In the realm of dental materials, understanding the key composition parameters for dental-grade zirconia powder is essential for achieving quality outcomes. Many professionals encounter challenges when selecting the right zirconia for their applications, often based on uncertain criteria or incomplete information. This article addresses those concerns by detailing the critical compositional elements that influence the performance and reliability of zirconia in dental use. With insights backed by industry standards and expert advice, we aim to empower purchasing managers and decision-makers to make well-informed choices that enhance their product offerings and patient satisfaction.

The image shows a labeled diagram of zirconia powder composition, highlighting the key components that impact its quality and performance.

What Are the Key Composition Parameters for Dental Zirconia Powder?

When evaluating dental zirconia powder, it is vital to understand its composition. The primary parameters include the proportions of zirconium oxide, yttrium oxide, and other elements that can influence the material’s properties. Each of these factors contributes uniquely to the overall characteristics of zirconia, making it essential to strike the right balance among them.

Zirconia, primarily consisting of zirconium dioxide (ZrO2), is known for its strength and durability. Zirconium oxide serves as the backbone of the material, providing exceptional mechanical properties such as high strength and fracture toughness. The addition of yttrium oxide acts as a stabilizing agent, preventing the formation of undesirable phases during processing. Typically, a range of 4.5% to 8% yttrium oxide is considered optimal for creating a tetragonal phase of zirconia, which significantly enhances its strength and stability.

In addition to zirconium and yttrium oxides, other additives are sometimes included to enhance specific qualities. These can include elements like alumina, which contributes to wear resistance, and ceria, which helps improve high-temperature stability. These additives can make zirconia more versatile for various dental applications but require careful consideration of their proportions.

To summarize, the key composition parameters for dental zirconia powder include:

- Zirconium oxide content: Determines primary strength and durability.

- Yttrium oxide proportions: Stabilizes the zirconia phase for consistent properties.

- Presence of stabilizers and additives: Enhances specific traits such as wear resistance and thermal stability.

Understanding these elements allows professionals to make educated decisions regarding material selection, ultimately improving the quality and reliability of dental restorations. As the demand for high-quality dental materials continues to grow, staying informed about these crucial parameters becomes increasingly important for dental practitioners and manufacturers alike.ection.

Why Is Particle Size Significant in Dental Zirconia?

Particle size plays a critical role in determining the mechanical properties of dental zirconia. The size of the zirconia particles affects how they sinter, which is the process of compacting and forming a solid mass without melting. Understanding the significance of particle size provides insights into optimizing the performance of zirconia in dental applications.

One key point is that smaller particles tend to enhance the surface area, thereby improving sintering efficiency. A reduced particle size can facilitate densification during the firing process, resulting in stronger and more durable dental restorations. This increased surface area allows for better bonding between the particles, leading to a more homogeneous material structure.

Moreover, smaller particles contribute to improved flowability during processing, which can enhance the uniformity of the final product. This is particularly important in techniques like 3D printing or CAD/CAM milling, where precise dimensions are crucial.

Additionally, smaller particles can help achieve better translucency, which is crucial for producing aesthetic dental solutions like crowns and bridges.

Therefore, it’s essential to consider the optimal range of particle sizes to maximize the benefits of zirconia. The recommended particle size typically falls between 100 nm to 500 nm.

Here’s a summary of the significance of particle size:

| Particle Size | Effect on Performance |

|---|---|

| 100 nm – 200 nm | Enhanced translucency and strength |

| 200 nm – 500 nm | Improved sintering and mechanical properties |

| > 500 nm | May result in reduced strength and aesthetic quality |

In essence, carefully selecting the right particle size not only optimizes the performance of dental zirconia but also directly affects the manufacturing efficiency and aesthetic outcomes.

How Do Additives Affect Zirconia’s Performance?

Additives are crucial in enhancing the performance of dental-grade zirconia. Various substances may be intentionally included in the composition to fine-tune mechanical and aesthetic properties.

For instance, alumina and ceria are common additives in zirconia formulations. Alumina can improve the wear resistance of the final product while ceria helps to enhance the material’s stability at high temperatures. Moreover, the right balance of these additives can significantly influence the final properties of the zirconia.

It’s also worth noting that the type and amount of additives can affect translucency. For example, incorporating more alumina might increase strength but can reduce the material’s transparency. Finding the ideal balance is essential to achieve the desired aesthetic outcomes.

In summary, the impact of additives includes:

- Mechanical strength enhancement

- Increased wear resistance

- Aesthetic improvements

Here’s a table that summarizes common additives and their effects:

| Additive | Type | Effect on Zirconia Performance |

|---|---|---|

| Yttrium | Stabilizer | Enhances strength and stability |

| Alumina | Reinforcement | Improves wear resistance |

| Ceria | Stabilizer | Increases thermal stability |

By understanding how additives interact with zirconia, dental professionals can tailor their material choices to suit specific applications.

What Role Does Purity Play in Zirconia Powder Quality?

Purity is paramount when evaluating zirconia powder quality, as it significantly impacts the performance and safety of dental materials. In the dental field, where precision and reliability are essential, the presence of impurities can lead to critical issues that affect both material properties and patient outcomes.

Impurities may originate from various sources, including contaminants during the manufacturing process, storage conditions, or even during handling. These undesirable substances can alter the properties of zirconia, resulting in inconsistencies that could compromise the mechanical strength and aesthetic qualities of the final product.

Maintaining high purity levels ensures that the chemical composition stays within desired parameters, bolstering the material’s strength, toughness, and biocompatibility over time. This is particularly important in applications involving dental implants and restorations, where material failure could lead to severe consequences for the patient.

To ensure high purity, various methods can be employed:

- Raw Material Selection: Choosing high-quality raw materials from reputable suppliers minimizes the introduction of contaminants.

- Manufacturing Procedures: Implementing rigorous manufacturing protocols that include cleanroom environments and controlled processing conditions can greatly reduce the risk of contamination.

- Regular Testing: Employing methods such as X-ray fluorescence (XRF) and chemical analysis helps in monitoring the purity of zirconia powder throughout the production process.

- Quality Control: Establishing comprehensive quality control measures ensures that only zirconia powders meeting the required purity standards reach the end user.

Several testing methods exist to assess purity, including X-ray fluorescence and chemical analysis. These allow manufacturers to verify that their zirconia powder meets stringent quality standards.

Here’s a brief overview of the importance of purity:

| Purity Level | Impact on Performance |

|---|---|

| High Purity | Consistent mechanical properties; biocompatible |

| Moderate Purity | Potential for variability in performance |

| Low Purity | Increased risk of failure and health issues |

Recognizing the relevance of purity can guide selections and manufacturing processes that uphold quality and safety in dental applications. Ensuring high purity levels is crucial not only for performance but also for maintaining the trust of both dental professionals and their patients in the materials used for restorative procedures.

How Important Are Processing Conditions in Powder Characteristics?

Processing conditions significantly influence the characteristics of zirconia powder, ultimately affecting the quality and performance of the final product. Several factors come into play, such as temperature, time, and the atmosphere used during processing. Each of these elements has the potential to alter the microstructure, which in turn impacts strength, translucency, and other vital qualities.

For instance, temperature is one of the most critical factors in zirconia processing. Higher temperatures can facilitate densification, which helps remove porosity and enhances mechanical strength. However, excessive heat can also provoke phase transformations that lead to brittleness or weaken the material structure. Therefore, it’s crucial to find an optimal temperature range that promotes the desired physical properties without introducing defects.

Time during processing is another key consideration. The duration of heat application impacts not only the densification but also the grain growth within the powder. Longer sintering times can lead to coarsening of the grain structure, which might reduce the overall strength of the zirconia.

The atmosphere in which zirconia is processed also plays a significant role. Ideally, a controlled environment—such as a neutral gas atmosphere—should be maintained to prevent oxidation and other detrimental reactions that might alter the material’s chemical composition.

To ensure quality and reproducibility, manufacturers should adhere to the following practices regarding processing conditions:

- Monitor Temperature: Maintain consistent and optimal temperature levels during processing to enhance strength and prevent phase changes.

- Control Processing Time: Adjust sintering time to balance densification and grain growth, ensuring robust mechanical properties.

- Optimize Atmospheric Conditions: Utilize controlled environments to reduce the risk of chemical reactions that could compromise zirconia integrity.

- Implement Quality Checks: Regular testing throughout the processing stages to detect any variations in properties early on.

By maintaining strict control over these processing parameters, manufacturers can create zirconia products that meet high standards in both aesthetics and performance, ensuring reliability in dental applications.rocessing conditions, manufacturers can enhance the performance and reliability of dental zirconia.

What Testing Methods Gauge Zirconia Powder Quality?

Assessing the quality of zirconia powder requires rigorous testing methods to ensure that the material meets the necessary standards for dental applications.

Several standard tests can evaluate various properties. Mechanical strength tests, such as flexural strength and fracture toughness, provide insights into how zirconia performs under stress.

Translucency measurements are critical, especially for applications requiring aesthetic outcomes. The degree of light transmission can significantly affect the visual appeal of dental restorations.

Comprehensive testing should encompass a variety of factors to provide a rounded view of quality.

Key testing methods include:

| Test Type | Purpose |

|---|---|

| Flexural Strength Test | Evaluates material strength under load |

| Fracture Toughness Test | Assesses resistance to cracking |

| Translucency Measurement | Determines degree of light penetration |

Utilizing these tests enables manufacturers to ensure the quality of their zirconia powder aligns with clinical expectations.

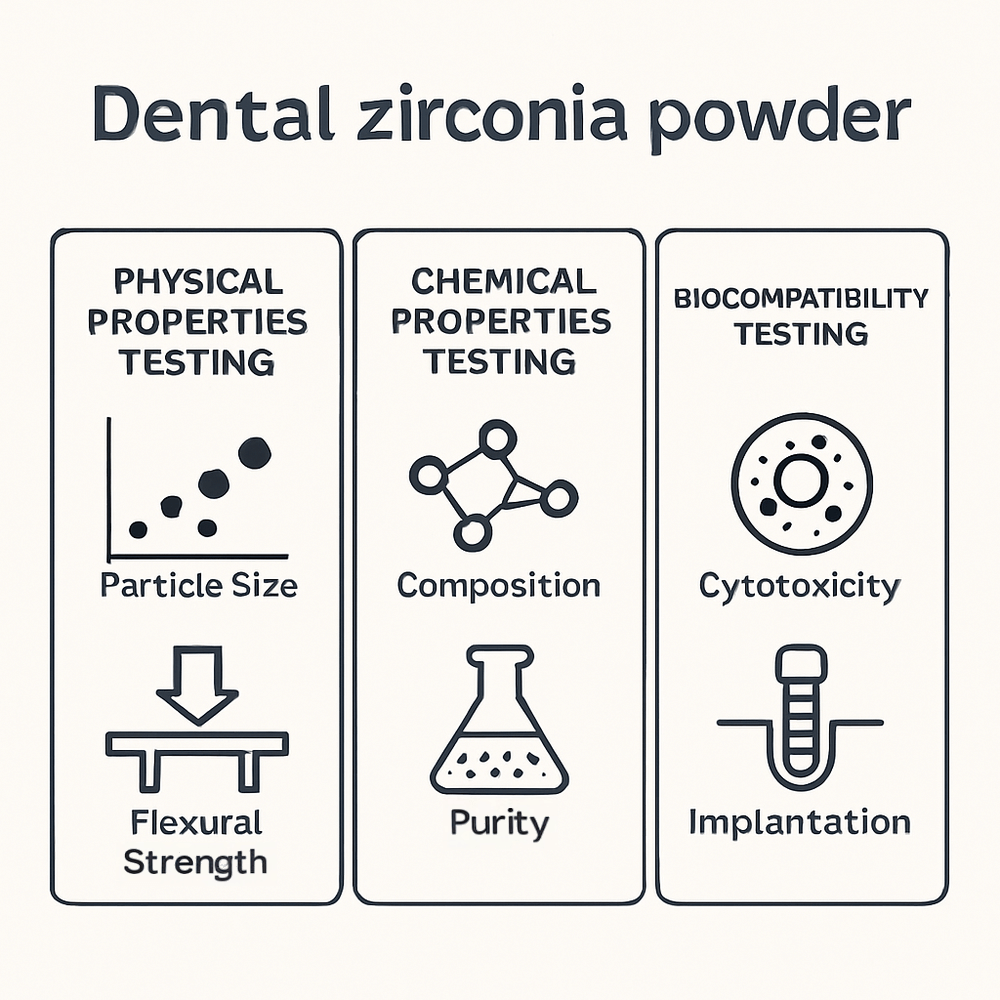

This image illustrates various testing methods used to assess the quality and performance of dental zirconia powder.

How Can You Ensure Consistency in Zirconia Production?

Consistency in zirconia production is vital for achieving uniform performance across various dental applications. Variability can arise from numerous factors, including raw materials, processing techniques, and environmental conditions.

To mitigate these variations, implementing strict quality control measures is essential. Regular monitoring of production parameters, raw material quality assessments, and ongoing product testing should be standard practice. Additionally, it’s important to adopt a proactive approach to identify potential issues before they escalate.

Some effective strategies to ensure consistency include:

- Standard Operating Procedures (SOPs): Develop detailed SOPs for each step of the production process. This will provide clear guidelines for employees to follow, reducing the risk of human error.

- Supplier Validation: Ensure that raw materials meet stringent quality standards. Establishing strong relationships with reliable suppliers can help maintain a consistent supply of high-quality materials.

- Batch Testing: Conduct regular testing of each production batch. This can include mechanical property tests, purity assessments, and performance evaluations to confirm that products meet required specifications.

- Process Control: Implement statistical process control (SPC) methods to monitor production conditions in real time. This allows for timely adjustments to maintain consistent output.

- Training and Development: Provide ongoing training for staff involved in the production process. Well-trained personnel can better follow processes and identify potential outliers during production.

- Environmental Controls: Maintain consistent environmental conditions in production facilities. Factors like temperature and humidity can significantly impact the characteristics of zirconia.

Focusing on these strategies allows for reliable production processes that enhance trust in zirconia products. By consistently implementing these measures, manufacturers can ensure that their zirconia powder meets high-quality standards, ultimately leading to better patient outcomes and satisfaction in dental applications.

What Innovations Are Emerging in Zirconia Powder Technology?

Innovations in zirconia powder technology continue to shape dental applications. Advanced manufacturing techniques, new formulations, and improved processing methods are all contributing to enhanced performance.

For example, the introduction of CAD/CAM technology has revolutionized the way zirconia is used in dentistry. This allows for precise milling and reduces material waste, making the production process more efficient.

Research into bioactive zirconia is also underway, aiming to improve compatibility with biological tissues. These innovations pave the way for better patient outcomes and broaden the uses of zirconia in dental treatments.

As the industry evolves, staying informed about emerging technologies is crucial for all stakeholders.

Here’s a brief overview of recent innovations:

| Innovation | Description |

|---|---|

| CAD/CAM Techniques | Enhances precision and reduces waste |

| Bioactive Zirconia | Improves compatibility with biological tissues |

| Advanced Processing | Increases efficiency and performance benefits |

Embracing these innovations can lead to significant improvements in dental practices and patient care.

How Do Regulatory Standards Influence Zirconia Use in Dentistry?

Regulatory standards play a crucial role in ensuring the safe use of zirconia in dental applications. Various organizations, such as the ISO and FDA, establish guidelines that dictate acceptable levels of quality and safety.

These regulations help manufacturers ensure that their products meet high-performance standards. Complying with these requirements fosters confidence among dental professionals and patients, enhancing trust in the materials used for dental restorations.

Understanding these standards is vital for manufacturers. They dictate choices related to raw materials, processing methods, and quality assurance measures.

Here’s an overview of the impact of regulatory standards:

| Regulatory Body | Focus Area |

|---|---|

| ISO | Establishes international quality standards |

| FDA | Regulates medical and dental products for safety |

| Local Authorities | Enforce compliance with regulations in specific regions |

Navigating these regulations not only ensures compliance but also promotes excellence in product offerings.

What Are Common Challenges in Working with Zirconia Powder?

While zirconia is highly valued in dentistry, various challenges can arise in its usage. One common issue is managing the material’s brittleness, which can lead to fractures if not handled correctly.

Another challenge is achieving the desired translucency, which requires precise control over processing conditions and material additives.

Manufacturers and dental professionals must also stay vigilant about contamination during production and handling processes.

Implementing best practices in managing these challenges is essential for ensuring reliable and high-quality outcomes.

Here’s a summary of common challenges:

| Challenge | Solution |

|---|---|

| Brittleness | Employ careful handling techniques |

| Maintaining Translucency | Control processing conditions and additives |

| Contamination | Adhere to strict hygiene and handling protocols |

By being aware of these challenges and applying effective solutions, dental practitioners can enhance the quality and performance of zirconia applications.

Conclusion

In this article, we explored the essential composition parameters and practical insights concerning dental zirconia powder. Readers learned how factors like particle size, purity, and processing conditions play significant roles in the performance and reliability of the material. The key takeaway here is that investing in high-quality zirconia can lead to superior dental restorations and satisfied patients. To further optimize your material choices, consider engaging with Global Industry for tailored assistance and resources in navigating your supply options.

FAQ Section

Q1: What specific parameters are crucial for zirconia powder?

Critical parameters for zirconia powder include particle size, which influences strength and translucency; the ratio of zirconium oxide to stabilizers like yttria; and purity levels, which affect biocompatibility and mechanical performance. Understanding these parameters is essential for selecting high-quality zirconia that meets clinical needs.

Q2: How does particle size influence zirconia powder performance?

Particle size affects not only the mechanical properties of zirconia but also its sintering behavior. Smaller particles provide a larger surface area for better densification during firing, leading to increased strength and improved aesthetics. Conversely, larger particles may result in reduced strength and less desirable translucency, impacting the overall look of dental restorations.

Q3: What additives are commonly used in zirconia formulations?

Common additives in zirconia formulations include yttrium oxide, which stabilizes the material and improves strength, and alumina, which enhances wear resistance and toughness. Some formulations may also include cerium oxide to improve thermal stability. The careful balance of these additives can optimize the performance characteristics required for specific dental applications.

Q4: How can manufacturers ensure the quality of zirconia powder?

Manufacturers can ensure the quality of zirconia powder by implementing stringent quality control measures, such as regular testing for mechanical properties, purity, and particle size distribution. Utilizing standardized processing techniques helps maintain consistency between batches, ensuring that each product meets the necessary regulatory standards for dental applications.

Q5: What innovations are shaping the future of zirconia powder?

Emerging innovations in zirconia powder technology include advancements in CAD/CAM manufacturing techniques that enhance precision and reduce waste, as well as the development of bioactive zirconia that improves the interaction with surrounding biological tissues. Additionally, research is ongoing into new formulations that offer improved properties, such as increased strength and enhanced esthetics, paving the way for more versatile applications in dentistry.