In today’s landscape of advanced materials, stabilized zirconia powder stands out for its unique properties and vast applications. However, industries rely on ongoing research to further enhance its performance. Many companies face complex challenges when selecting materials that can withstand demanding environments. This article addresses these concerns by discussing the latest research advancements that significantly improve the properties of stabilized zirconia powder. These developments can lead to better material performance and efficiency in various industrial applications. Trust in our analysis, as we explore the significant improvements that come from recent research.

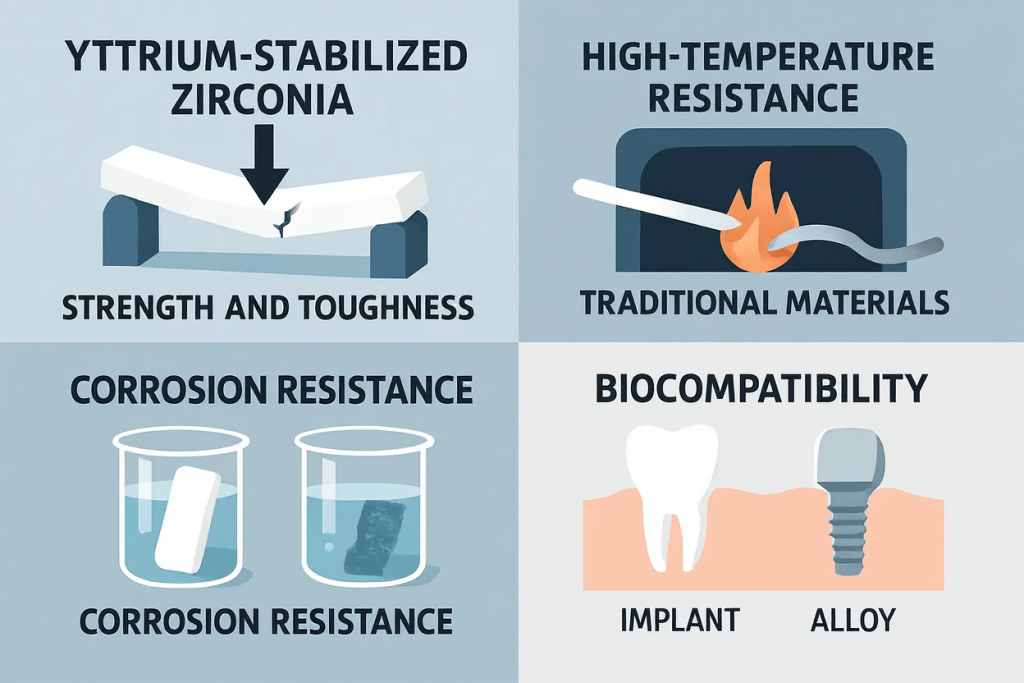

This image represents stabilized zirconia powder used in various industrial applications for its superior properties.

How Have Research Advances Improved Stabilized Zirconia Powder Properties?

The core of stabilized zirconia powder lies in its exceptional characteristics, such as high strength and thermal stability. Researchers have made various advancements that help enhance these features. These improvements stem from introducing new processing techniques and innovative additives.

One of the most noteworthy advancements relates to synthesis methods. Traditional methods often limited the material’s potential. New techniques, such as sol-gel processing and microwave-assisted synthesis, have shown promising results. These approaches allow control over particle size and distribution, leading to improved mechanical and thermal properties. By precisely adjusting these parameters, researchers can produce zirconia with superior toughness and durability.

Another significant area of research focuses on the use of dopants and additives. Materials like yttria and ceria are commonly used to stabilize the zirconia phase. However, researchers continuously explore new alternatives that can further optimize these properties. By experimenting with different combinations of dopants, they can enhance the ion conductivity and lower the operating temperatures for applications such as solid oxide fuel cells (SOFCs). This continual effort is essential for industries reliant on zirconia, such as ceramics, electronics, and biotechnology.

Furthermore, advancements in characterization techniques allow for a more profound understanding of how these modifications affect the material’s performance. This leads to targeted innovations that maximize the benefits of stabilized zirconia in real-world applications.

Key Points:

- Advancements in synthesis methods boost performance.

- Innovative dopants lead to enhanced properties.

- Research continually seeks optimizations for various applications.

Here is a summary of how different synthesis methods have evolved and their impact on properties.

| Synthesis Method | Key Features | Impact on Properties |

|---|---|---|

| Traditional Methods | Limited control over particle size | Inconsistent material characteristics |

| Sol-Gel Processing | Fine control of composition and size | Enhanced mechanical strength |

| Microwave-Assisted Synthesis | Rapid processing with uniform particles | Improved thermal stability |

| Hydrothermal Synthesis | High pressure and temperature processing | Superior structural integrity |

What Are the Key Properties of Stabilized Zirconia Powder?

Stabilized zirconia powder possesses several key properties that make it invaluable across various industries. Understanding these properties helps organizations choose the right materials for their applications.

First, the mechanical strength of stabilized zirconia is extraordinary. It maintains integrity under extreme stress, making it suitable for high-load applications. Additionally, its toughness prevents crack propagation, extending the product’s lifespan.

Next, the thermal properties are notable. Stabilized zirconia demonstrates excellent thermal insulation, which is critical in applications exposed to varying temperatures. Its resistance to thermal shock is also essential in processes where rapid temperature changes occur.

Chemically, stabilized zirconia showcases impressive resistance to corrosion and wear. This is vital in environments where materials may face aggressive chemicals or abrasive surfaces. The combination of these properties ensures that stabilized zirconia remains a top choice for industries like aerospace, automotive, and medical devices.

To summarize:

- Mechanical strength offers durability.

- Thermal insulation provides protection under extreme conditions.

- Chemical resistance ensures longevity in harsh environments.

Here’s a comparative view of key properties.

| Property | Stabilized Zirconia | Traditional Materials |

|---|---|---|

| Mechanical Strength | Very high | Moderate |

| Thermal Insulation | Excellent | Poor to moderate |

| Corrosion Resistance | Superior | Varies |

| Wear Resistance | Exceptional | Generally low |

This image illustrates the key properties of stabilized zirconia compared to traditional materials.

Which Research Advances Have Influenced Stability?

Recent research has driven significant advancements in the stability of stabilized zirconia powder. Understanding these influences can guide organizations in maximizing the potential of their materials.

Synthesis methods have evolved significantly, leading to improved phase stability. Specifically, researchers are experimenting with various temperatures and pressures during processing to enhance stability, which improves the material’s resistive capacities.

Moreover, the role of additives cannot be overlooked. Recent studies have highlighted the effectiveness of using different combinations of dopants. By fine-tuning these additives, researchers have demonstrated how to maintain stability even under harsh operational conditions.

Furthermore, innovative surface modifications have gained attention. Techniques such as coating processes can enhance the resistance to environmental factors. These developments contribute to the longevity and reliability of zirconium-based materials tailored for specific applications.

In brief:

- Improved synthesis methods enhance phase stability.

- Fine-tuning additives leads to better performance.

- Surface modifications increase resistance to environmental effects.

Here’s a table summarizing recent research findings.

| Research Area | Recent Findings | Impact on Stability |

|---|---|---|

| Synthesis Techniques | Higher temperatures optimize stability | Improved resistive ability |

| Additive Combinations | New dopants enhance resilience | Longer material lifespan |

| Surface Modifications | Coating techniques resist environmental damage | Increased longevity |

How Do These Advances Impact Industrial Applications?

The implications of advancements in stabilized zirconia properties are vast, impacting many industrial sectors.

In manufacturing, companies leverage improved mechanical properties to produce more durable components. For instance, parts made from advanced stabilized zirconia can withstand higher stresses without failing, directly benefiting industries like automotive and aerospace. Enhanced toughness also allows for the creation of lighter yet stronger parts, improving fuel efficiency and overall performance in vehicles and aircraft.

In biomedical applications, the enhanced thermal and chemical properties make stabilized zirconia an ideal choice for implants and prosthetics. Its biocompatibility ensures minimal adverse reactions within the human body, making it a favorite in medical technology. This allows for the development of long-lasting dental crowns and hip implants that can withstand the dynamic conditions of the human body over time.

For the aerospace industry, the importance of resistance to extreme temperatures cannot be overstated. Advanced stabilized zirconia offers significant advantages in components exposed to high heat and mechanical wear, contributing to safer and more efficient flight technologies. The ability to perform reliably in jet engines and thermal barrier coatings ultimately leads to improved aircraft safety and longevity.

Additionally, the electronics industry benefits as stabilized zirconia powders are increasingly used in fuel cells and solid oxide fuel cell systems, boosting energy efficiency and reducing emissions.

Takeaway:

- Enhanced properties lead to stronger components in manufacturing.

- Improved performance boosts reliability in biomedicine.

- Resistance to heat aids aerospace innovation.

- Applications in electronics contribute to sustainable energy solutions.

Here’s a snapshot of the industrial applications.

| Industry | Application | Benefits |

|---|---|---|

| Manufacturing | Durability of components | Extended lifespan |

| Biomedical | Implants and prosthetics | High biocompatibility |

| Aerospace | Engine components | Improved heat resistance |

| Electronics | Fuel cells and energy systems | Enhanced energy efficiency |

What Are the Emerging Trends in Stabilized Zirconia Research?

Emerging trends in stabilized zirconia research are critical for industries seeking innovation. Keeping up with these trends can provide a competitive edge.

Nanotechnology, for instance, is increasingly being incorporated. Researchers are looking into nanoscale modifications, which can enhance the mechanical strength and thermal stability of stabilized zirconia even further. These advancements not only improve the material’s performance but could also lead to the development of new applications that were previously unattainable.

Another trend is focusing on eco-friendly approaches to material synthesis. Sustainability is becoming a priority in research agendas, prompting companies to investigate greener methods. These practices contribute to decreased environmental impact and often lead to cost savings in the production process. As regulations tighten and consumer preferences shift toward sustainable options, this trend in eco-friendly synthesis will likely gain momentum.

Moreover, interdisciplinary approaches are proving valuable. Engaging experts from different fields allows for holistic advancements that consider mechanical, chemical, and biological factors. For instance, collaborations between materials scientists and biologists are enhancing the biocompatibility of zirconia for use in medical applications, resulting in materials that are not only effective but also safe for human use.

Additionally, the integration of artificial intelligence (AI) and machine learning is revolutionizing how researchers approach material design and analysis. By leveraging AI, researchers can predict the performance of zirconia formulations, identify optimal processing conditions, and accelerate the discovery of new applications.

In summary:

- Nanotechnology offers potential for enhanced properties.

- Eco-friendly methods address sustainability concerns.

- Interdisciplinary research drives innovation across fields.

- AI integration improves research efficiency and accuracy.

Here’s a glimpse into future research directions.

| Future Direction | Description | Potential Impact |

|---|---|---|

| Biocompatibility | Development for medical use | Enhanced implant performance |

| Smart Materials | Integration of sensing capabilities | Real-time applications |

| 3D Printing | Innovative design capabilities | Customization of products |

How Can Businesses Leverage Enhanced Zirconia Properties?

For businesses looking to capitalize on enhanced zirconia properties, several strategies can be employed.

First, it is crucial to assess the specific applications of stabilized zirconia in current product offerings. Understanding which properties are most beneficial can guide material selection and product development. By aligning the unique characteristics of stabilized zirconia with specific industry needs, companies can create optimized solutions that improve performance.

Next, businesses should consider partnerships with research institutions. Collaborating with academic and industrial partners can lead to new insights and innovations. This can drive product enhancements and keep companies ahead of competitors. Such partnerships can also provide access to cutting-edge research, allowing businesses to adopt the latest techniques and findings more rapidly.

Additionally, implementing training for staff on new developments can improve operational efficiency. When teams are knowledgeable about the latest advancements, they can apply them effectively, leading to better products and processes. Regular workshops and knowledge-sharing sessions can help cultivate a culture of continuous learning.

Finally, investing in research and development (R&D) programs can significantly bolster a business’s capabilities. Allocating resources to explore new applications and innovative uses of stabilized zirconia can result in breakthrough products that set the company apart in the market.

In essence:

- Assessing applications helps guide material choice.

- Partnerships with research institutions foster innovation.

- Staff training ensures efficient implementation of new techniques.

- Investing in R&D can lead to breakthrough products.

Here’s a table of strategies and their potential benefits.

| Strategy | Description | Potential Benefit |

|---|---|---|

| Application Assessment | Evaluate current products | Informed material selection |

| Research Partnerships | Collaborate with institutions | Drive innovation |

| Staff Training | Educate teams on new materials | Increased efficiency |

| Investment in R&D | Allocate resources to explore new uses | Competitive advantage in market |

What Challenges Remain in Stabilized Zirconia Research?

Despite considerable advancements, several challenges persist in stabilized zirconia research.

One significant challenge is material degradation. Understanding how zirconia behaves under extreme conditions is essential for maximizing its lifespan. Continuous studies aim to uncover the mechanisms behind degradation in specific environments.

Regulatory compliance also poses difficulties. Industries must adhere to various regulations, which often change over time. Staying updated is crucial, as non-compliance can lead to costly consequences.

Finally, a shortage of skilled personnel in relevant fields can hamper research progress. Companies often struggle with finding experts familiar with the latest technologies and procedures necessary for advancement.

Key challenges include:

- Material degradation under extreme conditions.

- Keeping pace with regulatory changes.

- Finding skilled personnel for advanced research.

Here’s a summary of remaining challenges.

| Challenge | Description | Implication |

|---|---|---|

| Material Degradation | Understanding long-term effects | Affects product reliability |

| Regulatory Compliance | Adhering to changing regulations | Risk of financial penalties |

| Skilled Personnel Shortage | Lack of expertise in advanced technologies | Slows research progress |

How Can Companies Stay Informed on Research Advances?

To remain competitive, companies must stay informed about the latest research advancements in stabilized zirconia.

One effective strategy is to subscribe to industry journals and publications. Staying updated on recent studies and findings ensures organizations remain aware of shifts in technology and practices.

Attending industry conferences and workshops can also provide valuable insights. These events often feature expert speakers and discussions on the latest advancements, facilitating knowledge exchange.

Networking with research institutions can further enhance awareness. Collaborations and partnerships help companies tap into cutting-edge research and foster innovation within their operations.

To recap:

- Subscribing to journals ensures awareness of studies.

- Conferences foster knowledge exchange.

- Networking promotes collaboration and access to new research.

Here’s a concise table of strategies for staying informed.

| Strategy | Description | Benefit |

|---|---|---|

| Journal Subscriptions | Read industry-relevant publications | Timely updates on research |

| Conferences | Attend events and workshops | Networking opportunities |

| Research Collaboration | Engage with institutions | Access to cutting-edge advancements |

What Are the Future Directions of Stabilized Zirconia Powder Research?

Looking ahead, the future of stabilized zirconia research holds vast potential for continued advancements.

Researchers predict significant growth in the use of biocompatible zirconia in medical applications. The focus on developing materials that cause minimal reaction within the body is crucial for future implant designs.

Moreover, the integration of smart materials is set to gain momentum. Efforts are underway to explore how zirconia can incorporate sensing capabilities, allowing for real-time monitoring in various applications.

Finally, 3D printing technology presents exciting opportunities. The ability to create complex shapes and structures from stabilized zirconia will enable innovative designs that meet specific industry needs.

In summary:

- Biocompatibility will drive growth in medical applications.

- Smart materials may allow real-time monitoring.

- 3D printing opens new design possibilities.

Here’s a glimpse into future research directions.

| Future Direction | Description | Potential Impact |

|---|---|---|

| Biocompatibility | Development for medical use | Enhanced implant performance |

| Smart Materials | Integration of sensing capabilities | Real-time applications |

| 3D Printing | Innovative design capabilities | Customization of products |

Conclusion

In conclusion, the research advancements in stabilized zirconia powder significantly enhance its properties, making it vital for multiple industries. From improving mechanical strength to increasing thermal resistance, these developments offer measurable benefits for applications in manufacturing, biomedicine, and aerospace. By embracing these innovations, companies can enhance their product offerings and maintain a competitive edge. For tailored solutions to optimize material performance, reach out to Global Industry today. Together, we can ensure your organization harnesses the full potential of stabilized zirconia powder.

FAQ Section

Q1: What is stabilized zirconia powder used for?

Stabilized zirconia powder is widely used in various industries, including manufacturing for durable components, in biomedical applications for biocompatible implants, and in aerospace for heat-resistant parts. Its unique properties make it suitable for high-stress environments and applications requiring exceptional thermal stability.

Q2: How does research improve the properties of zirconia?

Research enhances zirconia properties through innovative methods such as advanced synthesis techniques, the incorporation of new dopants, and the development of superior processing technologies. These efforts aim to optimize mechanical strength, thermal resistance, and chemical durability, ensuring better performance in end-use applications.

Q3: Are there any limitations to stabilized zirconia materials?

Yes, while stabilized zirconia is highly effective, it does face limitations. Material degradation under extreme conditions, challenges in maintaining phase stability, and the need for adherence to various regulatory standards are ongoing concerns that researchers continuously strive to address.

Q4: Why is understanding research advances important for businesses?

Staying informed about research advancements is crucial for businesses as it allows them to adopt cutting-edge technologies and materials. This integration can lead to improved product performance, increased competitiveness in the marketplace, and the potential for innovation that meets evolving customer needs.

Q5: What future trends should industries watch for in zirconia research?

Industries should watch for trends such as the growing use of biocompatible zirconia materials in the medical field, advancements in smart materials that incorporate sensing capabilities, and the impact of 3D printing technologies on the design and manufacturing of zirconia products. These trends have the potential to revolutionize current applications and create new market opportunities.