Proper storage of zircon powder during international transit is a significant concern for businesses involved in its supply chain. The quality of zircon powder can degrade if not handled properly, leading to financial losses and client dissatisfaction. This article provides solutions to maintaining high-quality zircon powder throughout the transportation process. By following best practices in storage and handling, companies can ensure that their zircon remains in optimal condition. With insights based on industry standards and practical advice, this article aims to establish credibility and offer you the tools necessary to manage your zircon powder effectively.

How Do Storage Conditions Affect Zircon Powder Quality?

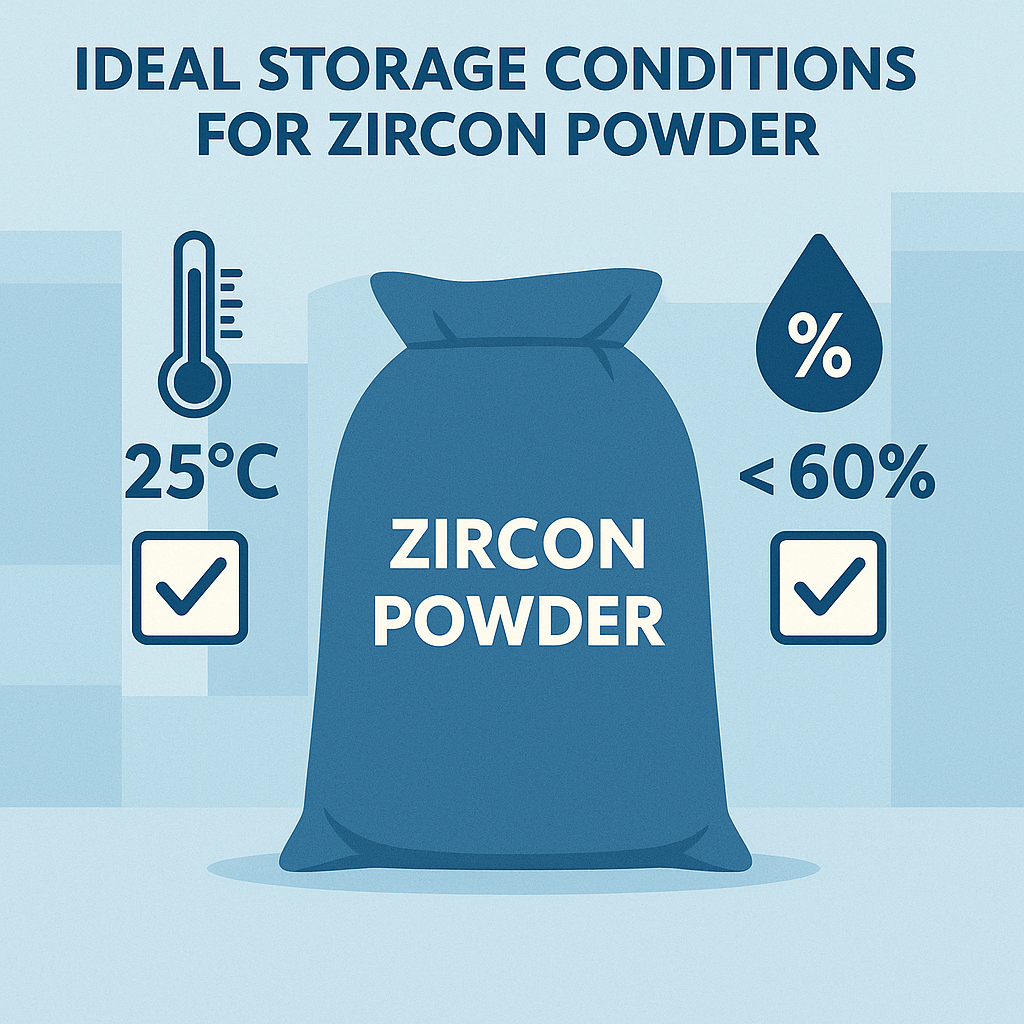

The storage conditions for zircon powder play a crucial role in maintaining its quality. Temperature, humidity, and light exposure are all key factors that can impact its integrity.

First, let’s discuss temperature. Zircon powder should be stored at a consistent, moderate temperature. If the temperature fluctuates significantly, it can cause the powder to clump or degrade. A suitable range is generally between 10°C and 25°C.

Next up is humidity. High humidity can lead to moisture absorption, which may alter the chemical properties of the zircon. Ideally, storage areas should maintain humidity levels below 50%, preventing the formation of lumps.

Lastly, light exposure can cause chemical reactions in zircon powder. To mitigate this, always store zircon in opaque containers or in dark environments. Keeping the storage area free from direct sunlight is also critical.

This attention to storage conditions can prevent the deterioration of zircon powder and ensure its quality when it reaches its destination.

This image depicts the ideal conditions for storing zircon powder, focusing on temperature and humidity control.

What Packaging Solutions Ensure Zircon Powder Integrity?

Effective packaging is pivotal for preserving zircon powder during transit. Using the right materials and techniques can greatly enhance its protection against external factors.

First, consider the type of packaging material. Moisture-resistant materials like polyethylene or vacuum-sealed bags are ideal for keeping zircon powder dry. Using multi-layer packaging adds an extra layer of defense against environmental factors.

Next, it’s essential to focus on sealing techniques. Strong sealing mechanisms ensure that no interior moisture can leak in. Proper sealing not only protects the quality of the zircon but also enhances its shelf life by avoiding contamination.

Another crucial aspect is the inclusion of cushioning within the outer packaging. Cushioning material absorbs shocks and vibrations encountered during transit, preventing the powder from breaking down. Think about using bubble wrap or foam padding to protect your shipment.

Using these packaging solutions can significantly reduce the risk of quality loss during transportation.

| Packaging Type | Advantages | Disadvantages |

|---|---|---|

| Polyethylene Bags | Lightweight, resistant to moisture | May not be puncture-proof |

| Vacuum-Sealed Bags | Excellent at keeping oxygen and moisture out | Requires sealing equipment |

| Multi-layer Cartons | Great for added protection against shocks | Bulkier than other options |

| Opaque Containers | Protects from light exposure | Can be heavier and costlier |

This image illustrates various packaging solutions for zircon powder, highlighting moisture resistance and cushioning methods.

Which International Regulations Govern Zircon Transit?

Shipping zircon powder internationally involves various regulations that businesses must comply with. Understanding these regulations is vital to avoid legal issues and ensure smooth transit.

First, each country has its own rules regarding the import and export of chemical substances. Familiarizing yourself with these regulations is a must. Consulting with a logistics expert can help identify any specific requirements.

Documentation is another critical aspect. Ensure you prepare all necessary paperwork, such as safety data sheets (SDS), customs declarations, and commercial invoices. These documents not only facilitate smoother customs processing but also safeguard against potential fines.

Moreover, penalties for non-compliance can be severe, including hefty fines or shipment delays. Therefore, it is essential to stay informed about the international regulations governing zircon transportation. Being proactive in understanding these rules can save you time and resources.

| Document | Purpose |

|---|---|

| Safety Data Sheet (SDS) | Details hazards and safe handling procedures |

| Customs Declaration | Required for clearing goods through customs |

| Commercial Invoice | Lists goods being shipped and verifies their value |

What Transportation Methods Are Most Suitable for Zircon Powder?

Choosing the right transportation method for zircon powder can significantly affect its integrity. Each option presents both advantages and disadvantages that companies must evaluate.

Air transport is fast, reducing the time zircon powder is in transit. However, it can be more expensive and may have stricter regulations regarding packaging and documentation.

Sea freight is a more economical option, especially for bulk shipments. Nonetheless, shipping by sea takes longer and exposes the product to potential humidity issues during transit. More robust packaging is necessary for this method.

Land transport, while convenient for short distances, can pose risks of physical damages from road conditions. It remains affordable and effective for regions with reliable infrastructure.

When selecting a transportation method, always consider the balance between costs, speed, and safety. Each option has its merits, and the best choice will depend on your specific needs.

| Transportation Method | Advantages | Disadvantages |

|---|---|---|

| Air | Fast delivery | Higher costs |

| Sea | Economical for bulk shipments | Longer transit times |

| Land | Affordable and accessible | Vulnerable to local conditions |

How Can You Monitor Storage Conditions During Transit?

Monitoring the storage conditions of zircon powder while in transit is vital for quality assurance. Implementing modern technologies can significantly aid this process.

Real-time condition monitoring systems allow you to track temperature and humidity throughout the journey. Such technology can alert you immediately if environmental conditions shift outside your set parameters.

Data loggers are another useful tool. These devices record temperature and humidity data at regular intervals, creating a detailed log you can review upon delivery. They are particularly helpful for ensuring compliance with regulations.

Additionally, consider using simple moisture indicators that change color if humidity becomes too high. While more basic, they serve as a quick visual check.

By taking these steps, businesses can better manage the integrity of zircon powder during shipping, leading to more reliable product quality.

| Monitoring Tool | Purpose |

|---|---|

| Real-time Monitoring System | Tracks conditions and sends alerts for immediate action |

| Data Loggers | Records conditions over time for review upon delivery |

| Moisture Indicator | Provides a quick visual check on humidity levels |

What Are Common Risks During Transportation of Zircon Powder?

Recognizing risks is the first step in mitigating potential problems during zircon powder transport. Several hazards can compromise the quality during transit.

Physical damage is a major risk. Rough handling or poor packaging can lead to clumping or breakage. Employing proper cushioning techniques can help prevent this.

Contamination is another concern. Improper sealing may expose the powder to irritants like dust or moisture, affecting its quality. Always ensure packaging is intact before shipment.

Regulatory non-compliance can also pose serious risks. Failing to meet legal requirements can result in fines or shipment delays. Understanding and adhering to these regulations from the outset is crucial.

Finally, transportation itself carries inherent risks. Weather events or other disasters can disrupt timelines and damage shipments. It is wise to consider insurance options to protect against such incidents.

| Common Risk | Mitigation Strategy |

|---|---|

| Physical Damage | Use adequate cushioning and durable packaging |

| Contamination | Ensure proper sealing and use high-quality packing materials |

| Regulatory Non-Compliance | Stay informed about requirements and prepare necessary documents |

This image emphasizes risk management strategies for transporting zircon powder, highlighting safety measures and protocols.

How Does Storage Duration Impact Zircon Powder Quality?

The length of time zircon powder is stored can greatly affect its quality. Understanding shelf life and maintaining the right conditions are vital.

Generally, zircon powder has a long shelf life when stored correctly. However, it can deteriorate more quickly if conditions are not optimal. For instance, prolonged exposure to humidity can lead to clumping.

Monitoring for signs of deterioration is essential. Keep an eye out for any changes in texture or color, as these may indicate degraded quality. If you notice any alterations, reconsider how you are storing the product.

Companies should also establish recommended storage durations for their products. Regularly rotating inventory helps maintain quality and ensures older stock is used first.

By managing storage duration effectively, businesses can preserve the quality of zircon powder even during extended periods in storage.

What Best Practices Should Be Implemented for Handling?

Proper handling of zircon powder is crucial for maintaining its quality. Following specific best practices ensures that the product remains uncontaminated.

First, training staff who manage the handling of zircon is vital. They should understand the sensitive nature of the product and receive guidance on safe and effective handling techniques.

Secondly, strict adherence to labeling is necessary. Clear labeling helps staff identify the contents and understand any specific handling requirements associated with the material.

Finally, establish protocols for both incoming and outgoing shipments. These protocols should outline checks to ensure the quality of zircon is not compromised at any stage of the supply chain.

Implementing these best practices can lead to continuous quality assurance and increased customer satisfaction.

| Best Practice | Description |

|---|---|

| Staff Training | Provides knowledge on safe handling procedures |

| Clear Labeling | Helps identify contents and handling requirements |

| Protocols for Shipments | Ensures quality checks are performed during transportation |

How Can You Maintain Consistency Across Multiple Shipments?

Maintaining consistency in the quality of zircon powder across shipments is essential for building trust with customers. Several strategies can help achieve reliable quality.

Establishing standard procedures for packing and storage is a critical first step. Everyone involved in the shipping process should follow these guidelines consistently.

Next, implementing quality control checks means that you can assess each batch before it departs. Regular inspections help identify issues early, allowing for corrections.

Creating feedback loops for continuous improvement is also advisable. Encourage feedback from partners and customers regarding quality. Using this information can drive enhancements in your processes.

By prioritizing consistency in quality, businesses can cultivate lasting relationships with clients and enhance their reputation in the industry.

| Consistency Strategy | Benefit |

|---|---|

| Standard Procedures | Ensures uniformity in packing and handling |

| Quality Control Checks | Identifies issues before products are shipped |

| Feedback Loops | Facilitates continuous improvements based on real-world data |

Why Is Quality Control Critical for Zircon Powder?

Quality control is a non-negotiable element in the transport of zircon powder. It influences product performance and helps meet industry standards.

First, having clear quality benchmarks ensures that every shipment meets or exceeds expectations. This involves detailed testing of each batch to ensure they align with specifications.

Moreover, a process for conducting regular quality assessments can identify potential failures early. Implementing a matrix for tracking quality over time allows you to identify trends and make necessary adjustments.

Furthermore, the impact of quality variability can extend to stakeholders, affecting their trust and future business. Ensuring reliability fosters stronger relationships with customers and encourages repeat business.

In summary, focusing on quality control throughout the transportation process leads to enhanced customer satisfaction and loyalty, ultimately benefiting your bottom line.

| Quality Control Aspect | Impact |

|---|---|

| Clear Benchmarks | Provides clear expectations for product performance |

| Regular Assessments | Identifies opportunities for process improvements |

| Reliability for Stakeholders | Builds trust and encourages repeat business |

Conclusion

In summary, maintaining the quality of zircon powder during transit requires diligent attention to various factors. From implementing optimal storage conditions to utilizing effective packaging, every step is crucial. A significant benefit of these best practices is the enhanced reliability and satisfaction experienced by your customers. If you’re looking for tailored solutions to manage your zircon powder, consider partnering with Global Industry for expert guidance and resources. Together, we can ensure that your products arrive in perfect condition.

FAQ Section

Q1: What are the ideal storage conditions for zircon powder?

The ideal storage conditions involve maintaining a consistent temperature between 10°C and 25°C and keeping humidity levels below 50%. These factors help prevent clumping and deterioration.

Q2: Which packaging materials are best for transporting zircon powder?

High-quality, moisture-resistant materials like polyethylene bags or vacuum-sealed containers offer optimal protection during transportation. This prevents exposure to moisture that can affect quality.

Q3: What regulations should I be aware of for shipping zircon internationally?

Familiarity with global shipping regulations and obtaining the necessary export documentation is critical to ensure compliance. This helps avoid legal issues and ensures smooth transit.

Q4: How can technology help in monitoring zircon powder conditions during transit?

Utilizing IoT devices for real-time monitoring and data loggers can help track temperature and humidity effectively during transit. This ensures that products remain within optimal conditions while shipping.

Q5: What risks should I consider when shipping zircon powder?

Potential risks include physical damage, contamination, and regulatory compliance issues; mitigating these risks is essential for successful transit. Establishing robust handling and shipping protocols can minimize these risks effectively.