Zircon sand plays a pivotal role in various industries, yet many decision-makers struggle with understanding the complexities of its refining process. This article addresses your concerns by breaking down the essential steps involved in refining zircon sand with clarity and precision. You will gain a comprehensive view of the intricacies of this process, enabling you to make informed decisions for your business operations. With decades of expertise in the mineral processing field, our insights will provide you with practical knowledge and solutions to enhance your understanding of zircon sand refining.

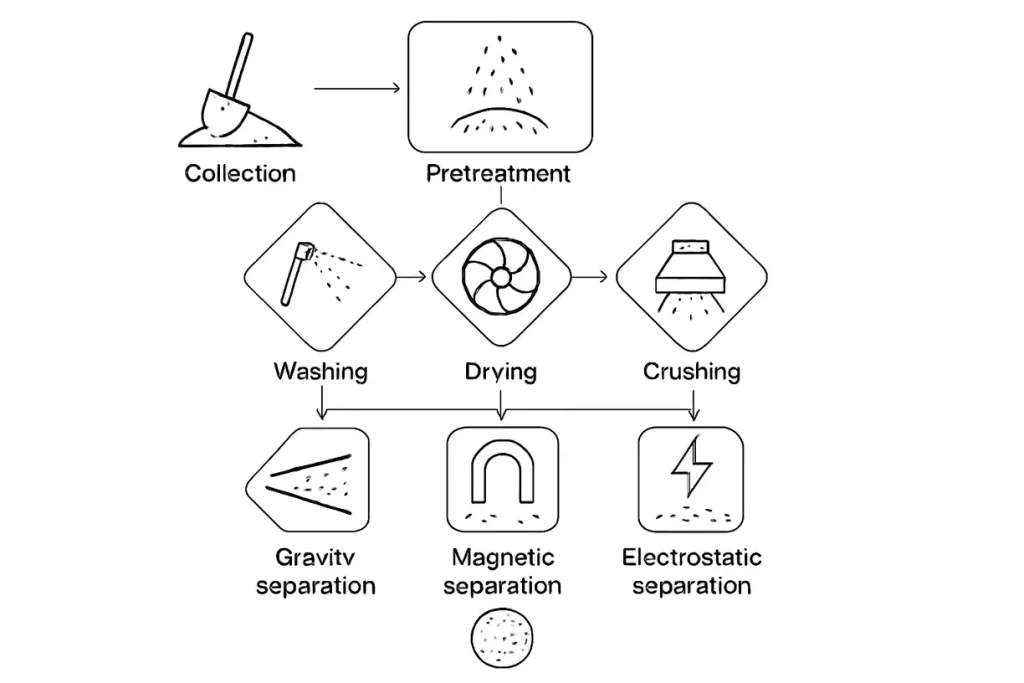

The image depicts a flowchart illustrating the key steps in zircon sand refining, including collection, pre-processing, and separation.

What Are the Essential Steps in Refining Zircon Sand?

Refining zircon sand involves several critical steps that transform raw material into a valuable product suitable for numerous applications. Initially, the process starts with collecting raw zircon sand from various sources, including beach and inland deposits. This initial collection is essential, as the quality of the zircon sand directly influences the efficacy of subsequent refining operations. Raw zircon sand contains impurities, such as minerals and other unwanted elements, that must be meticulously removed to produce high-purity zircon.

After collection, the raw sand undergoes a pre-processing stage where it is cleaned to eliminate physical contaminants. This step typically involves washing and screening the sand to separate larger particles, dust, and debris. It’s important to use clean water to avoid introducing new contaminants into the mix. Once the sand is cleaned, it goes through a separation process, utilizing methods such as gravity separation or magnetic separation to eliminate unwanted materials that do not contribute to the zircon content.

The next critical step is chemical treatment, which involves treating the zircon sand with acids and other chemicals designed to remove additional impurities. This treatment increases the purity level of zircon significantly, preparing it for further processing stages. Through this stage, manufacturers can ensure that the zircon produced will meet stringent industry standards. Finally, the refined zircon sand undergoes quality control checks to ensure that it meets required industry specifications before being packaged and distributed for various applications.

Here’s the thing: Each of these steps contributes to the overall quality and effectiveness of the refined product, making it essential for manufacturers to comprehend these processes fully. By understanding each stage, companies can optimize their operations, reduce waste, and enhance the final product’s purity.

Why Is Zircon Sand Important for Industries?

Zircon sand plays a vital role in many industrial applications, primarily due to its unique properties that set it apart from other materials. It is widely used in the ceramics industry for making tiles, sanitary ware, and other household items. In these applications, zircon enables products to become more robust and resistant to wear over time. The use of zircon in ceramics also enhances aesthetic appeal, allowing for vibrant colors and smoother finishes, which are essential in both consumer and industrial markets.

Additionally, zircon sand finds significant applications in the glass industry. It acts as a filler in the production of glass products, preventing discoloration and ensuring the creation of smooth surfaces. The presence of zircon improves thermal stability, making glass products more durable and suitable for a range of applications, including containers, windowpanes, and decorative items. Furthermore, the refractory industry utilizes zircon for its high-temperature resistance, particularly in applications like furnace linings and shapes, where it can withstand extreme heat without degrading.

The demand for high-purity zircon is continuously rising, especially as industries begin to place more emphasis on environmental sustainability and the search for reliable materials. Understanding the refining process becomes critical for stakeholders who are keen to capitalize on the benefits of zircon sand. By efficiently refining this mineral, businesses can ensure that they meet the growing market demand for high-quality products.

Think about it: As various industries continue to seek reliable sources of zircon, companies involved in mining and refining must not only focus on quality but also strive for consistency in their operations to maintain customer trust and satisfaction.

Table 1: Applications of Zircon Sand in Various Industries

| Industry | Application | Benefits |

|---|---|---|

| Ceramics | Tiles, sanitary ware | Increases durability and aesthetics |

| Glass | Filler in glass products | Prevents discoloration, promotes smoothness |

| Refractory | Furnace linings, shapes | High-temperature resistance |

| Electronics | Circuit boards, semiconductor applications | Enhances electrical performance |

| Paints and Coatings | Opacifier | Improves coverage and finish |

What Raw Materials Are Needed for Zircon Sand Refining?

Before refining zircon sand, understanding the raw materials needed for this process is crucial for achieving optimal results. The primary raw material is, of course, raw zircon sand, which serves as the foundation for the entire refining process. The quality of the raw zircon significantly influences the purity and efficiency of the final product.

Apart from zircon sand, chemicals for refining, such as hydrochloric acid and sulfuric acid, are essential to effectively remove impurities that remain during the treatment phase. These acids facilitate the breakdown of unwanted minerals, allowing for a cleaner final product. Additionally, various additives might also be used to enhance the specific characteristics of the refined zircon. These could include agents that modify particle shape, improve flowability, or enhance the thermal properties of the finished zircon sand.

Summarizing the key raw materials used in zircon sand refining provides clarity on the necessary components:

● Raw zircon sand

● Hydrochloric acid

● Sulfuric acid

● Additives as needed

Now, here’s something to consider: each material impacts both the efficiency of the refining process and the quality of the final product.

Table 2: Key Raw Materials Used in Zircon Sand Refining

| Material | Purpose | Source |

|---|---|---|

| Raw zircon sand | Foundation material for refining | Beach or inland deposits |

| Hydrochloric acid | Removes impurities during chemical treatment | Industrial production |

| Sulfuric acid | Used for chemical refining | Industrial production |

| Specific additives | Enhances characteristics of the final product | Supplier based on formulation |

How Is Zircon Sand Pre-Processed Before Refining?

Pre-processing zircon sand is crucial for ensuring efficiency throughout the overall refining process. The initial step in pre-processing involves washing the raw sand with clean water. This step is imperative as it removes surface dirt, clay, and other contaminants that could affect the quality of the final product if not addressed.

After washing, the sand is screened to separate finer particles from coarser ones. This process is important because larger particles may contain unwanted minerals or impurities that could interfere with the refining process. Additionally, the screening ensures a uniform size distribution of the zircon sand, which is pivotal for subsequent steps. Following screening, the sand often undergoes gravity separation to separate heavier materials from lighter ones. Using specific equipment, such as spiral concentrators, allows operators to maximize yield by ensuring that only high-quality zircon progresses to the next refinement stages.

These pre-processing steps lead to the effective preparation of zircon sand, resulting in a cleaner, more homogeneous product.

The image illustrates the pre-processing stage of zircon sand, highlighting washing and screening equipment in a processing facility.

By the way: effective pre-processing leads to higher purity levels in the final product, which is essential for maintaining market competitiveness.

Table 3: Pre-Processing Steps for Zircon Sand

| Step | Description | Equipment Used |

|---|---|---|

| Washing | Removes surface contaminants | Wash tanks |

| Screening | Separates larger particles | Vibrating screens |

| Gravity Separation | Separates heavy materials | Spiral concentrators |

| Drying | Ensures moisture removal | Drying ovens |

What Are the Main Methods of Zircon Sand Refining?

Several methods can be employed when refining zircon sand, each offering different levels of efficacy, cost, and quality of the final product. The most common methods used in the industry include:

● Gravity separation: This method utilizes the differences in density between zircon and other minerals to separate them through physical means. It is a simple yet effective technique for achieving reasonable purity levels.

● Magnetic separation: This method removes magnetic impurities from the zircon sand, improving overall purity levels. It typically operates on a principle where the magnetic minerals are attracted to a magnet and separate from non-magnetic zircon.

● Chemical processing: Involves treating the sand with strong acids to dissolve impurities. This method yields the highest purity levels but may involve greater costs and safety precautions due to the nature of acids used.

Each method has its unique advantage, which means that manufacturers must assess their operational goals carefully. For example, gravity separation is often more cost-effective and suitable for large-scale operations, while chemical processing may be warranted when the highest purity is required.

Here’s the deal: Manufacturers must assess their operational goals and choose the appropriate method that balances cost, efficiency, and desired purity levels to optimize their operations.

Table 4: Comparison of Zircon Sand Refining Methods

| Refining Method | Advantages | Disadvantages | Cost |

|---|---|---|---|

| Gravity Separation | Cost-effective | May not yield highest purity | Low |

| Magnetic Separation | Effectively removes magnetic impurities | Limited to magnetic particles | Moderate |

| Chemical Processing | High purity levels | Uses hazardous materials, higher cost | High |

How Does the Separation Process Work?

The separation process is a crucial step in refining zircon sand. This phase aims to eliminate any unwanted materials and enhance the purity of the zircon. Different techniques used for separation complement each other, as they target various impurities. The most common techniques include gravity separation and magnetic separation.

In gravity separation, zircon sand is mixed with water and then passed through a series of screens or spirals. The slurry undergoes centrifugal forces, allowing heavier zircon particles to settle due to their weight, while lighter impurities are washed away effectively. This method capitalizes on the physical properties of the materials.

Magnetic separation, on the other hand, involves passing the zircon sand through a magnetic field. This technique is particularly useful for removing magnetic minerals, like ilmenite or hematite, that are often found in lower-grade zircon sand. The combined use of both techniques often yields a superior quality of zircon.

It’s important to note: A thorough separation process is essential for manufacturers aiming to supply high-purity zircon for various industrial applications.

Table 5: Separation Techniques Overview

| Technique | How It Works | Effectiveness |

|---|---|---|

| Gravity Separation | Uses water and gravity to separate based on density | Effective for high-density materials |

| Magnetic Separation | Uses magnets to attract and separate magnetic materials | Highly effective for magnetic impurities |

What Role Does Chemical Treatment Play in Refining?

Chemical treatment is a vital part of the zircon sand refining process. This step is employed to eliminate any residual impurities that may remain after the physical separation. Chemicals such as hydrochloric acid and sulfuric acid are often utilized for this purpose, as they can break down unwanted minerals at a molecular level.

The chemical treatment process begins with mixing the zircon sand with the acid solution in a controlled environment to minimize hazards. The acid reacts with the impurities, dissolving them and allowing for their subsequent removal. Following this reaction, the sand is washed thoroughly to eliminate all chemical residues, ensuring that only clean and pure zircon remains.

But that’s not all: Chemical treatment not only enhances the purity of zircon sand but also adjusts its characteristics to meet specific industry standards regarding thickness, flowability, and thermal stability. This adjustment is crucial for businesses looking to form reliable partnerships with clients who require customized specifications.

This step is crucial for businesses looking to deliver consistently high-quality products to end-users across different industries.

How Is Quality Control Managed During Refining?

Quality control is a vital process throughout zircon sand refining, ensuring that the end product adheres to established industry standards. There are several key aspects to quality control management that every facility must consider.

Firstly, routine sampling of raw materials and intermediate products is essential. Regularly testing samples helps catch potential issues early in the refining process, allowing companies to address them before they escalate.

Secondly, testing parameters such as chemical composition, grain size, and purity are continuously monitored during refining. Using advanced testing equipment, such as X-Ray fluorescence and laser diffraction, guarantees accurate results consistently.

Finally, companies must adhere to specific regulatory certifications, ensuring compliance with industry standards like ISO and environmental regulations. This adherence fosters trust and reliability among manufacturers and end-users alike, reinforcing reputation and competitive advantage.

You might find this interesting: Ensuring rigorous quality control throughout refining stages not only enhances product quality but also strengthens customer relationships and market positioning. Companies are often prized for their reliability and consistency, leading to long-term partnerships.

What Are the Environmental Considerations in Zircon Refining?

Zircon sand refining is not without its environmental impact, and awareness of these considerations is growing among businesses. The extraction and processing of zircon can disrupt local ecosystems and generate waste products that must be managed.

One significant concern involves water usage during washing and chemical treatment processes. Excessive water consumption can lead to resource depletion in local areas. Additionally, the chemicals used in the refining process may pose risks if they are not handled correctly.

Companies are increasingly implementing sustainable practices to mitigate these environmental impacts. This may include using less harmful chemicals, recovering wastewater for reuse, and restoring habitats post-mining.

It’s paramount for businesses to strike a balance between production needs and environmental stewardship. Doing so reflects positively on their brand image and compliance with regulatory standards.

Table 6: Environmental Impact Considerations

| Environmental Aspect | Potential Impact | Mitigation Strategies |

|---|---|---|

| Water Usage | Depletion of local water resources | Recycling and efficient use |

| Chemical Management | Risks associated with hazardous waste | Using biodegradable chemicals |

| Habitat Disruption | Disruption to local ecosystems | Post-mining restoration |

| Waste Generation | Contribution to pollution during processing | Implementing waste reduction strategies |

What Are the Economic Implications of Zircon Sand Refining?

The economic aspects of zircon sand refining can significantly influence business viability and growth potential, making it an essential consideration for management. One of the primary factors is the cost of raw materials and refining processes. Fluctuations in prices often depend on location, availability, and technological advances in refining methods. Careful management of these variables is crucial for enhancing profitability.

Understanding market demand for refined zircon products is equally important. As industries evolve, there is an increased focus on sustainable materials. Manufacturers must remain vigilant and adjust their outputs according to consumer preferences and regulatory shifts, potentially pivoting to more environmentally friendly practices to capture market share.

Finally, efficiency in production plays a vital role in determining profitability. Streamlining operations, optimizing labor costs, and innovating resource management can help companies reduce waste and increase their overall margins.

Here’s something to think about: Keeping a close eye on economic factors such as raw material costs, market demand, and production efficiency can lead to strategic business decisions that support long-term success in a competitive landscape.

How Can Businesses Optimize Their Zircon Sand Refining Processes?

Optimizing zircon sand refining processes involves a combination of improving efficiency, quality, and minimizing costs. One effective strategy is to invest in advanced technologies that enhance separation and refining processes.

Utilizing automation and digitalization can help streamline operations. For example, real-time monitoring of equipment can prevent breakdowns and improve uptime.

Additionally, companies should focus on employee training to ensure that staff are knowledgeable about best practices in refining. Regular training fosters a culture of continuous improvement and keeps everyone aligned with the company’s goals.

Finally, establishing strong relationships with suppliers and clients can lead to collaborations that promote innovation in refining practices.

So, here’s the takeaway: optimizing zircon refinements not only boosts productivity but also enhances overall business performance.

Table 7: Strategies for Optimizing Refining Processes

| Strategy | Implementation Details | Expected Outcomes |

|---|---|---|

| Advanced Technologies | Invest in modern equipment and software | Improved efficiency and accuracy |

| Employee Training | Conduct regular training sessions | Enhanced staff knowledge |

| Supplier Collaboration | Build long-term partnerships with suppliers | Better resource management |

| Process Automation | Utilize automated systems for monitoring | Reduced downtimes |

What Future Trends Are Emerging in Zircon Sand Refining?

As industries evolve, so too does zircon sand refining. Emerging trends highlight an increased focus on sustainability and technology, allowing businesses to respond to market demands more efficiently. For example, many companies are adopting green chemistry methods to reduce chemical waste and minimize environmental harm. These practices not only help compliance but also enhance brand reputation.

Moreover, advancements in automation and data analytics are reshaping how refining operations function. Companies leveraging these technologies can achieve greater accuracy and efficiency, leading to consistently higher-quality products. Smart systems can predict equipment failures, allowing for proactive maintenance and improved uptime.

Additionally, modular processing plants are gaining popularity, allowing for flexible production capabilities tailored to changing market demands and customer specifications. Companies embracing this flexibility can efficiently respond to fluctuating market needs.

Looking ahead: Keeping an eye on these emerging trends can help businesses stay competitive in the dynamic market landscape and position themselves as leaders within the zircon sand refining industry.

Conclusion

In summary, understanding the essential steps in refining zircon sand is fundamental for any business involved in this sector. From the critical raw materials to the separation techniques employed, each facet plays a significant role in the final product’s quality. A key takeaway is that optimizing your refining process can lead to significant benefits, including cost-efficiency and product excellence. Global Industry stands ready to support your operations with resources and expertise tailored to your refining needs. For further insight into improving your zircon sand refining process, consider partnering with us to explore innovative solutions.

FAQ Section

Q1: What is the purpose of zircon sand refining?

The purpose of zircon sand refining is to extract high-purity zircon, which is essential for various industrial applications. This refined zircon is used in manufacturing ceramics, glass, and electronic components, where its unique properties contribute to performance and quality.

Q2: What industries use zircon sand?

Zircon sand is primarily utilized in a range of industries, including ceramics for tiles and sanitary ware, glass manufacturing for improved appearance, and refractories for high-temperature applications. Its versatility makes it a crucial raw material across different sectors.

Q3: How do chemical treatments affect zircon refinements?

Chemical treatments, such as using acids, play a vital role in enhancing the quality and purity of zircon. These processes remove unwanted impurities and minerals, allowing the refined zircon to meet specific industry standards and improve performance in final products.

Q4: What are the environmental impacts of zircon sand refining?

The refining process of zircon sand can lead to various environmental issues, including resource depletion and habitat disruption. Companies are increasingly adopting sustainable practices, such as reducing water usage and minimizing chemical waste, to lessen their ecological footprint.

Q5: What are the costs associated with zircon sand refining?

Costs for zircon sand refining can vary widely due to factors like raw material quality, refining methods, and market demand. Investment in technology and efficient processes is crucial for maintaining profitability, especially in a competitive industry.