Manufacturers often face significant obstacles when producing zirconium silicate. These challenges can lead to increased costs, lower quality products, and reduced market competitiveness, especially for Zirconium Silicate products. However, the good news is that there are proven strategies to overcome these hurdles. This article outlines effective trade secrets that can help manufacturers streamline their production processes. With years of experience in the industry, we provide actionable insights that empower businesses to improve their operations and achieve better results.

How Do Production Challenges Affect Zirconium Silicate Manufacturers?

Production challenges can severely disrupt the manufacturing of zirconium silicate. These issues may arise from variables like material quality, equipment failures, or inefficient processes. When manufacturers encounter these problems, the consequences often include delays in production schedules, increased waste, and higher operational costs. This can create a negative spiral impacting profitability and market share.

A deeper look into the common challenges reveals additional layers. For instance, environmental regulations have imposed stringent operational limits, often requiring advanced filtration or waste management systems to stay compliant. Moreover, training deficiencies can lead to unskilled labor, resulting in manufacturing errors.

We must acknowledge the common hurdles manufacturers face. Here are specific challenges they often encounter:

- Inconsistent raw material quality: Variability in supplier quality can lead to batch discrepancies.

- Outdated equipment: Frequent repairs and maintenance can hinder production flow.

- Market volatility: Sudden market changes may result in over-production or stockouts.

- Labor shortages: Difficulties in hiring qualified personnel can affect production levels.

With a recognition of these challenges, manufacturers can take proactive steps to address them. Doing so not only mitigates risks but also enhances overall operational resilience. Companies that prioritize solutions to these challenges often find themselves ahead of the competition.

In summary, acknowledging and understanding production challenges is the first step toward overcoming them. With the right strategies, manufacturers can navigate these hurdles and thrive in a competitive landscape.

This image illustrates the various production challenges that zirconium silicate manufacturers may face, including quality and efficiency issues.

What Are Key Trade Secrets for Efficient Production?

When it comes to efficient zirconium silicate production, several trade secrets can make a significant difference.

First, best practices from leading manufacturers offer valuable insights. These companies often prioritize detailed process documentation, which helps identify inefficiencies quickly. Regularly reviewing these processes is key to continuous improvement.

Additionally, organizations frequently integrate advanced data analytics into their production process, providing insights that allow for more informed decision-making and forecasting. These adaptations can lead to better management of resources.

Another secret involves implementing innovative techniques that boost yield. For instance, improving mixing processes can lead to better uniformity in the final product. Advanced technologies such as real-time monitoring systems can also help in quickly identifying and resolving issues before they escalate.

Quality control measures cannot be overlooked. They play an essential role in ensuring consistency in products. Regular testing and validation of materials throughout the production process can catch issues early, reducing rework and waste.

Here’s the deal: adopting these trade secrets can yield immediate benefits. Manufacturers often see improved throughput, reduced costs, and enhanced product quality when they implement these strategies effectively. In turn, this can lead to higher customer satisfaction and greater market share.

Incorporating industry best practices into daily operations positions manufacturers for long-term success. By focusing on efficiency and quality control, businesses can achieve significant gains in their production capabilities.

| Technology Type | Benefits | Example Implementation |

|---|---|---|

| Automation | Increased speed, reduced errors | Automated assembly lines |

| Monitoring Software | Real-time data, identifying bottlenecks | Process monitoring dashboards |

| Predictive Maintenance | Reduced downtime, longer equipment life | AI-driven maintenance scheduling |

How Can Technology Aid in Overcoming Production Hurdles?

In today’s manufacturing landscape, technology holds the key to addressing many production challenges. Automation is among the most impactful advancements. By automating repetitive tasks, manufacturers can significantly enhance efficiency and reduce human error. This leads to faster production times and consistency in output.

Another vital area is the implementation of advanced monitoring software. These solutions provide real-time data on production processes, identifying inefficiencies and bottlenecks without delay. This visibility allows managers to make informed decisions quickly, optimizing operations.

Moreover, augmented reality (AR) and virtual reality (VR) technologies are emerging as tools for training and troubleshooting. These technologies can simulate real-world scenarios, allowing employees to gain hands-on experience without the risks associated with actual production.

Additionally, artificial intelligence (AI) and machine learning offer predictive maintenance capabilities. Instead of waiting for equipment to fail, these technologies help predict when maintenance is necessary, minimizing downtime and prolonging equipment life.

To illustrate the benefits of technology, consider a manufacturer that integrated an automated mixing system into their process. They reported a 30% increase in production speed and a 15% reduction in material waste within six months. This example underscores the power of technology in modern manufacturing.

Leveraging the right technological solutions can dramatically improve production outcomes. By adopting these innovations, manufacturers are not just keeping up; they are setting the stage for future success.

| Technology Type | Benefits | Example Implementation |

|---|---|---|

| Automation | Increased speed, reduced errors | Automated assembly lines |

| Monitoring Software | Real-time data, identifying bottlenecks | Process monitoring dashboards |

| Predictive Maintenance | Reduced downtime, longer equipment life | AI-driven maintenance scheduling |

What Role Does Material Sourcing Play in Manufacturing?

Material sourcing is a critical component of zirconium silicate production. Quality raw materials directly influence the final product’s quality. Manufacturers must ensure their suppliers provide consistent, high-grade materials to achieve optimal results.

Choosing the right suppliers is essential. Strong relationships foster reliability and consistency. Engaging in strategic partnerships with trusted suppliers often leads to better pricing and more favorable terms.

Additionally, industry certifications of suppliers can further guarantee quality. By selecting suppliers that adhere to recognized quality standards, manufacturers can diminish the risk of poor-quality inputs.

Cost optimization in material procurement can also yield significant savings. By centralizing purchasing and negotiating bulk deals, manufacturers can reduce overall material costs. However, quality should never be compromised for the sake of price. It’s vital to strike a balance between cost and material reliability.

This might surprise you: companies that develop robust sourcing strategies often report lower production costs and better product quality. By focusing on material quality and supplier relationships, manufacturers can strengthen their production capabilities.

Here are additional strategies for effective material sourcing:

- Diversification of Suppliers: Reducing dependency on single suppliers mitigates risks associated with supply chain disruptions.

- Establishing Long-Term Relationships: Fostering good rapport can lead to priority treatment during shortages or crises.

- Conducting Regular Audits: This ensures that suppliers consistently meet quality standards.

- Incorporating Technology: Using software for supply chain management can streamline ordering and logistics.

In summary, diligent material sourcing can streamline production processes and enhance product quality. Manufacturers that take this aspect seriously often see considerable improvements in efficiency and output.

| Sourcing Strategy | Benefits | Example Action |

|---|---|---|

| Supplier Engagement | Reliability, consistent quality | Long-term contracts |

| Centralized Purchasing | Cost savings, bulk pricing | Negotiating with suppliers |

| Quality Checks | Ensuring high-grade inputs | Regular supplier audits |

How to Optimize Manufacturing Processes for Better Outcomes?

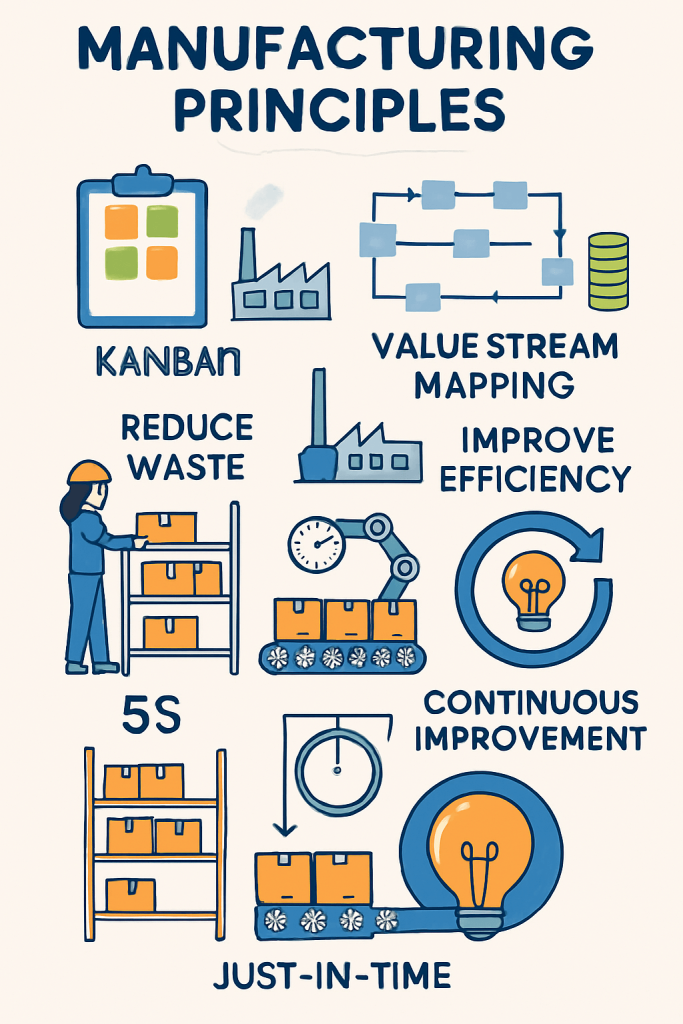

Optimizing manufacturing processes is vital for increasing efficiency and product quality. One effective approach is adopting lean manufacturing principles. Lean focuses on minimizing waste while maximizing value to the customer. This concept encourages manufacturers to evaluate every process critically, identifying areas that can be streamlined or improved.

Additionally, continuous improvement methodologies, such as Six Sigma, can drive optimization efforts. These methods help in identifying defects in processes and establishing solutions to enhance overall quality.

Identifying waste is another key focus area. Manufacturers can reduce costs significantly by analyzing their workflows and identifying unnecessary steps or redundancies.

So, what’s the takeaway? Investing in process optimization pays off in the long run. Enhanced efficiency reduces costs, improves quality, and increases customer satisfaction.

Companies that commit to optimizing their processes often find themselves leading their industries in terms of productivity and operational excellence.

| Process Optimization Method | Benefits | Implementation Steps |

|---|---|---|

| Lean Manufacturing | Reduced waste, increased value | Evaluate current workflows |

| Continuous Improvement | Better quality, fewer defects | Implement Six Sigma |

| Waste Analysis | Lower costs, streamlined operations | Identify redundancies |

This image illustrates lean manufacturing strategies aimed at reducing waste and increasing efficiency in production processes.

What are Effective Quality Assurance Techniques?

Quality assurance (QA) is a cornerstone of successful manufacturing. Implementing effective QA techniques ensures products meet customer expectations and industry standards.

Firstly, manufacturers should adopt relevant standards and certifications, such as ISO 9001. These guidelines help establish robust quality management systems, fostering consistency throughout production.

Secondly, ongoing testing and validation processes are vital. Regularly testing raw materials and finished products ensures that they meet quality specifications. This effort prevents defective products from reaching customers and maintains the manufacturer’s reputation.

Guess what? Companies that prioritize quality assurance often experience lower rates of returns and customer complaints. This leads to higher customer loyalty and improved market standings.

In summary, effective quality assurance is not just about meeting standards; it’s about building trust with customers. For manufacturers, investing in QA processes yields tangible benefits in customer satisfaction and business reputation.

| QA Technique | Benefits | Example Implementation |

|---|---|---|

| Standards and Certifications | Consistency, trust | Implement ISO systems |

| Regular Testing | Early detection of defects | Routine product quality checks |

| Customer Feedback Mechanisms | Improvement opportunities, satisfaction | Surveys and feedback loops |

How Can Manufacturers Foster Collaboration and Communication?

Effective collaboration and communication play a crucial role in smooth manufacturing operations. It’s essential for teams to work together to address challenges and optimize production.

Encouraging teamwork begins with cultivating a collaborative culture. This involves fostering open communication, where team members feel safe sharing ideas and concerns. Regular meetings and open-door policies can facilitate this healthy exchange.

Utilizing collaboration tools and platforms greatly enhances this aspect. Tools like project management software allow teams to share information and stay aligned on goals. Instant messaging platforms can also expedite communication, reducing delays caused by waiting for responses.

To build a robust communication framework, manufacturers can also adopt team-building activities. These activities not only enhance interpersonal relationships but also improve overall teamwork.

Here’s the kicker: companies that invest in fostering collaboration often see improved morale and productivity. When employees feel connected and engaged, high-performance results follow.

In summary, effective collaboration and communication boost operational efficiency. By investing in these areas, manufacturers can build stronger teams and achieve better results.

Here are various tools and methods to enhance communication and collaboration within manufacturing teams:

Creating Cross-Functional Teams: Encouraging collaboration across different departments enhances understanding and efficiency.

Regular Team Workshops: Engaging teams in workshops encourages collaboration and fosters a learning environment.

Integration of Collaborative Software: Using platforms like Slack or Microsoft Teams to facilitate quick communication.

Feedback Mechanisms: Establishing processes to gather and act on employee feedback can improve morale.

| Collaboration Strategy | Benefits | Example Tools |

|---|---|---|

| Team Meetings | Enhanced communication, idea sharing | Weekly planning sessions |

| Open-Door Policies | Trust-building, quick problem-solving | Encouraging informal discussions |

| Project Management Software | Improved project tracking, alignment | Tools like Trello or Asana |

What are the Best Practices in Training and Skill Development?

Training and skill development are fundamental elements of manufacturing success. Identifying skill gaps within the workforce is the first step. Regular assessments and performance reviews help pinpoint areas where employees may need improvement or further training.

Once gaps are identified, manufacturers should implement targeted training programs. These programs can focus on specific skills or technologies pertinent to the production process, ensuring employees are well-equipped for their roles.

Emphasizing ongoing education and skill upgrades is equally critical. An investment in continuous learning keeps the workforce current with industry changes and technological advancements.

You may find this surprising: organizations that prioritize employee training report higher productivity and lower turnover rates. When employees feel supported in their professional growth, they are more likely to stay and contribute positively to the organization.

To sum up, effective training and skill development lead to a more competent workforce. By investing in their teams, manufacturers create a solid foundation for ongoing success.

| Training Strategy | Benefits | Example Actions |

|---|---|---|

| Skill Gap Assessment | Identify training needs | Regular performance reviews |

| Targeted Training Programs | Improved employee competence | Workshops and on-the-job training |

| Ongoing Education | Adaptability, knowledge updates | Online courses and certifications |

This image depicts manufacturing workers engaged in training and skill development sessions to enhance their capabilities.

How Can Manufacturers Leverage Supply Chain Management?

Supply chain management plays a critical role in manufacturing efficiency. Understanding the dynamics involved allows manufacturers to optimize their operations significantly.

A key element of effective supply chain management is reducing lead times. Streamlining processes with suppliers, such as implementing just-in-time inventory systems, helps minimize delays associated with stock replenishment.

Effective inventory management practices will also enhance operations. This entails maintaining optimal stock levels to meet production demands without overstocking, which can tie up resources unnecessarily.

Here’s what you need to know: companies that enhance their supply chain management often experience lower costs and improved service levels. By maintaining a smooth flow of materials, manufacturers can boost productivity and respond quickly to market demands.

In conclusion, leveraging effective supply chain management practices creates a more responsive and efficient operation. Manufacturers who focus on mastering their supply chain can achieve lasting competitive advantages.

| Supply Chain Strategy | Benefits | Example Practices |

|---|---|---|

| Just-In-Time Inventory | Reduced lead times, lower storage costs | Collaborating closely with suppliers |

| Effective Inventory Management | Optimized stock levels, cost savings | Regular inventory assessments |

| Supplier Audits | Improved quality and reliability | Routine evaluations of supplier performance |

What are Common Regulatory Compliance Issues?

Manufacturers must navigate various regulatory compliance issues that impact the production of zirconium silicate. Understanding these regulations is vital to avoid legal penalties and maintain industry credibility.

A broad overview of regulations includes quality standards, environmental regulations, and safety protocols. Not adhering to these laws can lead to hefty fines, production halts, and damage to reputation.

Best practices for compliance involve maintaining detailed documentation for all processes and audits. This transparency fosters accountability and makes it easier for manufacturers to demonstrate their adherence to regulations.

Let’s be clear: manufacturers that prioritize compliance often enjoy smoother operations and stronger relationships with regulatory bodies. This can result in fewer disruptions and a more stable operating environment.

In summary, staying compliant with relevant regulations is crucial for manufacturers. By focusing on regulatory adherence, companies can protect themselves from risks and focus on quality production.

| Compliance Area | Common Issues | Best Practices |

|---|---|---|

| Quality Standards | Failing to meet testing requirements | Regular training and audits |

| Environmental Regulations | Non-compliance with waste disposal | Implementing eco-friendly processes |

| Safety Protocols | Unsafe working conditions | Strict enforcement of safety policies |

How Can Manufacturers Prepare for Future Challenges?

Preparing for future challenges is essential for any manufacturer. As market dynamics shift, businesses must anticipate changes in demand, technology, and regulations. Staying ahead of these changes can significantly impact long-term success.

One effective way to prepare is by investing in research and development (R&D). R&D allows manufacturers to innovate their products and processes continually. This proactive approach not only leads to better products but also keeps companies competitive.

Additionally, manufacturers should monitor trends in their industry. Keeping an eye on emerging technologies and shifts in consumer preferences can provide valuable insights for strategic planning.

Here’s a critical point to note: companies that invest in future preparedness often establish more sustainable business practices and a loyal customer base. By being proactive rather than reactive, manufacturers can navigate uncertainties with greater confidence.

In summary, preparation for future challenges is crucial for long-term viability. By focusing on R&D and market trends, manufacturers can build a resilient foundation for growth.

| Preparation Strategy | Benefits | Example Actions |

|---|---|---|

| Invest in Research & Development | Innovation, competitive edge | Product testing and exploration |

| Trend Monitoring | Informed decision-making | Regular market analysis meetings |

| Strategic Planning | Flexibility and adaptability | Developing contingency plans |

Conclusion

Throughout this article, we have explored how manufacturers can overcome challenges related to zirconium silicate production. From understanding production hurdles to implementing effective technology solutions, each strategy contributes to better efficiency and product quality. In particular, focusing on trade secrets and best practices can yield significant improvements.

By utilizing insights from this article, manufacturers can enhance their operations and improve their market position. At Global Industry, we are committed to providing tailored solutions to help you succeed. Contact us today to learn how we can partner with you to tackle your unique manufacturing challenges.

FAQ Section

Q1: What are the biggest production challenges for manufacturers? Manufacturers often face issues like supply chain disruptions, quality control failures, and inefficiencies in production processes.

Q2: How can technology improve zirconium silicate production? Automation and advanced monitoring software can enhance efficiency, reduce human error, and optimize production timelines.

Q3: Why is quality assurance crucial in the manufacturing process? Quality assurance ensures that the final product meets industry standards, reducing the risk of defects and enhancing customer satisfaction.

Q4: What is the role of material sourcing in production? High-quality raw materials are essential for optimal production, as they directly impact product quality and production costs.

Q5: How can companies stay compliant with manufacturing regulations? By regularly updating their practices according to industry standards and maintaining thorough documentation, companies can ensure compliance.