. Its unique properties not only improve energy density and stability, but also contribute to cost savings and environmental sustainability. With its growing relevance in modern energy solutions, decision-makers in the industry are well-placed to leverage these benefits for their operational needs. Trust Global Industry for ongoing insights and partnerships that can lead to effective and innovative applications of advanced materials in your business.

FAQ Section

Q1: What is zirconium silicate used for in batteries?

Zirconium silicate is primarily used in batteries to enhance overall performance. It improves ion conductivity and thermal stability, which leads to faster charging, longer lifespan, and increased energy density. This makes it particularly valuable in advanced battery technologies.

Q2: Are there different types of batteries that use zirconium silicate?

Yes, zirconium silicate is beneficial in a variety of battery types, including lithium-ion, solid-state, and lead-acid batteries. Each type leverages the material’s properties to enhance performance, reliability, and safety, making it a versatile option for multiple applications in energy storage.

Q3: What challenges come with integrating zirconium silicate into batteries?

Integrating zirconium silicate can present challenges such as ensuring compatibility with existing materials and achieving consistent performance across different battery designs. Additionally, sourcing high-quality zirconium silicate is critical, as variations in quality can influence battery effectiveness.

Q4: How does the cost of zirconium silicate affect battery manufacturing?

The cost of zirconium silicate can impact battery manufacturing by influencing the overall production expenses. While the initial investment may be higher than traditional materials, the long-term benefits—such as enhanced durability and reduced maintenance costs—often justify the expense over time.

Q5: What are the environmental impacts of zirconium silicate production?

The production of zirconium silicate can have environmental implications, including ecosystem disruption from mining activities. Therefore, sustainable sourcing practices and eco-friendly processing methods are essential to minimize the ecological footprint and ensure responsible use of this material in battery manufacturing.