The logistics of transporting zircon powder are complex and can significantly impact costs for businesses in this industry. Many buyers struggle to navigate the various factors that influence transportation costs, and often they are unsure about how to optimize these expenses. This article addresses the major logistics challenges associated with zircon powder transportation, providing solutions that can lead to cost savings and efficiency improvements. With insights drawn from industry expertise, we aim to equip you with practical strategies to enhance your logistics operations.

What Factors Influence Zircon Powder Logistics Costs?

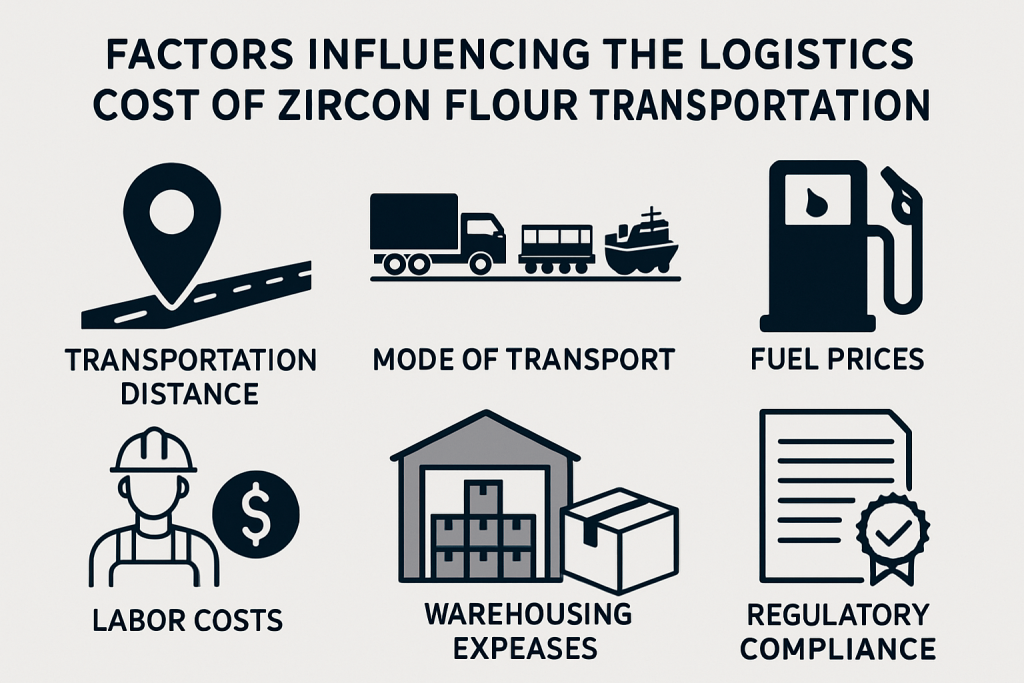

Several factors affect the logistics costs associated with transporting zircon powder. Understanding these can help businesses make informed decisions.

Firstly, the nature of zircon powder itself plays a role. The product requires specific handling and transportation methods to prevent contamination and ensure quality.

Next, the cost of transportation is affected by distance. Longer distances typically mean higher transportation costs. However, the choice of route can also influence expenses. A direct route may reduce costs, while a longer but easier route can save on handling fees.

Packaging is another critical factor. Effective packaging protects the product during transit and can prevent loss or damage. The costs associated with packaging materials must be factored into the overall logistics expenses.

Lastly, labor costs for loading and unloading zircon powder are significant, especially if specialized equipment or trained personnel are required. Businesses can reduce these costs by optimizing their operational processes.

Understanding these factors can provide businesses with a foundation for reducing transportation costs and improving overall logistics efficiency.

This image illustrates key factors that affect logistics costs for transporting zircon powder.

How Does Packaging Impact Transportation Expenses?

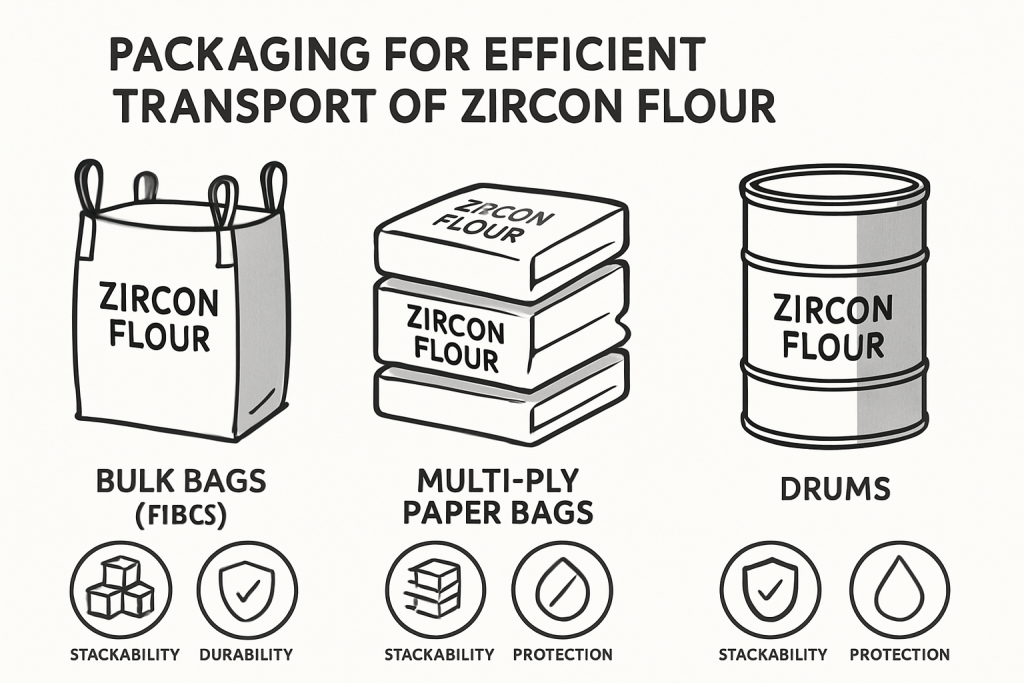

Packaging has a significant effect on the transportation of zircon powder. The right packaging protects the product and can also optimize logistics costs.

Firstly, effective packaging ensures the integrity of the zircon powder during transport. Quality packaging minimizes contamination and the risk of spillage, which can lead to product loss.

Different packaging options are available for zircon powder, such as bulk bags, drums, or sealed containers. Each type carries its own benefits and costs. For instance, bulk bags might be cost-effective for large shipments but require more care in handling. On the other hand, smaller sealed containers offer better product protection but add to the logistics expenses.

While higher quality packaging might incur initial costs, it can lead to long-term savings by reducing damage and waste. Businesses should consider these factors when selecting packaging solutions. In short, investing in the right packaging can be a smart decision that pays off over time.

Here is a comparison of packaging options for zircon powder:

| Packaging Type | Advantages | Disadvantages |

|---|---|---|

| Bulk Bags | Cost-effective, easy to handle | Risk of contamination, spills |

| Drums | Good protection, stackable | Higher initial costs |

| Sealed Containers | Excellent protection, reduces waste | More costly, requires more space |

This image presents various packaging types suitable for transporting zircon powder efficiently.

3. What Role Does Transportation Mode Play?

The choice of transportation mode significantly impacts zircon powder logistics costs. Each mode has its own strengths, weaknesses, and associated costs.

For example, road transport is typically flexible and can reach remote locations. However, it often incurs higher fuel and labor costs. Conversely, rail transport is more economical for long distances and large volumes, though it may lack flexibility in pickup and delivery points.

Air transport offers speed, which can be crucial in urgent situations, yet it is the most costly option. Businesses must weigh the urgency of the shipment against the associated costs.

It’s also essential to consider multi-modal transportation solutions, which can optimize overall logistics efficiency. These solutions combine different transport modes while managing costs effectively.

In evaluating transportation costs, businesses should analyze specific needs, distance, and urgency to select the most suitable mode. Ultimately, making informed decisions on transportation can lead to significant savings.

| Mode | Cost | Speed | Flexibility | Capacity |

|---|---|---|---|---|

| Road | High | Medium | High | Medium |

| Rail | Medium | Low | Medium | High |

| Air | High | Very High | Low | Low |

4. How Do Regulatory Compliance Requirements Affect Costs?

Regulatory compliance is a critical aspect of transporting zircon powder. It involves adhering to local, national, and international regulations, which can impact logistics costs significantly.

Transporting hazardous materials often requires special certifications and compliance with safety standards. Failure to meet these regulations can result in costly penalties or delays that may disrupt operations.

Additionally, the process of obtaining necessary permits and adhering to safety protocols can add to labor costs. Businesses should invest in understanding all regulatory requirements relevant to zircon powder transport. Having a knowledgeable compliance team can help minimize costly mistakes and ensure smooth operations.

Programmatic solutions can also play a role. For example, companies can utilize software designed to track compliance requirements and streamline the necessary documentation process.

Effective management of compliance can lead to lower costs and a more reliable logistics operation:

| Compliance Aspect | Potential Costs | Impact on Logistics |

|---|---|---|

| Permits | Application fees | Delays if not obtained timely |

| Safety Training | Employee training costs | Improves safety, reduces risk |

| Documentation | Administrative costs | Essential for tracking shipments |

5. What Supply Chain Management Strategies Optimize Costs?

Optimizing supply chain management is essential for improving logistics in zircon powder transport. Successful strategies can lead to reduced costs and enhanced efficiency.

One solid strategy involves enhancing communication across the supply chain. Utilizing technology, such as inventory management systems, can help keep all parties informed. This real-time visibility can prevent overstocking or stockouts.

Another approach is to build strong relationships with suppliers and transportation partners. Good relationships can lead to better service, more favorable rates, and increased flexibility in operations.

Strategically planning inventory levels is also vital. Keeping just enough stock reduces holding costs while ensuring that products are available when needed. Adopting these strategies can significantly improve overall logistics efficiency.

Key supply chain management strategies include:

● Regular Evaluations: Assess processes to identify areas for improvement.

● Enhancing Communication: Improve collaboration between suppliers and logistics partners.

● Building Relationships: Foster long-term partnerships for better rates and service.

● Inventory Management: Use just-in-time strategies to optimize stock levels.

● Adopting Technology: Implement systems for tracking and visibility.

To illustrate effective supply chain management, here are key strategies and their benefits:

| Strategy | Benefits |

|---|---|

| Strong Communication | Streamlines operations, prevents errors |

| Building Relationships | Better service, favorable terms |

| Inventory Level Planning | Reduces holding costs, ensures availability |

6. How Can Route Planning Reduce Transportation Costs?

Efficient route planning is a crucial factor in reducing transportation costs. A well-planned route can lead to significant savings in time and resources.

Utilizing technology, such as GPS and route optimization software, allows businesses to find the most efficient paths for transportation. These tools can help avoid traffic, minimize fuel expenses, and reduce wear and tear on vehicles.

Additionally, analyzing historical data regarding traffic patterns and delivery times can inform better route planning. Incorporating these elements into logistics operations can result in faster deliveries and lower operational costs.

Here’s a summary of effective route planning benefits:

| Benefit | Impact |

|---|---|

| Reduced Fuel Costs | Significant savings over time |

| Increased Delivery Efficiency | Enhances customer satisfaction |

| Lower Vehicle Maintenance | Prolongs vehicle lifespan |

This image showcases the importance of route planning in reducing logistics costs effectively.

7. What Are Common Risks in Zircon Powder Transportation?

Transportation of zircon powder carries inherent risks that businesses must account for. Recognizing and mitigating these risks can prevent costly disruptions.

Common risks include product damage from improper handling, delays caused by unforeseen circumstances, and theft during transit. Each of these can lead to increased costs and operational inefficiencies.

Implementing safety protocols and providing staff training can reduce the likelihood of damage. Additionally, businesses should consider purchasing insurance to cover potential losses due to theft or delay. Taking proactive measures can lead to more reliable operations and substantial savings.

Here’s a list of common risks in zircon powder transportation:

● Market Fluctuations: Changing demand may affect pricing.

● Product Damage: Improper handling can lead to loss.

● Delivery Delays: Unforeseen circumstances can interrupt schedules.

● Theft: Transportation may expose shipments to risks.

● Regulatory Issues: Non-compliance can result in penalties.

A summary of common risks and mitigation strategies is outlined below:

| Risk | Mitigation Strategy |

|---|---|

| Product Damage | Proper training and handling procedures |

| Delivery Delays | Real-time tracking systems |

| Theft | Insurance and secure transport methods |

8. How Can Technology Enhance Logistics Efficiency?

Technology plays a vital role in optimizing logistics efficiency for transporting zircon powder. By leveraging various technologies, companies can enhance operations and reduce costs.

For example, tracking systems provide real-time data on shipments, helping companies respond to issues proactively. Furthermore, inventory management software can streamline stock control, leading to more efficient operations.

Automating routine tasks can also help reduce labor costs and minimize human error. Adopting these technologies allows organizations to focus on core operations while enhancing efficiency.

Here’s a summary of technology solutions and their benefits:

| Technology | Benefit |

|---|---|

| Real-Time Tracking Systems | Improved visibility and responsiveness |

| Inventory Management Software | Streamlined stock control |

| Automation Tools | Reduced labor costs, minimized errors |

9. What Are the Impacts of Market Trends on Costs?

Market trends can significantly influence logistics costs associated with zircon powder transport. Understanding and adapting to these trends is crucial for businesses.

For instance, fluctuations in fuel prices can directly impact transportation costs. As fuel prices rise, so do the costs for transporting goods. Additionally, changes in demand for zircon powder can affect shipping volume and pricing strategies.

Keeping an eye on industry trends enables businesses to adjust logistics strategies proactively. Proactive adaptation to market conditions helps in maintaining competitiveness and controlling costs.

Here are some current market trends to watch:

● Regulatory Changes: Keep updated on compliance requirements.

● Fuel Price Volatility: Regularly monitor for sudden rises.

● Demand Shifts: Stay flexible to adjust supply levels.

● Technological Advancements: Adopt new tools for efficiency.

● Sustainability Trends: Focus on eco-friendly practices.

A summary of market trends and their potential impacts is as follows:

| Trend | Impact on Costs |

|---|---|

| Fuel Price Fluctuations | Increased transport costs |

| Demand Shifts | Changes in shipping volume and pricing |

10. What Best Practices Improve Overall Logistics Performance?

Implementing best practices is key to enhancing logistics performance in zircon powder transport. These practices enable companies to improve efficiency while minimizing costs.

First, regular evaluations of logistics performance can highlight areas for improvement. Using metrics like shipping times and costs helps businesses to analyze their operations critically.

Training employees on best practices in handling and transport can also yield significant results. A well-informed workforce enhances overall operations and reduces errors.

Incorporating these best practices not only streamlines logistics but also bolsters overall business performance.

Here’s a list of best practices for logistics performance:

● Implement Safety Protocols: Minimize risks and protect products.

● Regular Performance Evaluations: Identify areas for improvement.

● Training: Enhance operational knowledge.

● Utilize Technology: Streamline processes and improve communication.

● Optimize Inventory Levels: Balance stock to reduce costs.

In conclusion, understanding the logistics challenges related to transporting zircon powder empowers businesses to make informed decisions. By strategically managing costs, optimizing operations, and leveraging technology, you can reduce expenses and improve overall efficiency. If you want to enhance your logistics capabilities, partner with Global Industry for expert guidance. Visit our website for resources and support on optimizing your logistics processes.

FAQ Section

Q1: What determines the transportation costs of zircon powder?

Transportation costs for zircon powder are influenced by several factors. Key elements include the packaging type, which affects handling and shipping methods, and the chosen transportation mode, such as road, rail, or air, each of which carries different cost implications. Additionally, the distance between the origin and destination is a crucial factor, as longer routes typically incur higher fuel and operational costs. Regulatory compliance, including permits and safety certifications, can also add to the expenses involved in transporting zircon powder. Lastly, market conditions such as fuel prices and demand fluctuations further impact the overall transportation costs.

Q2: How can I ensure compliance when transporting zircon powder?

Ensuring compliance when transporting zircon powder requires a thorough understanding of both local and international regulations regarding hazardous materials. Businesses should start by conducting a detailed review of all applicable laws related to the classification, handling, and transportation of zircon powder. This often includes obtaining necessary permits and certifications for transportation. Regular training for employees on compliance procedures is essential to maintaining safety standards and avoiding penalties. Additionally, implementing a compliance management system can help track relevant regulations, manage documentation, and ensure that all transportation activities adhere to current legal requirements, thereby minimizing risks associated with non-compliance.

Q3: What packaging options are available for zircon powder?

Various packaging options are available for zircon powder, each designed to meet specific logistical and handling requirements. Common choices include bulk bags, which are cost-effective for large volumes, but require careful handling to prevent contamination. Drums are another option, offering better protection against damage and spillage but often at a higher cost and increased weight. Sealed containers provide excellent protection from environmental factors but can be more expensive and require additional space for storage. Each packaging type should be selected based on factors such as shipping volume, transport method, and the specific handling requirements of zircon powder to ensure the product’s integrity throughout the transportation process.

Q4: How does route planning affect logistics costs?

Effective route planning plays a crucial role in logistics costs by optimizing travel distance, fuel consumption, and delivery timelines. Utilizing route optimization software can help identify the most efficient paths for transporting zircon powder, reducing both fuel expenses and transit times. By considering factors such as traffic patterns, road conditions, and delivery windows, businesses can avoid delays and unexpected costs. Moreover, strategic route planning can minimize wear and tear on vehicles, leading to lower maintenance costs in the long run. Overall, well-planned logistics routes are vital for maintaining operational efficiency and delivering products on time while keeping transportation costs in check.

Q5: What technology solutions can optimize the logistics process?

Technology solutions are essential for optimizing logistics processes in zircon powder transportation. Implementing real-time tracking systems enables businesses to monitor shipments and respond swiftly to any issues that arise during transit, thus improving overall visibility. Inventory management software allows companies to keep accurate track of stock levels, helping to prevent both overstocking and stockouts. Automating routine logistics tasks can reduce labor costs and mitigate human errors. Additionally, adopting advanced data analytics can provide insights into logistics performance, enabling managers to make informed decisions for future operations. By leveraging technology, businesses can streamline their logistics processes, reduce costs, and enhance service quality.