The role of zirconium silicate in sustainable battery technologies is becoming increasingly significant as industries strive for environmentally friendly solutions. As electric vehicles and renewable energy sources gain traction, manufacturers face the challenge of balancing high performance with ecological responsibility. This mineral offers a unique combination of properties that enhances battery efficiency while minimizing environmental impact. It is essential for decision-makers and stakeholders to understand how incorporating zirconium silicate can lead to innovative approaches that not only improve battery technology but also align with global sustainability goals. This article delves into these insights, highlighting the material’s potential to revolutionize energy storage solutions across various sectors.

What is Zirconium Silicate and Its Properties?

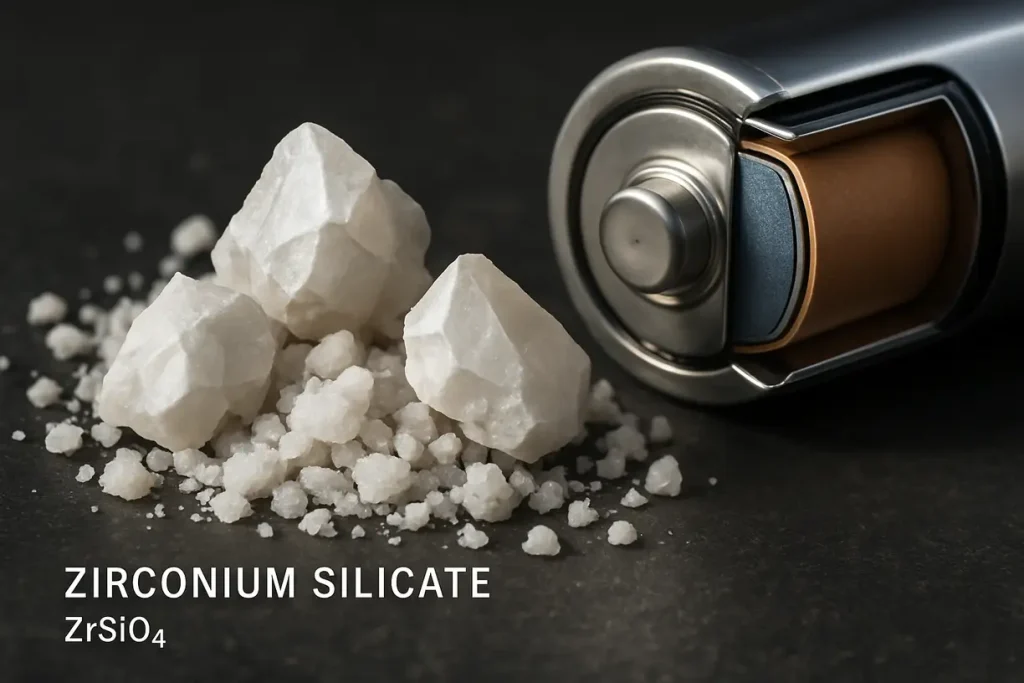

Zirconium silicate is a mineral composed of zirconium, silicon, and oxygen. It appears in various forms and is recognized for its thermal stability and chemical resistance. These properties make it a desirable component in numerous applications, including ceramics, glass, and electronics.

But what sets zirconium silicate apart from other materials? Its unique properties include high melting points and exceptional durability. These features allow it to withstand extreme conditions, making it suitable for battery technology. Additionally, it is non-toxic and environmentally benign, which speaks to its sustainability credentials.

When professionals consider materials for battery production, zirconium silicate offers versatility. It can be used in different battery types, such as lithium-ion and solid-state batteries, thus serving multiple sectors. Its compatibility with various manufacturing processes contributes to its rising popularity in innovative energy storage solutions.

Key Properties of Zirconium Silicate:

| Property | Description |

|---|---|

| Thermal Stability | Withstands high temperatures without decomposition |

| Chemical Resistance | Resistant to acids and bases |

| Non-Toxic | Safe for the environment and human health |

| Versatile Applications | Used in batteries, ceramics, and electronics |

This image illustrates the crystalline structure of zirconium silicate, highlighting its stability and potential use in batteries.

Understanding the basic properties of zirconium silicate is crucial for grasping its potential in battery technology. As industries look for sustainable options, this material presents an attractive solution that balances functionality with environmental responsibility.

Why Focus on Sustainable Battery Technologies?

Sustainability in battery technology is crucial in our world increasingly affected by climate change. Why should coSustainability in battery technology is crucial in our world increasingly affected by climate change. Why should companies prioritize sustainability? As the demand for electric vehicles and renewable energy sources surges, the need for more environmentally friendly battery solutions becomes paramount. Conventional battery production often employs harmful materials and processes that contribute to pollution, resource depletion, and ecological harm.

The necessity for compliance with environmental regulations is rising. Companies face mounting pressure from regulators and consumers alike to adopt sustainable practices. Stricter laws regarding environmental impact compel organizations to innovate in their battery technologies. This focus not only benefits the environment but can also lead to significant cost savings over time. By reducing waste and minimizing energy consumption, firms can enhance their bottom line while doing right by the planet.

Furthermore, integrating sustainable practices into battery technology can enhance brand reputation and market appeal. Corporations recognized for their commitment to environmental stewardship often attract a more conscientious consumer base that values sustainability. By prioritizing eco-friendly practices, companies can not only comply with regulations but also differentiate themselves in the crowded market, potentially leading to increased customer loyalty.

Benefits of Sustainable Battery Technologies:

- Reduced environmental impact and pollution

- Enhanced company reputation and consumer trust

- Compliance with evolving regulations

- Cost savings through efficient resource management

- Increased market competitiveness

In summary, embracing sustainable practices in battery technologies is essential for both regulatory compliance and competitiveness. The shift toward greener solutions is not just a passing trend; it represents a fundamental change requiring urgent attention from decision-makers across industries. As businesses strive to meet the demands of a dynamic marketplace, focusing on sustainable solutions will be pivotal for long-term success and environmental responsibility.

How Does Zirconium Silicate Fit into Battery Design?

When looking at modern battery designs, zirconium silicate plays an essential role. How does it integrate into battery construction? It is often used in the anode and electrolyte layers, where its unique properties significantly enhance the overall performance and efficiency of batteries.

This mineral improves battery efficiency by ensuring chemical stability and promoting faster ion transport within the cells. Quicker ionic movement is crucial in reducing charging and discharging times, which is particularly attractive for applications in electric vehicles and portable electronics. Additionally, it helps maintain optimal battery temperature during operation, thereby reducing the risk of overheating that can lead to safety hazards.

Several successful projects highlight the effectiveness of zirconium silicate. For instance, development teams are investigating the application of zirconium silicate in solid-state batteries, where it functions as a solid electrolyte. These next-generation batteries promise greater energy density and improved safety compared to traditional liquid electrolyte systems. The ability to enhance energy density not only translates to longer-lasting batteries but also allows for lighter and smaller designs, which are particularly important in consumer electronics and electric vehicles.

Examples of Battery Designs Incorporating Zirconium Silicate:

| Battery Type | Application | Key Advantages |

|---|---|---|

| Lithium-Ion | Electric vehicles | Fast charging, high energy density |

| Solid-State | Consumer electronics | Improved safety and performance |

| Sodium-Ion | Large-scale grid storage | Cost-effective and sustainable |

Importantly, the adaptability of this mineral enables its incorporation into various battery chemistries, from lithium-ion to sodium-ion systems. This versatility allows engineers and researchers to explore new combinations and formulations that enhance performance metrics and sustainability.

In summary, zirconium silicate is integral to modern battery design. Its unique properties facilitate innovative solutions, improving energy storage systems and addressing the growing demands for efficiency and safety in the energy sector.

What are the Benefits of Using Zirconium Silicate in Batteries?

The incorporation of this mineral in batteries presents several compelling advantages. What are these benefits? First and foremost, it enhances overall battery performance. By enabling quicker charging and increased energy density, zirconium silicate ensures that batteries meet the growing demands for energy efficiency. This is particularly beneficial in modern applications, where consumers expect not only faster charging times but also higher storage capabilities for longer usage periods.

Another significant benefit is the reduction of thermal runaway risk. Batteries made with this mineral are less likely to overheat, minimizing safety hazards. This property is especially vital in applications such as electric vehicles, where battery safety is paramount. With the increasing importance of safety in technology, the use of zirconium silicate contributes to a more stable performance, thus gaining consumer trust.

Cost-effectiveness is also a noteworthy benefit. While some advanced materials can be expensive, it is relatively affordable to source and process. This affordability can lower production costs, making sustainable battery solutions more accessible to a wider range of manufacturers. Furthermore, the reduced overall maintenance costs, owing to its durability, make it a financially attractive option for long-term investments in battery technologies.

Key Benefits of Zirconium Silicate in Battery Technology:

| Benefit | Description |

|---|---|

| Enhanced Performance | Faster charging and higher energy density |

| Improved Safety | Lower risk of thermal runaway |

| Cost-Effective | Affordable to source and process |

| Eco-Friendly | Safe for the environment |

Finally, zirconium silicate is eco-friendly. Its properties ensure that it does not release harmful substances during use or disposal. Thus, it aligns perfectly with the industry’s shift toward greener alternatives, providing a holistic solution for battery manufacturers looking to enhance their sustainability credentials.

In conclusion, the use of this mineral in batteries offers multiple advantages, from improved performance and safety to cost efficiency and environmental benefits. These factors make it an attractive option for companies seeking to innovate sustainably while meeting the evolving needs of their consumers.

How is Zirconium Silicate Processed for Battery Use?

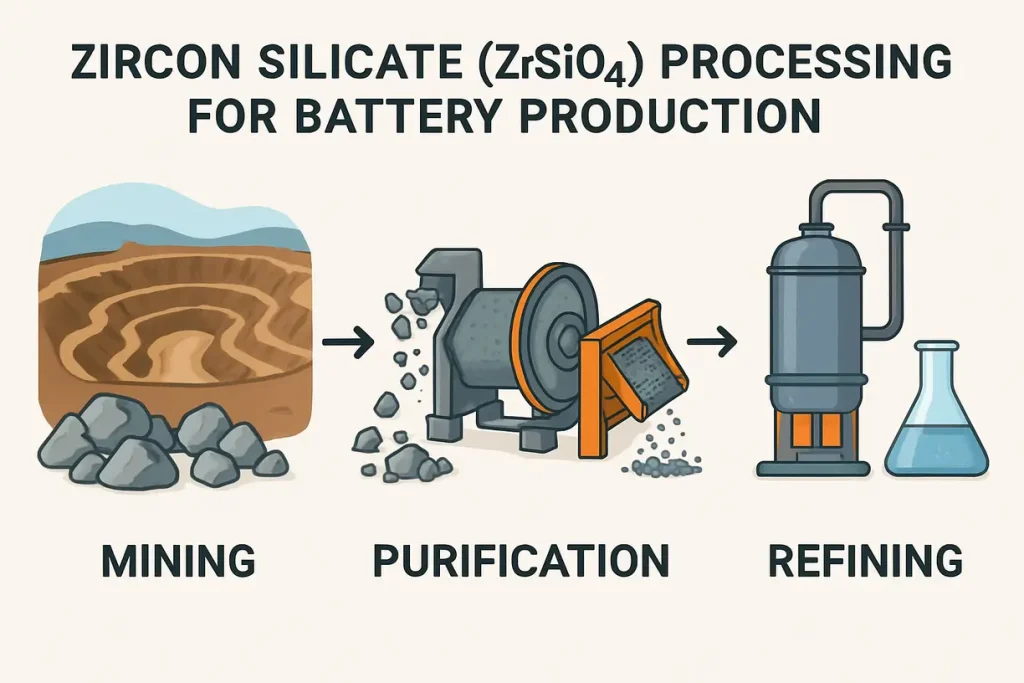

Processing zirconium silicate for battery applications requires careful attention to detail. What does this processing involve? The first step usually involves mining the raw mineral, which can be done through traditional or modern techniques. Once extracted, the material undergoes purification to remove impurities.

Once extracted, the mineral undergoes purification to remove impurities and improve its performance characteristics. This step is crucial, as contaminants can significantly affect the efficiency and safety of the final battery product. Various techniques, including chemical treatments and physical separation processes, are utilized to ensure high material quality.

After purification, zirconium silicate is refined into the desired particle size and form, with considerations for specific battery applications. Achieving the appropriate particle size is critical since it influences the material’s performance in batteries. During this phase, advanced techniques such as milling and granulation may be employed to tailor the material’s properties to meet different requirements.

Eco-friendly processing methods are gaining traction, driven by the industry’s commitment to sustainability. For instance, some companies are exploring water-based processes and low-energy treatments to reduce harmful emissions during production. These innovations not only minimize environmental impacts but also align with the global shift towards greener manufacturing practices.

Processing Steps for Zirconium Silicate:

- Mining: Extracting raw zirconium silicate from mineral deposits.

- Purification: Removing impurities to ensure high material quality.

- Refinement: Adjusting particle size through milling.

- Formulation: Preparing the material for specific battery applications.

This image depicts the processing steps of zirconium silicate, showcasing mining, purification, and refinement for battery production.

Protecting the environment during processing is essential. Implementing recycling methods helps minimize waste and promotes resource efficiency. Companies focusing on sustainable practices can benefit in the long run by fostering a more responsible production chain.

In conclusion, the processing of zirconium silicate involves a series of meticulous steps aimed at maintaining both quality and sustainability. These carefully managed processes ultimately determine how well this material performs in various battery applications, underscoring its importance in the industry.

What Challenges Exist in Implementing Zirconium Silicate?

Despite its potential, using zirconium silicate in battery technology is not without challenges. What obstacles must be addressed? One significant hurdle is the technical limitations of integrating this material into existing battery systems. For example, the appropriate dosages and methods of incorporation can vary greatly depending on the specific application.

Market barriers also exist. While zirconium silicate is affordable, the cost of research and development for new battery formulations can be high. Companies may hesitate to invest in these technologies without guaranteed returns.

Moreover, the ongoing challenge of scalability must be considered. While promising laboratory results may not easily transition to large-scale production. Adapting processes for mass manufacturing can require additional resources and time.

Research gaps remain in understanding the long-term performance of batteries utilizing zirconium silicate. Studies that investigate the consequences of extended use and environmental factors are essential to ensure reliability.

Challenges in the Implementation of Zirconium Silicate:

- Technical constraints related to battery design and requirements

- High research and development costs

- Difficulty in scaling from lab to production

- Limited knowledge around long-term performance and wear

In summary, implementing zirconium silicate in battery technologies brings various challenges, from technical limitations to market barriers. Addressing these issues is vital to unlocking its potential.

How Does Zirconium Silicate Contribute to Battery Safety?

Safety is a paramount concern in battery technology, especially in high-demand applications. How does zirconium silicate enhance battery safety? Its thermal properties play a critical role in preventing overheating. Batteries that use this material are less likely to experience thermal runaway, a serious issue in conventional lithium-ion batteries.

The chemical stability of zirconium silicate also reduces the risk of internal short-circuiting, which can lead to fires or battery failure. Better structural integrity supports safer operation in various environments, ensuring that batteries perform reliably under stress.

Regular safety testing is essential. Companies using this mineral should adopt rigorous testing protocols to monitor performance over time. By doing so, firms can better understand the material’s behavior in real-world applications and enhance safety measures.

Safety Benefits of Using Zirconium Silicate:

| Safety Aspect | Contribution |

|---|---|

| Thermal Management | Reduces overheating issues |

| Structural Integrity | Lowers risks of battery failure |

| Burn Rate | Minimal flammability |

| Performance Under Stress | Maintains reliability in diverse conditions |

Ultimately, the contribution of zirconium silicate to battery safety makes it a valuable asset in energy storage technologies. Its properties help mitigate risks, ensuring peace of mind for manufacturers and consumers alike.

What Future Trends Can Be Expected for Zirconium Silicate in Batteries?

Looking ahead, several trends are emerging related to zirconium silicate and battery technologies. What can we expect? First, ongoing research will likely lead to innovations in battery chemistry. Companies are continuously seeking ways to improve performance metrics and energy density, making this mineral a key player in these developments.

Collaboration among industries is another trend to watch. As companies unite to tackle the sustainability challenge, partnerships could yield groundbreaking advancements. Academic institutions, startups, and established firms may collaborate on projects that focus on integrating zirconium silicate into novel battery solutions.

Moreover, the demand for electric vehicles is expected to rise. This could drive further exploration into more efficient, safer, and greener battery applications incorporating zirconium silicate.

Emerging Trends in Battery Technology:

- Increased focus on solid-state batteries

- Enhanced collaboration between research and industry

- Rising demand for electric vehicles and renewable energy solutions

- Development of recycling methods for battery materials

The need for recycling and reusing battery materials is also gaining ground. As the focus on circular economy practices grows, sustainable materials like zirconium silicate will likely become increasingly valuable.

In summary, the future of zirconium silicate in batteries looks promising. Innovations, collaborations, and a greater emphasis on sustainability will shape the course of battery technology.

Conclusion

In conclusion, zirconium silicate is quickly emerging as a crucial material in the advancement of sustainable battery solutions. Its unique properties not only enhance battery performance but also contribute to environmental sustainability—a critical factor as industries strive to meet growing energy demands while minimizing ecological impacts. By integrating this mineral into battery technologies, companies can enjoy significant benefits, including improved efficiency, safety, and longevity.

The shift towards greener battery solutions represents not only an opportunity for innovation but also a pathway to establishing a more responsible and eco-conscious market. Embracing such materials can lead to long-term savings, improved operational effectiveness, and a stronger brand reputation in an increasingly competitive landscape.

As organizations continue to adapt to changing consumer preferences and stricter regulations, leveraging eco-friendly materials will be essential. The future of energy storage promises to be more efficient and sustainable, and those who prioritize materials that align with these values will be better positioned for success in the evolving marketplace. Therefore, companies have a unique opportunity to lead the charge towards a sustainable energy future by adopting innovative approaches in battery technology.

FAQ Section

Q1: What makes zirconium silicate a sustainable choice for batteries?

Zirconium silicate is considered sustainable due to its non-toxic nature and minimal environmental impact during production. It promotes greener battery technologies by reducing dependency on hazardous materials commonly used in traditional battery manufacturing. Its thermal stability also contributes to increased safety and longevity, further enhancing the sustainability of battery solutions.

Q2: How does the use of zirconium silicate impact battery lifespan?

Integrating zirconium silicate in batteries enhances their durability and structural integrity. This material helps to improve thermal management and chemical stability, reducing wear and tear over time. As a result, batteries containing zirconium silicate are likely to exhibit a longer lifespan, providing end-users with greater value and reliability.

Q3: Are there significant cost differences when using zirconium silicate?

While the initial costs for materials may vary, incorporating zirconium silicate often leads to significant long-term savings. Its efficiency in improving battery performance can lower operational costs, such as energy consumption during charging. Thus, any upfront investment is typically offset by the enhanced performance and durability offered by this innovative material.

Q4: What research is being conducted on zirconium silicate in batteries?

Current research focuses on optimizing the properties of zirconium silicate for various battery applications. Scientists are exploring its behavior as a solid electrolyte, enhancing charge-discharge rates and energy density. Additionally, studies aim to better understand its long-term stability and performance under different environmental conditions to ensure safe and efficient use in next-generation batteries.

Q5: How does zirconium silicate compare to other materials in battery technology?

Compared to traditional battery materials, zirconium silicate offers several unique advantages. Its ability to withstand high temperatures and resist chemical degradation makes it a superior choice for safety-critical applications. Additionally, its environmentally friendly profile positions it as a more attractive option in an industry increasingly focused on sustainable practices.