When it comes to zirconium silicate processing, companies face the ongoing challenge of improving efficiency while keeping costs manageable. In an industry where precision and quality are paramount, recognizing the innovations that drive processing efficiency can significantly enhance production outcomes. This article provides solutions and insights that help address common concerns, focusing on the latest advancements in technology and their practical implications. With expert knowledge in the field, we aim to equip decision-makers with the information they need to boost their production capabilities effectively.

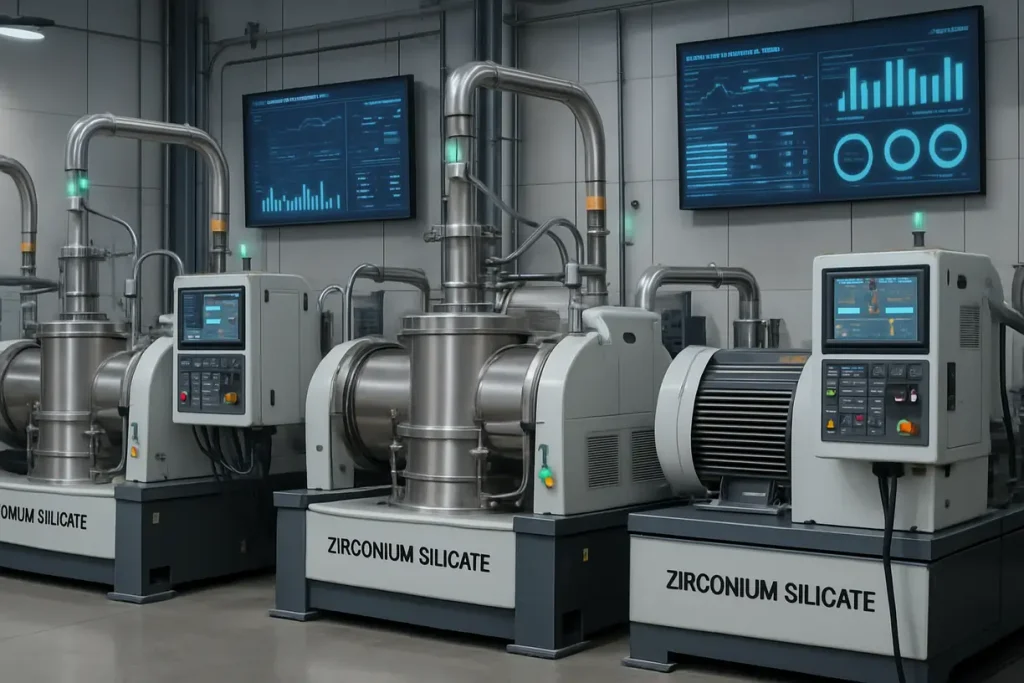

This image illustrates a modern zirconium silicate processing machine in operation.

What Are the Key Innovations in Zirconium Silicate Processing?

Recent years have seen several key innovations that have transformed zirconium silicate processing. These advancements include improved processing techniques, enhanced machinery, and innovative software solutions. Each of these elements plays a crucial role in streamlining operations and increasing output.

For example, the integration of automation and robotics has brought a significant shift in how companies manage their processing lines. Automated systems can handle repetitive tasks with greater precision and speed than manual labor, leading to higher overall efficiency. Alongside this, the introduction of advanced data analytics allows companies to gather insights into their operations, leading to smarter decision-making.

Furthermore, many businesses are adopting state-of-the-art technologies such as machine learning. By applying machine learning algorithms, companies can optimize their processing methods over time, automatically adjusting parameters to ensure maximum efficiency and minimum waste.

It’s also worth noting the development of environmentally friendly techniques. These innovations not only promote sustainability but can also reduce operational costs. Technologies that minimize energy consumption or use sustainable materials are becoming increasingly popular among businesses striving for greener production methods.

Key Innovations:

- Automation of processing lines

- Advanced data analytics tools

- Machine learning for method optimization

- Environmentally friendly processing techniques

- Sustainable material usage

How Do These Innovations Enhance Production Efficiency?

The enhancements from these innovations lead to significant gains in production efficiency. One major benefit is the time saved during the processing stages. Automated machines can operate continuously, reducing downtime and allowing companies to meet higher demand levels more easily.

Additionally, innovations in processing techniques help reduce waste and rework. For instance, by improving the precision of processing methods, companies can decrease the amount of raw material wasted. This not only lowers costs but also contributes to a more sustainable production approach.

Cost-effectiveness is another critical factor. Automating processes reduces the need for a large manual workforce, leading to lower labor costs. Moreover, enhanced processing methods often require less energy and resources, contributing to overall savings.

There is also a qualitative improvement in the products produced. Advances in technology often lead to higher-quality zirconium silicate, enabling businesses to offer products that meet stricter quality standards. This, in turn, can enhance customer satisfaction and strengthen brand reputation.

To summarize, the innovations driving efficiency in zirconium silicate processing provide a holistic approach to improving operations—helping companies save time, reduce waste, and lower costs while enhancing product quality.

| Innovation | Impact on Efficiency | Cost Benefit |

|---|---|---|

| Automation | Reduces downtime and speeds up processes | Lowers labor costs |

| Advanced Analytics | Smarter decision-making | Improves resource usage |

| Sustainable Practices | Minimizes waste and energy consumption | Reduces operational expenses |

What Role Does Research and Development Play?

Research and Development (R&D) are vital to the ongoing advancement of zirconium silicate processing technologies. Investing in R&D not only opens doors to innovative solutions but also allows companies to stay competitive in a rapidly evolving market.

One of the primary roles of R&D is to identify new materials and process improvements. Companies that invest in this area can uncover novel methodologies that enhance efficiency and product quality. Collaborating with academic institutions can lead to groundbreaking research, providing insights that businesses might not achieve independently. These partnerships often result in significant advancements that benefit the entire industry.

Common Areas of Focus in R&D:

- Development of new processing materials

- Improvement of existing techniques

- Environmental impact studies

- Collaboration with research institutes

- Testing and validation of new processes

Case studies exemplify the power of R&D. For instance, a notable manufacturer partnered with a university to explore new processing techniques, which resulted in a new material formulation that increased efficiency by 30%. Such collaborations highlight the tangible benefits that arise from focused research efforts.

Furthermore, ongoing R&D ensures that companies remain compliant with ever-changing regulations related to environmental impact and product safety. This proactive approach not only mitigates risks but also positions companies as leaders in adopting sustainable practices.

In conclusion, the role of R&D in zirconium silicate processing is critical. It not only introduces innovations that improve efficiency but also strengthens partnerships that lead to industry-wide benefits.

Which Equipment and Tools Are Essential for These Innovations?

To capitalize on innovations in zirconium silicate processing, businesses must invest in the right equipment and tools. This involves upgrading or acquiring machinery that supports advanced processing techniques.

Modern machinery designed for zirconium processing can significantly enhance productivity. Features such as automated controls, smart sensors, and real-time data analytics capabilities allow for greater precision in production. For example, high-capacity mills equipped with intelligent monitoring systems can optimize grinding processes, thereby reducing product losses.

In addition, software solutions are crucial. Tools that facilitate resource management, workflow automation, and quality control are now standard in successful operations. Such software helps track performance metrics, enabling businesses to make informed adjustments quickly.

Some key equipment to consider includes:

- High-capacity milling machines

- Automated sorting systems

- Real-time monitoring software

- Quality control tools

- Predictive maintenance technology

Maintenance tools are equally important. Regular maintenance ensures that machines operate at optimal levels, minimizing downtime and preventing costly repairs. Companies should invest in diagnostic tools that provide insights into machinery performance and alert staff to potential issues before they escalate.

To illustrate, a leading zirconium producer recently integrated advanced predictive maintenance technology into its operations. This innovation improved uptime by 25%, demonstrating how investing in the right tools can lead to tangible benefits.

In summary, equipping a facility with modern machinery, effective software solutions, and robust maintenance tools is essential for fully leveraging innovations in zirconium silicate processing.

| Equipment/Tool | Purpose | Benefit |

|---|---|---|

| High-capacity mills | Enhance grinding efficiency | Reduces product loss |

| Workflow automation tools | Streamline production processes | Saves time and labor |

| Diagnostic maintenance tools | Identify machinery issues early | Minimizes downtime |

This image shows advanced processing equipment used in zirconium silicate production.

How Are Environmental Considerations Impacting Innovations?

Environmental considerations are increasingly shaping the innovations within zirconium silicate processing. The industry faces rising pressure to adopt sustainable practices, spurred by regulatory requirements and consumer demand for eco-friendly products.

Technologies aimed at reducing energy consumption are at the forefront of industry innovations. For example, improved furnaces designed to optimize combustion efficiency can substantially cut energy usage during zirconium processing. This not only helps companies lower their operational costs but also lessens their environmental footprint.

Examples of Sustainable Innovations:

- Energy-efficient furnace designs

- Water recycling systems

- Waste reduction technologies

- Use of renewable energy sources

- Sustainable raw material sourcing

Additionally, advancements in waste management technology are becoming crucial. New systems are being developed to recycle by-products generated during processing. This not only helps reduce landfill waste but also allows companies to reclaim valuable resources, translating into substantial cost savings.

Regulatory influences also drive innovation. Governments are increasingly imposing stricter environmental regulations, compelling businesses to rethink their processing methods. Companies that proactively work towards compliance can avoid penalties and position themselves positively in the eyes of consumers.

Overall, the push for sustainability is driving meaningful innovation in zirconium silicate processing. Companies that embrace these changes are not only helping to protect the environment but also reaping financial and reputational benefits.

What Challenges Do Companies Face in Implementing Innovations?

Despite the clear advantages of adopting innovations in zirconium silicate processing, companies often encounter significant challenges. Understanding these hurdles is vital for successful implementation.

One common challenge is resistance to change among employees. Staff may be hesitant to adopt new technologies, especially if they are accustomed to traditional methods. To overcome this resistance, organizations must prioritize change management strategies. This includes providing thorough training and clear communication about the benefits of new processes.

Strategies to Overcome Challenges:

- Continuous training programs for employees

- Clear communication of change benefits

- Involvement of staff in the innovation process

- Financial assessment and planning for technology upgrades

- Setting realistic timelines for implementation

Another obstacle is the high initial investment costs associated with upgrading equipment and training staff. Although innovations can lead to long-term savings, the upfront costs can deter companies from making necessary changes. It may be beneficial to evaluate financing options or phased implementations that ease the financial burden.

Skill gaps within the workforce can also present challenges. As technologies evolve, it’s essential that employees possess the required skills to operate new equipment and methodologies. Implementing training programs specifically tailored to these needs is crucial for success.

Ultimately, being proactive about addressing these challenges can smooth the transition to more efficient and innovative processes. This approach can significantly enhance the chance of long-term success in zirconium silicate processing.

| Challenge | Description | Suggested Solution |

|---|---|---|

| Resistance to Change | Employees may hesitate to adopt new technologies | Provide thorough training |

| High Initial Costs | Upgrading can be expensive | Evaluate financing options |

| Skill Gaps | Employees may lack necessary skills | Implement targeted training |

How Can Companies Successfully Integrate New Technologies?

Integrating new technologies into zirconium silicate processing requires careful planning and execution. Companies can adopt specific strategies to ensure a smooth transition.

First, it is crucial to outline a step-by-step integration strategy. This plan should detail each phase of integration, from initial assessments of existing processes to testing new systems. Clear timelines and milestones will help keep the integration on track.

Second, change management is essential. Companies should provide comprehensive training to familiarize employees with new technologies. Open communication about the benefits and goals of the changes will encourage staff buy-in, fostering a culture of innovation.

Third, regular evaluations of the integration process should be conducted to identify areas for improvement. Feedback from employees who interact with the new systems regularly can provide invaluable insights into their effectiveness.

Effective Integration Steps:

- Assess current systems and processes

- Set clear goals for technology integration

- Train employees early to gain buy-in

- Monitor progress regularly and adjust plans as needed

- Celebrate successes to maintain morale

By approaching integration methodically, businesses can minimize disruptions and maximize the benefits of new technologies.

| Integration Strategy | Description | Timeline |

|---|---|---|

| Step-by-Step Plan | Outline each phase of integration | Define clear timelines |

| Change Management | Ensure employees understand and accept changes | Provide ongoing support |

| Regular Evaluations | Assess integration effectiveness | Schedule periodic reviews |

What Future Trends Could Transform Zirconium Processing?

Looking ahead, several trends are likely to impact zirconium silicate processing in significant ways. Staying informed about these developments can help companies plan strategically for the future.

One such trend is the increased reliance on AI and automation. As artificial intelligence technologies advance, businesses can expect more sophisticated automation tools. These innovations will allow for even more efficient operations and improved decision-making based on real-time data analysis.

Another trend is the growing emphasis on sustainability. As environmental concerns become more pronounced, companies will need to prioritize eco-friendly practices. Innovations focused on reducing waste and energy consumption will be critical in meeting both regulatory standards and consumer expectations.

Future Trends to Watch:

- More advanced AI tools for data-driven decision-making

- Greater use of automation and robotics in processing

- Increased emphasis on recycling and resource recovery

- New regulatory requirements promoting sustainability

- Development of alternative raw materials

Moreover, the adoption of advanced materials will likely gain momentum. Research into alternative materials and processing methods could result in new, more efficient ways to produce zirconium silicate.

These trends suggest a future where the zirconium processing industry becomes more efficient, sustainable, and technologically advanced. Staying ahead of these changes will be essential for companies aiming to maintain competitive advantages.

How Do These Innovations Affect the End Products?

The innovations in zirconium silicate processing have a direct impact on the end products produced. As companies adopt advanced technologies, the quality and performance of these products often improve.

One notable benefit is the greater consistency in product quality. Enhanced processing techniques reduce variability, resulting in zirconium silicate that meets higher standards. This consistency can lead to improved customer satisfaction, fostering strong relationships with clients.

Moreover, innovations often enable the development of specialized products. With more precise processing methods, companies can create zirconium silicate tailored to specific applications, meeting diverse customer needs effectively.

Customer Benefits of Innovations:

- Higher quality and durability of final products

- Customization options for specific applications

- Increased reliability in product performance

- Reduced lead time for orders

Feedback from customers frequently highlights these improvements. Product quality, durability, and performance often rank high on customer priority lists, and advancements in processing can directly address these areas.

Ultimately, the innovations affecting zirconium silicate processing lead to higher-quality end products, demonstrating that investing in technology pays off not just for manufacturers but for their clients as well.

| Impact on Products | Description | Customer Benefit |

|---|---|---|

| Increased Consistency | Reduces variability in quality | Higher customer satisfaction |

| Specialized Products | Tailored solutions for specific applications | Meets diverse customer needs |

What Are Best Practices for Keeping Up with Industry Innovations?

In an evolving field like zirconium silicate processing, keeping up with industry innovations is vital. Companies can adopt several best practices to stay informed and adaptable.

First, continuous monitoring of industry trends is essential. This can involve subscribing to industry newsletters, attending conferences, and engaging in professional networks. Staying informed helps businesses identify emerging technologies and trends early.

Second, participation in trade shows offers opportunities to see new products and technologies firsthand. Networking at these events can lead to valuable connections and insights that drive innovation within an organization.

Effective Practices to Stay Updated:

- Attend workshops and training sessions

- Join industry associations and groups

- Follow influential figures on social media

- Regularly review publications and research papers

- Conduct surveys to gauge market needs

Finally, companies should engage with thought leaders in the industry. This could involve following experts on social media, participating in webinars, or attending panel discussions. These interactions provide insights that can guide strategic planning and decision-making.

By proactively pursuing these best practices, businesses in the zirconium silicate sector will be better positioned to adapt to changes and seize new opportunities.

| Best Practice | Description | Expected Outcome |

|---|---|---|

| Continuous Monitoring | Stay updated on industry trends | Early identification of innovations |

| Trade Show Participation | See new technologies and network with peers | Valuable industry insights |

| Engagement with Thought Leaders | Gain insights from experts | Informed strategic planning |

This image captures an industry event showcasing innovations in zirconium silicate processing.

Conclusion

In summary, innovations in zirconium silicate processing hold the potential to radically transform efficiency and product quality. From automation and advanced analytics to sustainability practices, these advancements offer substantial benefits for businesses. By embracing new technologies, companies can enhance productivity and ultimately improve customer satisfaction. For further assistance in navigating these advancements, contact Global Industry today. Let us help you stay ahead in zirconium silicate processing and foster long-term success for your organization.

FAQ Section

Q1: What are the primary benefits of innovative zirconium processing techniques?

Innovative zirconium processing techniques offer numerous benefits, including increased operational efficiency, significant reductions in material waste, and cost savings in production processes. These advancements often lead to higher quality end products, which can help companies meet or exceed industry standards, thus enhancing customer satisfaction and potentially increasing market share.

Q2: How can companies evaluate the effectiveness of new technologies?

Companies can evaluate the effectiveness of new technologies by measuring key performance indicators (KPIs) such as production output, operational costs, and turnaround times. Other metrics could include the reduction in waste generated, improvements in product quality, and overall labor efficiency. Regular performance reviews and comparative analysis before and after technology implementation can provide clear insights into effectiveness.

Q3: What training is required for implementing new zirconium technologies?

Implementing new zirconium technologies typically requires comprehensive training programs that address various aspects, including equipment operation, software utilization, and process management. Training should also focus on safety protocols and troubleshooting methods to empower employees to handle new systems independently and effectively. Ongoing training sessions can ensure that staff are updated on the latest advancements.

Q4: Are there environmental regulations affecting zirconium processing innovations?

Yes, environmental regulations significantly influence zirconium processing innovations. Many regions enforce strict guidelines on emissions, waste disposal, and resource usage, compelling companies to adopt greener technologies and practices. Staying informed about regulatory changes helps manufacturers not only comply with these laws but also enhances their reputation as environmentally responsible businesses, which can attract eco-conscious consumers.

Q5: How can firms remain competitive in the face of rapid technological change?

To remain competitive amidst rapid technological changes, firms should adopt a proactive approach by continually monitoring industry trends and investing in research and development. This includes fostering a culture of innovation that encourages employees to become adaptive and open to change. Additionally, forming strategic partnerships with technology providers and participating in industry coalitions can provide valuable insights and resources for companies to stay ahead in the market.