The future of 3D printing holds great promise, but many businesses are left wondering about the materials that can optimize their manufacturing processes. Zircon sand is emerging as a strong candidate, thanks to its unique properties and benefits. However, many companies face challenges in sourcing and utilizing this material effectively. This article aims to address key concerns related to zircon sand in 3D printing while highlighting its advantages and applications. By the end of this article, you’ll have a clear understanding of how this mineral can enhance your operations and help you stay competitive in the market.

The interest in zircon sand is growing rapidly because it offers specific advantages that common materials do not. For manufacturers seeking ways to produce durable and visually appealing products, the exploration into zircon sand opens new avenues. With the increasing complexity of designs in 3D printing, selecting the right material is essential to achieving high-quality results. Businesses that adapt quickly to incorporate materials like zircon can not only improve their production but also meet the ever-evolving standards of various industries.

What Are the Benefits of Using Zircon Sand in 3D Printing?

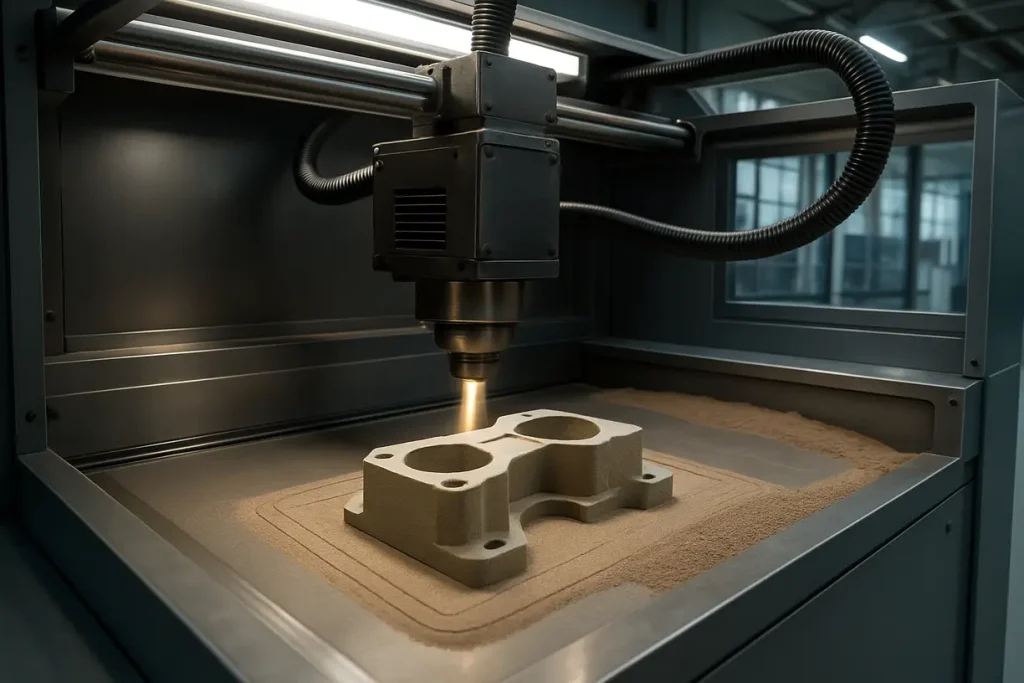

Zircon sand offers a wealth of advantages when it comes to 3D printing. First and foremost, its durability stands out as a primary benefit. Products made from this material are more resistant to wear and tear, making them suitable for demanding applications. Parts used in engineering or industrial contexts frequently encounter harsh conditions, and utilizing zircon can significantly reduce the rate of failure. This durability extends the lifespan of the printed items, ultimately saving costs for businesses that might otherwise face frequent replacements.

Moreover, zircon sand provides an improved surface finish. Compared to many other materials, parts printed with zircon have a smooth and high-quality appearance. This enhances not only the aesthetic value of the final product but also its functional performance. Industries like automotive manufacturing, where the appearance of components can influence consumer perception, greatly benefit from this quality. A polished surface often leads to better adhesion in subsequent coatings or treatments, streamlining further processing.

Heat resistance is another significant benefit of utilizing zircon. This material can withstand high temperatures that may cause other materials to warp or melt. This property enables the production of components used in extreme conditions, such as engine parts in automotive applications. Industries that operate under such circumstances can rely on zircon for reliable performance, keeping safety and efficiency as priorities.

This image illustrates the application of zircon sand in industrial 3D printing processes.

In summary, the distinct advantages this mineral presents create a strong case for its adoption. The combination of durability, aesthetic quality, and heat resistance makes it an ideal solution for enterprises focused on high standards and innovative applications.

How Does Zircon Sand Compare to Other Materials?

When evaluating zircon sand alongside other common 3D printing materials, several aspects come into play. Cost efficiency, for instance, is crucial in making material selections. While zircon sand may be more expensive than materials like PLA or ABS upfront, its longevity often leads to more considerable savings in the long term. By focusing on that aspect, a business can determine its best cost-to-benefit ratio, especially for parts requiring durability.

Next, let’s consider performance metrics. Zircon exhibits reduced shrinkage rates compared to many plastics during the cooling process. This property leads to greater dimensional accuracy, a crucial factor in industries where precision is paramount, such as aerospace and medical device manufacturing. To spice it up, here are some specific comparisons to highlight why zircon might be favorable:

- Mechanical Strength: Zircon typically maintains a higher tensile strength, making it less prone to breaking under stress.

- Thermal Stability: It remains stable in extreme temperatures, maintaining physical properties when many polymers would start to degrade.

- Dimensional Stability: Its low thermal expansion rate means parts retain their dimensions better when subjected to fluctuating temperatures.

Lastly, industries have varying applications for different materials. Plastic materials might offer flexibility for prototypes, whereas zircon is ideal for producing end-use parts that demand robustness. As a result, the choice of material often depends on specific project requirements—this could be weight, strength, or even compatibility with other substances.

Table: Comparison of Zircon Sand with Other 3D Printing Materials

| Material | Cost | Durability | Surface Finish | Heat Resistance | Applications |

|---|---|---|---|---|---|

| Zircon Sand | High | Excellent | High | Excellent | Aerospace, Automotive |

| PLA | Low | Moderate | Moderate | Low | Prototyping, Toys |

| ABS | Moderate | Good | Moderate | Moderate | Functional Parts |

| Nylon | High | Good | High | Moderate | Textiles, Durables |

What Challenges Are Associated With Zircon Sand in 3D Printing?

Despite its many benefits, utilizing zircon is not without challenges. One key issue companies face is sourcing and supply chain reliability. The mining and extraction of this valuable mineral are concentrated in specific geographic regions, making it vulnerable to geopolitical factors and market fluctuations. This situation can lead to inconsistent availability for manufacturers, affecting production schedules.

Moreover, processing difficulties also arise when using this material. The zircon requires specific handling and machine settings to achieve optimal results in 3D printing, which might not be compatible with all existing equipment. Companies may need to invest in training for their workforce or modify machinery to meet these new requirements, which could incur additional costs.

Environmental considerations must not be overlooked, either. While zircon is a naturally occurring mineral, the extraction process can have ecological impacts if not conducted responsibly. Companies should strive to adopt sustainable mining practices that minimize their carbon footprint and enhance community relations. Here are several points to consider for mitigating these challenges:

- Source Responsibly: Establish relationships with suppliers that prioritize sustainable extraction methods.

- Invest in Technology: Implement advanced technology that can handle zircon effectively.

- Monitor Supply Chains: Utilize software or services that provide visibility into supply chain fluctuations.

How Is Zircon Sand Processed for 3D Printing?

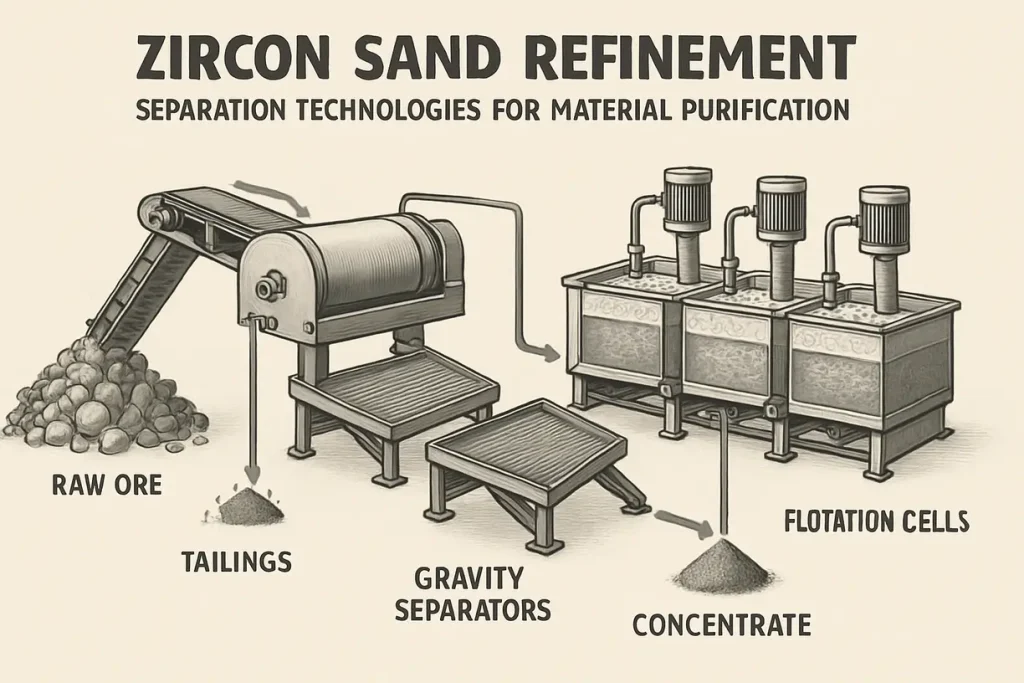

Processing zircon for use in 3D printing involves several key stages to ensure quality and consistency. Initially, the raw material is mined and extracted from the earth, primarily in coastal regions where deposits are abundant. This step requires specialized machinery and careful planning to minimize environmental damage.

Once extracted, the zircon undergoes a refinement process designed to eliminate impurities. This purification is critical, as contaminants can significantly affect both the printing process and the final quality of the printed products. Manufacturers typically use techniques such as dry and wet separation methods to purify zircon effectively.

Quality control is also crucial at this stage. Companies must perform rigorous testing to ensure that the zircon meets industry standards. These tests generally include assessing factors like particle size distribution, chemical composition, and thermal properties. By maintaining high-quality inputs, businesses can achieve better output results in their 3D printing processes.

To further inform you, here are essential characteristics tested during quality control:

- Particle Size: Determines melting and flow properties during printing.

- Purity: High purity ensures no unwanted reactions during printing.

- Thermal Conductivity: Impacts the printing temperature settings required for the best results.

Table: Zircon Sand Processing Steps

| Step | Description |

|---|---|

| Mining | Extraction of zircon from suitable locations |

| Refinement | Elimination of impurities through separation methods |

| Quality Control | Testing material to meet industry standards |

This image shows the refinement process where impurities are removed from zircon sand.

What Industries Could Benefit from Zircon Sand in 3D Printing?

Zircon sand has potential applications across a wide range of industries, each benefiting from unique properties this material offers. In the aerospace sector, for instance, the demand for lightweight materials without compromising strength makes zircon a compelling choice for structural components. The material’s ability to maintain integrity under high temperatures is crucial for aerospace applications, where components must withstand extreme environmental conditions, including pressure and heat during flight.

Similarly, the automotive industry is increasingly leaning towards zircon for producing parts that require both durability and heat resistance. Engine components that undergo extreme conditions, such as braking systems made of zircon, can significantly enhance vehicle safety and performance. Moreover, with the growing trend toward electric and hybrid vehicles, the demand for high-performance materials is likely to increase, further solidifying zircon’s role in the automotive supply chain.

Medical device production is another promising area, where precision and reliability are paramount. Products that require stringent performance metrics can leverage zircon’s qualities. For example, surgical instruments and orthopedic implants made from zircon demonstrate not only high strength but also improved resistance to corrosion and wear, extending their usability and enhancing patient safety.

Other sectors showing rising interest include:

- Construction: Zircon’s exceptional heat resistance allows its use in fireproof materials, making it suitable for building components that need to withstand extreme temperatures.

- Jewelry Design: The aesthetic appeal and durability of zircon make it a preferred choice for intricate, high-quality jewelry pieces, attracting consumers looking for both beauty and longevity.

- Electronics: The electronic components market can benefit as zircon’s properties allow for better insulation and thermal stability, crucial for high-performance devices.

Overall, the versatility of zircon sand across various applications not only showcases its unique characteristics but also underscores its potential to revolutionize multiple industries reliant on advanced materials for high-quality production.

What Innovations Are Emerging in Zircon Sand 3D Printing?

The field of 3D printing is dynamic, with continuous technological advancements driving innovation. Emerging innovations involving zircon sand hold much promise for various applications. Recent advances include improved printing techniques that enhance effectiveness while reducing waste. Many businesses are now employing processes that allow for more consistent layering, which can produce items that require less finishing.

For instance, companies are exploring the development of hybrid materials that combine zircon with polymers. This approach aims to leverage the benefits of both materials, creating products with enhanced mechanical properties and aesthetic appeal. The possibilities of combining materials effectively can revolutionize product design, leading to less material waste and improved functionality.

Moreover, case studies from innovative companies illustrate the successful integration of zircon into their processes, resulting in notable improvements in efficiency. A clear example includes a manufacturer who reduced their overall production time by optimizing 3D printing parameters conducive to working with zircon sand.

Innovative software solutions are also being designed to simulate material behavior during design and production phases, reducing the number of failed prints and optimizing the use of zircon.

How Can Companies Overcome Challenges with Zircon Sand?

To navigate the challenges associated with zircon sand, companies can adopt several strategic approaches. For sourcing issues, establishing long-term relationships with reliable suppliers can mitigate risks significantly. Building partnerships with multiple suppliers can also ensure consistent availability amid market fluctuations. This practice is like having a safety net for critical materials.

In terms of processing difficulties, investing in ongoing employee training proves invaluable. A well-informed workforce familiar with the unique properties of zircon sand can handle it more effectively, leading to fewer mistakes and higher quality outputs. This not only enhances efficiency but also fosters a culture of continuous improvement and innovation within the organization.

Sustainability initiatives should be a priority, as companies committing to responsible mining practices can enhance their reputations and reduce environmental impacts. This approach can create positive customer relationships, especially among eco-conscious clients who prefer to support businesses that align with their values.

Table: Strategies for Handling Zircon Sand Challenges

| Challenge | Strategy |

|---|---|

| Sourcing Issues | Build relationships with suppliers |

| Processing Difficulties | Train employees on handling |

| Environmental Concerns | Adopt sustainable practices |

What Regulatory Considerations Affect Zircon Sand Use?

Utilizing zircon sand in 3D printing isn’t just about performance; regulatory considerations are crucial as well. Many countries set material safety standards to ensure products are safe for consumers. Understanding these regulations is vital for compliance, as violating them could lead to significant penalties.

Environmental regulations are also significant. Companies must adhere to laws governing mining practices and emissions resulting from production processes. Meeting these standards not only helps with legal compliance but also strengthens a company’s brand image as a responsible organization.

Additionally, manufacturers should stay informed of any changes in regulations. Engaging with industry groups, trade associations, and attending relevant conferences can provide valuable insights. Building relationships with regulatory bodies can also facilitate smoother operations and clearer communication when new standards arise.

How Can Businesses Stay Ahead in Zircon Sand 3D Printing?

Staying competitive in this field involves strategic approaches that adapt to ever-evolving technology. Conducting market research can reveal trends and opportunities in the use of zircon in 3D printing. For instance, analyzing data from market reports might uncover new niches or applications that others have overlooked.

Networking events are another excellent way to stay ahead. Building connections with other professionals expands the scope for collaboration and shared knowledge, which often leads to innovative solutions. Fortifying relationships with researchers, suppliers, and industry practitioners could help stay at the forefront of innovations and shifts in the market.

Lastly, a commitment to continuous learning is essential. Staff should be encouraged to participate in workshops, courses, or industry conferences. This investment in skill development prepares companies to tackle any advancements in technology or materials. To add depth, consider these growth opportunities:

- Webinars: Join relevant virtual sessions to learn from industry experts.

- Industry Conferences: Participate in exhibitions and networking opportunities.

- Certification Courses: Encourage team members to gain certifications related to 3D printing technologies.

What Future Trends Should We Anticipate for Zircon Sand?

As industries evolve, anticipating trends in zircon’s usage is pivotal. Market growth is expected as more companies recognize its benefits. For example, analysts predict a significant uptick in demand for durable materials, which zircon meets. The trend toward lightweight and heat-resistant materials can further accelerate the adoption of zircon in various applications.

Additionally, anticipating changes in consumer preferences could shape the adoption rate. As sustainability becomes a primary consideration, solutions that focus on recycled materials or eco-friendly processes may become more prominent.

New applications are also on the horizon as more research is conducted. Industries might explore zircon’s capabilities beyond traditional uses, leading to innovative projects and products that were once thought impossible. Businesses ready to adapt and embrace these trends will be well-positioned to thrive in an increasingly competitive landscape.

Conclusion

In summary, zircon sand presents significant advantages for 3D printing, including durability, surface quality, and heat resistance that meet the demanding standards of various industries. As companies effectively integrate this mineral, they can achieve notable improvements in efficiency and product quality, navigating the challenges that accompany its use. At Global Industry, we are committed to providing the latest insights and resources to support your journey in harnessing the potential of zircon sand in your 3D printing applications. For further valuable information on material choices, we invite you to visit our website and discover how we can work together to enhance your business operations.

FAQ Section

Q1: What advantages does zircon sand offer for 3D printing?

Zircon sand brings numerous benefits to 3D printing, including enhanced durability, which allows products to withstand wear and tear over time. Additionally, it provides an improved surface finish, giving printed items a professional look and feel. Its excellent heat resistance enables the production of parts that can handle high temperatures without deforming, making it suitable for demanding applications in various industries.

Q2: How does zircon sand processing differ from other materials?

The processing of zircon sand involves a series of specialized steps that differ from other commonly used materials. Unlike simple plastic filaments, zircon must be mined and refined to eliminate impurities that could affect quality. This refinement process typically includes dry and wet separation methods to ensure a high degree of purity, which is crucial for successful 3D printing and optimal mechanical properties.

Q3: What are the main challenges in using zircon sand for 3D printing?

Key challenges associated with zircon sand include sourcing consistency due to its geographical concentration in mining regions, which can lead to supply chain disruptions. Additionally, the material requires specific handling and machine adjustments for effective 3D printing, which may necessitate investments in new equipment or training for staff. Furthermore, environmental considerations related to zircon extraction can pose regulatory hurdles for companies focused on sustainability.

Q4: Which industries are leveraging zircon sand in their 3D printing processes?

Zircon sand is increasingly finding its way into several industries, most notably aerospace, where the need for lightweight yet strong materials is paramount. The automotive sector also benefits, particularly in producing durable engine components. Medical device manufacturing has also begun to explore the advantages of zircon, especially for precision instruments. Additionally, construction and jewelry design sectors are actively discovering its potential for unique applications.

Q5: How can businesses effectively manage zircon sand challenges?

To navigate the challenges posed by zircon sand, businesses should establish strong relationships with reliable suppliers to ensure consistent material availability. Investing in employee training is vital, as a well-trained workforce can optimize the material’s use and minimize processing errors. Companies should also consider adopting sustainable practices to address environmental concerns and enhance their reputations, which can improve customer relationships and open up new market opportunities.