In the ever-evolving electronics industry, manufacturers face challenges in material selection for optimal performance. Zirconium silicate stands out as an appealing option, but many may still question its advantages in practical applications. This article aims to clarify the benefits of this versatile material, showcasing its role in enhancing product quality and safety. Offering trustworthy insights, this article will help decision-makers understand how zirconium silicate can support their manufacturing goals and address common industry concerns effectively.

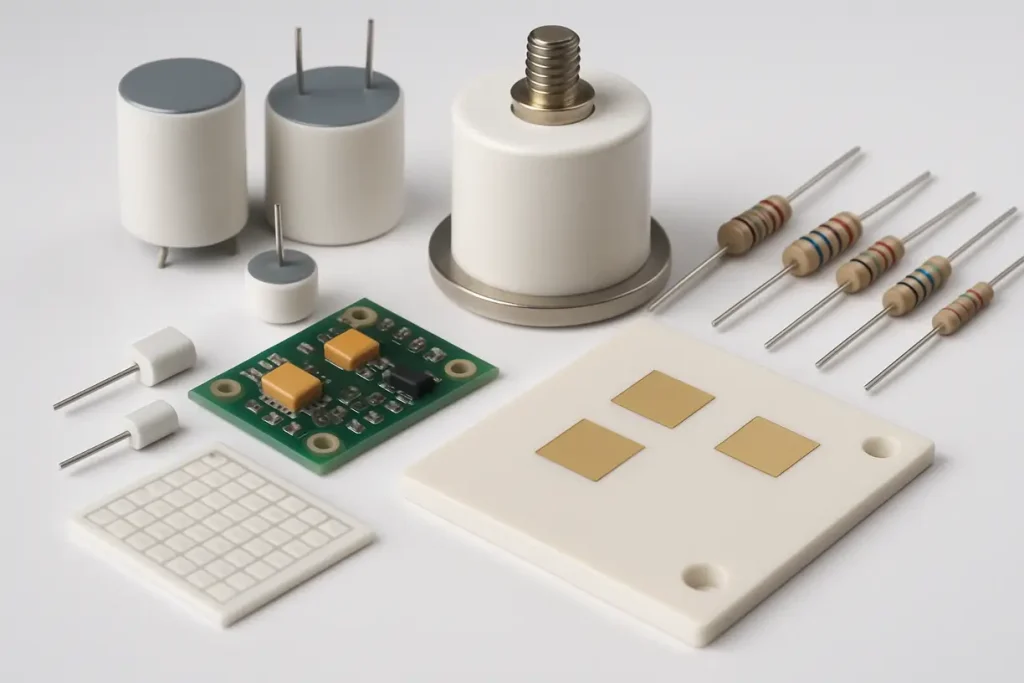

This image illustrates various electronic components that utilize zirconium silicate as an insulating material, highlighting its importance in the industry.

What Role Does Zirconium Silicate Play in Electronics?

Zirconium silicate is essential in the electronics sector due to its unique properties. It is a stable, inorganic compound utilized primarily as an insulating material. Its significant resistance to heat makes it suitable for high-temperature applications. This reliability is crucial, especially in devices where heat can affect performance.

Compared to other insulating materials, zirconium silicate offers superior thermal and electrical insulation. It helps to minimize energy loss in electronic components, which is vital for efficient device functioning. Factors such as heat dissipation, insulation breakdown, and operational efficiency all play a part in its effectiveness.

Consequently, manufacturers often prefer this material for various applications ranging from power electronics to consumer gadgets.

When evaluating material options, manufacturers must assess the trade-offs between performance, cost, and safety. Key points to consider include:

- Thermal resistance: Critical for preventing heat-related failures.

- Electrical insulation: Ensures safe operation and energy efficiency.

- Chemical inertness: Maintains product integrity over time.

- Mechanical stability: Supports longevity under various conditions.

This compound effectively balances these factors, making it a favorable choice. With its chemically inert nature, it poses minimal risks to both the environment and human health, further enhancing its appeal in the industry.

In summary, zirconium silicate plays a crucial role in electronics by providing thermal stability, electrical insulation, and safety, setting it apart from other materials in the market.

How Does Zirconium Silicate Enhance Performance?

One of the key benefits of zirconium silicate is its ability to enhance the performance of electronic components. This material exhibits exceptional thermal stability, allowing devices to operate efficiently under high temperatures without degrading.

It is favored for its high electrical insulation properties, ensuring minimal energy loss and contributing to energy-efficient designs. This is particularly important for manufacturers aiming to meet growing energy efficiency standards.

Moreover, zirconium silicate’s mechanical strength adds another layer of reliability. It can withstand physical stresses and strains that electronic devices may encounter during use. This resilience is important in ensuring longevity and reducing maintenance costs over time.

Additionally, its low thermal expansion coefficient means it maintains stability even in fluctuating temperatures. Such stability ensures consistent performance, avoiding circuit failures or malfunctions due to heat-induced stresses.

Key aspects of performance enhancement include:

- High thermal conductivity: Allows for better heat management in devices.

- Low dielectric loss: Minimizes energy waste during operation.

- Resistance to thermal shock: Ensures reliability during rapid temperature changes.

In conclusion, zirconium silicate significantly enhances the performance of electronic components through its thermal stability, electrical insulation, and mechanical strength. These attributes promote energy efficiency and durability, key factors for any electronics manufacturer.

This image shows the crystalline structure of zirconium silicate, emphasizing its thermal stability and chemical resilience for electronic applications.

What Are the Cost Benefits of Using Zirconium Silicate?

In today’s competitive landscape, cost management is crucial for manufacturers. Using zirconium silicate can lead to significant cost benefits over time. Its durability reduces maintenance and replacement expenses, allowing companies to allocate resources more efficiently.

When comparing this material to alternatives, the initial investment may appear higher; however, its longer lifespan and robustness often translate to reduced operational costs. Devices incorporating zirconium silicate typically require fewer repairs and replacements.

Companies can track cost advantages through:

- Lower maintenance frequency: Directly linked to reduced operational downtime.

- Extended product lifespan: Leads to savings on raw materials and production costs.

- Energy savings: Due to enhanced performance, especially in high-demand applications.

Another cost advantage is its thermal efficiency. By enhancing energy performance, zirconium silicate can lower energy bills. This benefit also aligns with sustainability goals, as using energy-efficient materials contributes to lower emissions.

A demonstration of these savings can be seen in the semiconductor industry, where businesses have reported up to 25% savings on energy costs after integrating this material into their processes.

To sum up, the cost benefits of using zirconium silicate are substantial. While initial costs might be higher, the long-term savings and efficiencies make it a wise investment for manufacturers.

How Is Zirconium Silicate Used in Industry Applications?

Zirconium silicate has a diverse range of applications in the electronics industry. One of its primary uses is in semiconductors, where it serves as a dielectric material, crucial for miniaturizing components while maintaining performance.

In capacitors, it enhances energy storage capabilities, improving the responsiveness of devices reliant on rapid energy release. Likewise, it is imperative in resistors, where stability amidst temperature fluctuations is a critical factor for performance.

Another essential application is in display technologies. Devices such as LCDs and LEDs benefit from the material’s insulating properties, which contribute to better brightness and image quality.

| Application | Function | Benefits |

|---|---|---|

| Semiconductors | Dielectric material | Enhances miniaturization and performance |

| Capacitors | Energy storage | Improves efficiency and responsiveness |

| Resistors | Temperature stability | Maintains performance during temperature changes |

| Display technologies | Insulating layer for devices | Achieves better brightness and image quality |

In summary, zirconium silicate is integral to various industry applications. Its versatility enhances performance in semiconductors, capacitors, resistors, and display technologies, making it a valuable material in electronics.

What Are the Key Properties of Zirconium Silicate?

Zirconium silicate possesses several key properties that make it suitable for electronic applications. Its chemical composition is primarily made up of zirconium dioxide and silica, which contributes to its unique characteristics.

One of the standout properties is its chemical inertness. This feature makes it resistant to corrosive environments and ensures that it does not react adversely with other materials, thereby maintaining product integrity.

Another important property is its mechanical strength. Zirconium silicate can endure significant stress and pressure. This durability is essential in electronics manufacturing, where components often face rigorous conditions.

Moreover, this material is environmentally friendly. Its extraction and processing have a smaller ecological footprint compared to many synthetic materials, which is increasingly important for manufacturers committed to sustainable practices.

| Property | Description | Importance in Electronics |

|---|---|---|

| Chemical Inertness | Resistant to reactions with other materials | Maintains product integrity |

| Mechanical Strength | High resistance to stress | Ensures durability and longevity |

| Environmental Impact | Lower ecological footprint | Supports sustainable manufacturing practices |

Additional Key Properties:

- High melting point: Suitable for high-temperature applications.

- Excellent thermal shock resistance: Helps prevent damage in rapidly changing environments.

- Non-toxic characteristics: Ensures safe handling and use in consumer products.

In essence, the key properties of zirconium silicate—chemical inertness, mechanical strength, and environmental friendliness—solidify its role as a favorable material in electronics.

How Does Zirconium Silicate Contribute to Product Safety?

Safety is a paramount concern for manufacturers in any industry, especially electronics. This compound contributes significantly to the safety of electronic products. Its high thermal stability minimizes risks associated with overheating, which can lead to fires or device failures.

Moreover, materials play a critical role in compliance with safety standards. Zirconium silicate meets stringent safety regulations, reducing liability concerns for manufacturers. Ensuring materials can withstand high temperatures and pressure contributes to their overall safety profile.

Another aspect is its low toxicity. Unlike some materials used in electronics, zirconium silicate does not release harmful substances into the environment or pose health risks to humans. This characteristic is particularly important as companies navigate increasing consumer demand for safe and sustainable products.

| Safety Aspect | Benefit | Impact on Product Development |

|---|---|---|

| Thermal Stability | Reduces overheating risks | Enhances overall product safety |

| Compliance | Meets safety regulations | Lowers liability for manufacturers |

| Low Toxicity | Non-harmful to humans and environment | Aligns with consumer demand for safety |

In summary, zirconium silicate enhances product safety through its thermal stability, compliance with safety standards, and non-toxic nature. This makes it a trusted choice for manufacturers prioritizing safety.

This image depicts a variety of electronic devices that utilize zirconium silicate, showcasing its role in ensuring product safety and performance.

What Innovations Are Emerging with Zirconium Silicate?

Innovation is crucial in the fast-paced electronics market, and zirconium silicate continues to inspire new applications. Currently, research is focusing on cutting-edge uses for this material, particularly in advanced electronics like flexible circuits and wearable technology.

As devices become more compact, the demand for materials that can deliver both performance and flexibility increases. Zirconium silicate has the potential to meet these needs, with ongoing studies exploring its adaptability in these new environments.

Future trends may also see an increase in its use within eco-friendly products. Manufacturers are eager to utilize sustainable materials that reduce their carbon footprint. Research is actively being conducted to maximize the potential of this compound in green technology.

| Innovation | Description | Potential Impact |

|---|---|---|

| Flexible Circuits | Adaptability to new designs | Enhances flexibility and performance |

| Wearable Technology | Incorporation in compact devices | Supports growth in consumer electronics |

| Eco-Friendly Applications | Development of sustainable products | Reduces environmental impact |

In conclusion, emerging innovations with zirconium silicate promise to expand its applications further. With ongoing research, this material is poised to transform the electronics industry by meeting future demands.

How Does Zirconium Silicate Compare to Other Materials?

When considering material options for electronics, comparing zirconium silicate to alternatives is essential. Materials like aluminum oxide and silica are common competitors. Each has unique properties, but zirconium silicate often secures a competitive edge.

For instance, compared to aluminum oxide, zirconium silicate offers better thermal insulation while maintaining a lightweight structure. Such properties make it preferable for high-performance applications.

On the other hand, silica, while abundant and low-cost, lacks the mechanical strength and thermal stability that zirconium silicate provides. Manufacturers looking for longevity and reliability often favor this compound over alternatives.

Additional Points of Comparison:

- Cost-effectiveness: Long-term savings outweigh initial expenditures for zirconium silicate.

- Availability: Sourcing may be easier for one material over others based on regional suppliers.

- Processing requirements: Consideration of how different materials behave during manufacturing.

| Material | Thermal Insulation | Mechanical Strength | Cost Effectiveness |

|---|---|---|---|

| Zirconium Silicate | High | High | Moderate |

| Aluminum Oxide | Moderate | High | Moderate |

| Silica | Low | Low | Low |

In essence, zirconium silicate’s advantages over other materials position it as a strong choice for electronics manufacturing. Its superior thermal insulation and mechanical strength make it the preferred option in many applications.

What Should Manufacturers Consider When Choosing Zirconium Silicate?

For manufacturers considering this compound, there are several key factors to evaluate. First and foremost is the quality of the material. Sourcing from reputable suppliers guarantees purity and reliability.

Next, manufacturers should assess application-specific requirements. Different electronic devices may necessitate varying grades or formulations of zirconium silicate. Understanding these needs will enhance product performance and ensure compatibility.

Lastly, companies should consider total lifecycle costs. While zirconium silicate might entail higher upfront costs, evaluating long-term savings through durability and performance will provide a clearer picture of its value.

Other Considerations Include:

- Supplier credibility: Importance of working with reliable manufacturers and suppliers for consistent quality.

- Testing requirements: Conducting proper material testing to guarantee suitability for specific applications.

- Regulatory compliance: Ensuring the material meets all industry standards and regulations.

In summary, manufacturers should focus on quality, specific application needs, and total lifecycle costs when integrating zirconium silicate into their processes. These considerations ensure the material’s effectiveness in enhancing product performance.

What Are Common Misconceptions about Zirconium Silicate?

Despite the advantages of zirconium silicate, several misconceptions persist in the industry. One common belief is that it is too expensive for practical use. While the upfront costs may be higher, the long-term benefits often outweigh these initial investments.

Another misconception is that this material isn’t versatile. In truth, its applications span a range of electronics, from semiconductors to consumer appliances. Its multifunctionality is one of its most significant advantages.

Lastly, some may question its environmental impact. However, zirconium silicate’s low toxicity and eco-friendly properties make it safer than many other synthetic materials.

| Misconception | Reality | Implications for Manufacturers |

|---|---|---|

| Too Expensive | Initial costs are higher, but savings follow | Encourages long-term investment |

| Not Versatile | Wide range of applications | Increases potential uses |

| Poor Environmental Impact | Low toxicity and eco-friendly | Aligned with sustainability goals |

In essence, addressing these misconceptions can help manufacturers see the true value of zirconium silicate. Understanding its benefits can lead to more informed decision-making regarding material selection.

Conclusion

In summary, zirconium silicate offers numerous benefits for electronics manufacturers, making it a valuable asset in modern production processes. Its unique properties enhance performance and contribute to product safety while providing cost advantages essential in today’s competitive landscape. By improving energy efficiency and reducing maintenance requirements, this material allows companies to allocate resources more effectively.

Moreover, as the demand for innovative and sustainable solutions continues to grow, the potential for this compound to support eco-friendly manufacturing practices cannot be overlooked. As such, integrating zirconium silicate into your production processes not only aligns with industry standards but can also position your company favorably in the marketplace.

At Global Industry, we encourage manufacturers to explore the advantages of this material further. By leveraging its attributes, companies can elevate their production capabilities and meet the evolving needs of consumers while staying ahead in a rapidly changing industry.

FAQ Section

Q1: What specific advantages does zirconium silicate provide?

Zirconium silicate offers several key benefits that make it highly suitable for electronic applications. Its high thermal stability allows electronic devices to function efficiently at elevated temperatures, reducing the risk of overheating. Additionally, this material provides excellent electrical insulation, minimizing energy loss and enhancing overall device performance. Its chemical inertness ensures compatibility with various other materials, contributing to the long-term durability of electronic components.

Q2: How does zirconium silicate affect manufacturing costs?

While the initial investment in zirconium silicate may be higher compared to some alternative materials, its long-term advantages can lead to significant cost savings. The durability and mechanical strength of this material result in fewer repairs and replacements, lowering maintenance expenses over time. Furthermore, by improving energy efficiency in devices, manufacturers may also see a reduction in operational costs, making it a cost-effective choice in the long run.

Q3: In what electronic devices is zirconium silicate commonly used?

This versatile material is employed in a variety of electronic applications. Primarily, it is found in semiconductors as a dielectric material, crucial for miniaturizing components without sacrificing performance. It also plays a vital role in capacitors, enhancing energy storage capabilities, and in resistors, where it provides stability during temperature fluctuations. Additionally, many modern display technologies, such as LCDs and LEDs, benefit from its insulating properties, allowing for improved brightness and reliability.

Q4: Are there safety concerns associated with zirconium silicate?

Safety is a critical consideration in electronics manufacturing, and zirconium silicate is generally regarded as a safe choice. Its high thermal stability helps mitigate risks associated with overheating, which can lead to device failures or even hazards like fires. Moreover, this compound is non-toxic, making it a safer alternative to certain synthetic materials that may release harmful substances. Its compliance with safety regulations further enhances its appeal for manufacturers focused on creating reliable and safe electronic products.

Q5: What are the environmental impacts of zirconium silicate?

Zirconium silicate typically has a lower environmental impact compared to many synthetic materials used in electronics. Its production processes are generally less harmful, and the material itself is chemically inert, posing minimal risks to health and the environment. As sustainability becomes more critical in manufacturing, using this material can align with ecological goals, as it contributes to energy-efficient designs and has a longer lifespan, ultimately reducing waste and the carbon footprint associated with electronic devices.