In the production of zirconium silicate, ensuring quality control is critical for manufacturers. Many companies face challenges in maintaining consistency and meeting standards, leading to concerns about product reliability and customer satisfaction. This article examines essential quality control measures specifically for zirconium silicate production, addressing common pain points and providing actionable solutions. With a focus on practical strategies and industry best practices, this guide equips purchasing managers and decision-makers with the knowledge needed to enhance quality and boost confidence in their products.

What Are the Basics of Zirconium Silicate Production?

Zirconium silicate is a mineral primarily used in various industries, including ceramics, refractories, and coatings, due to its unique properties such as high thermal stability, chemical resistance, and low thermal expansion. Understanding the fundamentals of its production is vital for manufacturers who aim to deliver high-quality products.

The production process generally involves several stages, including:

- Mining: The extraction of raw zircon from the earth, sourced from mineral sands.

- Refining: The initial steps to remove impurities and concentrate the material.

- Processing: Converting the refined material into a fine powder suitable for various applications.

During these stages, consistency in particle size and the purity of materials are paramount. Even a small amount of impurities can significantly impact the final product’s properties, which is why immediate quality oversight is crucial.

To ensure optimal results, manufacturers should consider the following factors that affect quality:

- Particle size distribution: Ensuring uniformity in size helps in the performance of zirconium silicate in various applications.

- Impurity levels: Minimizing impurities enhances the overall quality and effectiveness of the end product.

- Uniformity in texture: Consistent texture contributes to reliable processing in ceramic and refractory applications.

- Chemical composition: Accurate formulations ensure that zirconium silicate meets specific industry requirements.

Given these considerations, producers need to adopt a proactive approach to quality control throughout the production process. One way to do this is by implementing a robust quality assurance framework that includes ongoing training and adherence to best practices.

Factors Affecting Zirconium Silicate Quality: A Quick Summary

| Factor | Influence on Quality |

|---|---|

| Raw Material Quality | Directly affects final product properties |

| Production Techniques | Variations can lead to inconsistent results |

| Environmental Conditions | Temperature and humidity can alter material integrity |

Take this into account: investing in high-quality materials and processes pays off by yielding superior end products and fostering customer trust. By understanding and addressing these fundamental aspects, manufacturers can significantly improve their production outcomes and maintain a competitive edge in the market.perior end products and fostering customer trust.

What Quality Control Measures Are Commonly Used?

Quality control in zirconium silicate production comprises a range of industry-standard practices aimed at ensuring products conform to specific specifications and customer expectations. These measures are vital for maintaining high standards and consistent output.

The first step typically involves regular inspections throughout the production process. Inspections may include visual assessments, tactile evaluations, or advanced technology applications to identify any issues early on. In addition, product samples are frequently subjected to rigorous testing to verify that they meet established benchmarks. By inspecting at every stage, manufacturers are better equipped to catch and address inconsistencies proactively.

Certifications also play a crucial role in solidifying overall quality. Many companies pursue ISO certifications to demonstrate their commitment to quality management systems, which enhances customer confidence. Achieving such certifications not only adds prestige to a brand but also positions the company more favorably in competitive bidding processes.

Other common quality control measures encompass the following:

- Setting clear and achievable specifications for raw materials to ensure reliability from the start.

- Conducting routine audits of production processes to verify adherence to quality standards and identify areas for improvement.

- Implementing software systems that track quality metrics over time, allowing manufacturers to identify trends and address problems promptly.

In essence, these measures form a comprehensive framework that underscores the importance of quality throughout the production lifecycle. Emphasizing a proactive and systematic approach to quality control is necessary for long-term success. Thus, having a robust framework for quality control is not just beneficial but essential for maintaining a competitive edge.

How Does Material Sourcing Affect Quality?

Material sourcing plays a crucial role in determining the overall quality of zirconium silicate. High-quality raw materials not only influence production efficacy but also directly impact the properties and performance characteristics of the final product. A thorough understanding of sourcing practices is essential for manufacturers aiming for excellence.

Selecting the right suppliers is foundational to achieving consistent quality. Companies should evaluate potential suppliers based not only on their ability to deliver high-quality materials but also on their reliability and adherence to ethical practices. This includes assessing their transportation logistics and storage capabilities, which can further impact material integrity.

Moreover, the presence of impurities can significantly detract from product performance. Companies should conduct extensive testing of all incoming materials prior to their use in production. This preemptive quality control measure is vital to ensure that only the best materials enter the manufacturing process, thereby maintaining consistency and reliability in the final product.

Open lines of communication with suppliers are equally important for preserving quality. Regular dialogue enables manufacturers to address any material concerns promptly, allowing for timely solutions that mitigate risks.

To further illustrate the importance of sourcing, here is a concise table summarizing key factors affecting material sourcing:

| Aspect | Effect on Quality |

|---|---|

| Supplier certifications | Ensures consistent quality |

| Testing for impurities | Eliminates defects |

| Communication with suppliers | Solves issues proactively |

In addition to the factors mentioned in the table, manufacturers may also consider the following strategies to enhance their sourcing process:

- Long-term partnerships: Building lasting relationships with suppliers can promote trust and transparency.

- Diversified sourcing: Engaging multiple suppliers can reduce risks associated with material shortages or quality inconsistencies.

- Sustainability practices: Considering suppliers who prioritize eco-friendly sourcing can improve brand reputation and product appeal.

In essence, smart sourcing not only leads to better product quality but also strengthens the entire production process, laying a solid foundation for future growth and success. By focusing on these key elements, companies can significantly improve their quality control outcomes and drive customer satisfaction.lity products.

What Production Techniques Impact Quality Assurance?

Different production techniques have varying implications for the quality of zirconium silicate. Understanding these techniques can guide companies toward adopting the best practices for their operations.

Techniques such as milling, blending, and calcination are integral to creating high-quality zirconium silicate. Each step requires strict adherence to procedures to maintain product standards.

For instance, milling achieves the desired particle size, while blending ensures that ingredients are evenly distributed. Both elements are crucial in preventing inconsistency that can lead to quality issues.

It’s also worthwhile to explore how technology influences these production techniques. Automation is becoming increasingly prevalent in manufacturing, which aids in achieving precision and consistency. Automated systems can monitor various parameters in real-time, making adjustments to maintain quality as needed.

Here’s a table summarizing key production techniques and their impacts:

| Production Technique | Impact on Quality |

|---|---|

| Milling | Achieves precise particle size |

| Blending | Ensures uniformity of ingredients |

| Calcination | Enhances product stability |

When employed correctly, these techniques can elevate the quality of production. Companies that invest in advanced production methods often find that the quality of their zirconium silicate improves significantly.

What Testing Methods Validate Zirconium Silicate Quality?

Reliable testing methods are crucial in validating the quality of zirconium silicate products. These tests help ensure that the materials meet the required specifications and performance standards.

Common laboratory tests are essential to this validation process. For instance, chemical analysis is carried out to verify the mineral composition. Additionally, testing for factors like particle size and moisture content is equally vital.

Another pivotal element of validation is third-party testing. Engaging an independent laboratory for testing can provide an unbiased perspective. This reinforces credibility by demonstrating that the evaluation was not influenced by internal practices.

Here’s a quick summary of frequently used testing methods:

| Testing Method | Purpose |

|---|---|

| Chemical analysis | Verifies mineral composition |

| Particle size analysis | Ensures uniformity and quality |

| Third-party testing | Provides unbiased evaluation |

Implementing robust testing methods not only guarantees product quality but also strengthens customer trust.

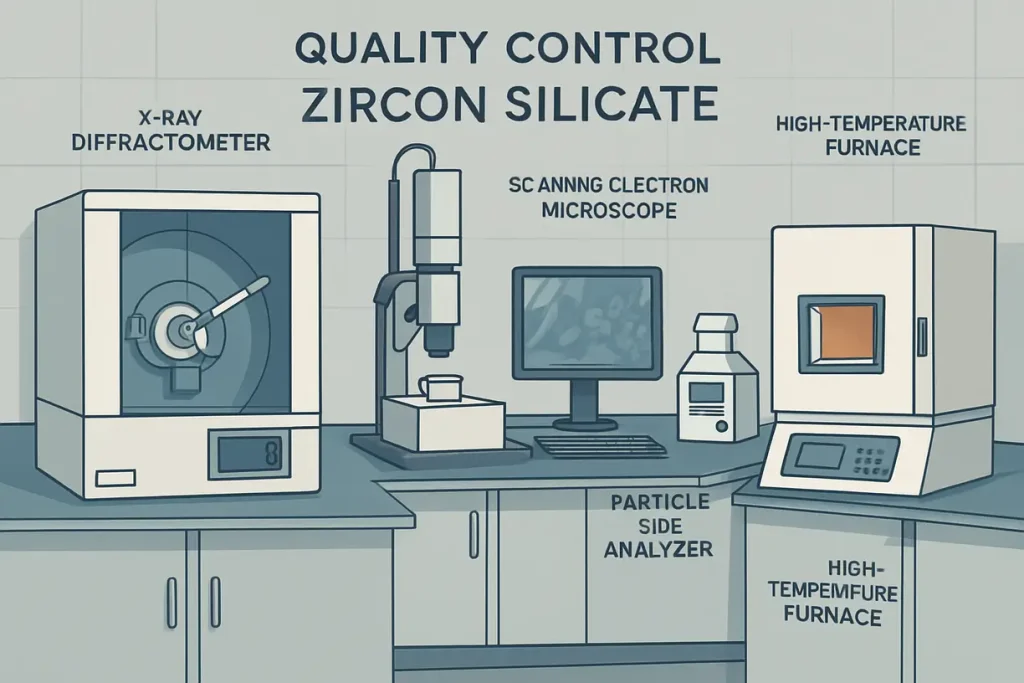

This image shows laboratory testing equipment used to analyze zirconium silicate quality, emphasizing the importance of rigorous testing.

How Do Environmental Factors Influence Quality Control?

Environmental factors play a significant role in the quality control of zirconium silicate production. Factors like temperature and humidity can drastically influence the material properties.

For instance, high humidity can lead to powder clumping, making it difficult to achieve the desired particle size and consistency. Therefore, it’s vital to implement strict monitoring systems to keep conditions stable.

Companies can benefit from installing climate control systems in warehouses and production areas. These systems help to maintain optimal conditions, ensuring that materials remain dry and consistent during processing.

Meanwhile, developing contingency protocols is equally as important. These protocols become essential whenever unexpected environmental changes pose a risk to product quality.

To summarize, here is a table illustrating how environmental factors affect quality:

| Environmental Factor | Impact on Quality |

|---|---|

| Temperature | Affects moisture content |

| Humidity | Influences material handling |

| Contingency protocols | Mitigates risks in unexpected changes |

Recognizing and managing these factors can lead to significant improvements in quality control.

What Role Does Employee Training Play in Quality Control?

Employee training is a critical aspect of quality control in zirconium silicate production. Well-trained staff help ensure that processes are followed accurately and consistently, ultimately impacting product quality.

Training programs should focus on various aspects of production, including equipment operation, quality standards, and safety procedures. Regular workshops and training sessions keep employees informed about the latest industry standards and practices.

Moreover, fostering a culture of quality enhances accountability among workers. When employees understand the importance of their roles, they are more likely to perform their tasks with diligence.

To highlight the importance of training, consider the following benefits:

| Benefit | Description |

|---|---|

| Improved accuracy | Ensures fewer mistakes during production |

| Enhanced safety | Reduces accidents and improves morale |

| Increased accountability | Motivates employees to uphold standards |

Ultimately, investing in employee training leads to enhanced product quality and overall operational success.

How Can Technology Improve Quality Control Measures?

Emerging technologies are significantly reshaping quality control measures in zirconium silicate production. Adopting innovative solutions can enhance accuracy and efficiency.

Quality management systems, for instance, provide real-time data monitoring. These systems analyze production metrics to ensure processes remain stable and meet quality standards. Automated systems can alert teams to deviations, allowing for quick corrective actions.

Furthermore, advancements in data analytics enable businesses to identify trends and predict potential quality issues. This proactive approach helps mitigate risks before they escalate into larger problems.

Here’s a brief overview of technological advancements:

| Technology | Benefits |

|---|---|

| Quality management systems | Real-time monitoring and alerts |

| Data analytics | Predictive insights for quality issues |

| Automation | Precision and consistency in production |

By leveraging technology effectively, companies can achieve remarkable advancements in quality control.

What Are the Challenges in Maintaining Quality Control?

Even with robust quality control practices, manufacturers face several challenges. Identifying and addressing these challenges is essential for consistent quality in zirconium silicate production.

One common issue is variations in raw materials. Even small changes can lead to significant differences in product quality. To combat this, manufacturers should implement rigorous supplier evaluation processes.

Another challenge is staying compliant with industry regulations. Regulations may change, requiring manufacturers to adapt their quality control measures accordingly.

Handling customer complaints and returns can also pose issues. Effective communication and swift action can turn negative experiences into opportunities for improvement.

Here’s a summary of the key challenges faced:

| Challenge | Solution |

|---|---|

| Variations in raw materials | Rigorous supplier evaluations |

| Compliance with regulations | Regular updates and training sessions |

| Customer complaints | Effective communication strategies |

Identifying and overcoming these challenges leads to improved quality control and customer satisfaction.

What Future Trends Affect Zirconium Silicate Quality Control?

Looking to the future, several trends are likely to influence quality control in zirconium silicate production. Keeping an eye on these trends will prepare manufacturers for upcoming changes.

Sustainability is emerging as a focal point in many industries, including zirconium silicate. Companies must adapt their processes to minimize environmental impact while maintaining quality.

Another trend is the integration of artificial intelligence in quality control. AI systems can analyze vast amounts of data, providing quick insights that help improve product quality.

Adapting to these trends will not only enhance product quality but also position companies favorably against competitors.

Here’s a brief overview of trends:

| Trend | Implication |

|---|---|

| Sustainability | Necessitates greener practices |

| Artificial intelligence | Facilitates data-driven decisions |

| Industry 4.0 | Drives automation and efficiency |

Embracing these future developments will lead to better quality control measures and competitiveness.

This image illustrates the packaging of zirconium silicate, showcasing quality branding and quality assurance measures.

Conclusion

In summary, this comprehensive guide has outlined the key quality control measures essential for zirconium silicate production. By focusing on these practices, manufacturers can ensure product consistency and excellence while effectively addressing potential challenges. The quantifiable benefit is clear: companies that implement these measures can significantly enhance their market position and elevate customer satisfaction.

Additionally, a commitment to quality control not only fosters brand loyalty but also opens doors to new business opportunities in an increasingly competitive landscape. To take your quality control efforts to the next level, consider partnering with Global Industry for expert insights. Explore our resources today to begin making impactful changes that drive your business forward. Together, we can work towards achieving excellence in every aspect of zirconium silicate production.

FAQ Section

Q1: What is zirconium silicate used for?

Zirconium silicate is primarily used in ceramics, especially for tiles and sanitary ware. Due to its high thermal stability and low expansion, it is also utilized in the production of refractories, coatings, additives, and as a pigment in various applications, including paints and plastics. Its unique properties make it valuable in industries requiring durable and resistant materials.

Q2: How can I ensure the quality of zirconium silicate?

Ensuring the quality of zirconium silicate involves implementing a series of robust quality control measures. This includes conducting regular inspections throughout the production process, performing laboratory tests to monitor the presence of impurities, and verifying the consistency of particle size distribution. Engaging reputable suppliers and obtaining certifications further strengthens the quality assurance process.

Q3: What are the common tests for verifying zirconium silicate quality?

Common tests for verifying the quality of zirconium silicate include chemical analysis to assess mineral composition, particle size analysis to ensure uniformity, and moisture content testing to prevent clumping. Additional tests might involve checking for impurities and performing quality audits to maintain strict adherence to standards.

Q4: Why is supplier evaluation crucial for quality control?

Supplier evaluation is crucial because the quality of the raw materials significantly impacts the final product’s performance. By assessing suppliers based on their quality, reliability, and certification status, companies can minimize the risk of inconsistencies and defects. Regular evaluations facilitate strong partnerships and ensure that only high-quality materials are used in production.

Q5: How often should quality control measures be reviewed?

Quality control measures should be reviewed regularly, ideally at least annually, or whenever there are changes in production processes, suppliers, or market demands. Ongoing assessment ensures that measures remain effective in addressing potential issues, adapting to new regulations, and incorporating advancements in technology to enhance quality.