Businesses sourcing zircon powder face a critical challenge: ensuring incoming material consistently meets stringent international quality benchmarks. Inconsistent material can lead to significant production issues, costly rework, and compromised final product performance. This challenge is particularly acute for purchasing managers and technical leads who must guarantee material integrity in a competitive market. This article provides a clear framework for understanding and implementing robust testing methodologies. It outlines essential analytical techniques and compliance requirements. Global Industry, a leader in material science solutions, offers proven expertise in verifying industrial raw material specifications. Our insights stem from years of collaboration with global manufacturers.

Understanding Zircon Powder Quality

For international buyers, a clear understanding of what defines high-quality zircon powder is the first step in successful sourcing. This involves not only an awareness of the material’s fundamental properties but also an understanding of how these properties translate into practical applications.

Fundamental Properties of High-Quality Zircon Powder:

● Particle Size Distribution: High-quality zircon powder is characterized by a precise particle size distribution. A consistent and narrow particle size distribution is crucial, especially in applications like advanced ceramics, where uniformity in size ensures even shrinkage during firing. Any deviations can lead to defects, cracking, or inconsistencies in the final product. For instance, in the manufacturing of dental ceramics, a homogeneous particle size allows for smoother surfaces and enhanced aesthetic qualities.

● Density: The density of zircon powder directly impacts its packing behavior and the final density of the sintered product. Higher density materials are often preferred in applications that demand durability and mechanical strength, such as refractory products. For example, in metal casting processes, a denser zircon powder can improve the strength and thermal conductivity of the mold, resulting in better casting outcomes.

● Purity: While physical characteristics are critical, the chemical composition of zircon powder is equally vital. The primary component, zirconium silicate (ZrSiO4), should have a high percentage to ensure purity. Impurities, even in trace amounts, can lead to significant performance issues, particularly in high-temperature environments. For example, iron oxide (Fe2O3) can introduce unwanted color variations in ceramic glazes, making them unsuitable for specific aesthetic applications. Buyers must therefore pay attention to the impurity levels specified by suppliers, as these can dramatically affect product performance.

Impact of Impurities:

Impurities can significantly alter the properties of zircon powder. For example:

- Iron Oxide (Fe2O3): Even low levels can lead to discoloration of the final product or affect its thermal stability.

- Titanium Dioxide (TiO2): This can modify the refractory properties and reduce the overall performance of the zircon in high-temperature settings.

- Aluminum Oxide (Al2O3): High levels may compromise the material’s structural integrity, leading to failures in demanding applications.

Holistic Approach to Quality Assessment:

Understanding the nuances of zircon powder’s properties informs procurement professionals, enabling them to choose materials that not only meet essential specifications but also enhance the performance and longevity of their end products. This knowledge goes beyond mere compliance; it forms the foundation of informed purchasing decisions, minimizing risks and maximizing value across the supply chain.

| Quality Aspect | Key Indicators | Impact on Performance |

|---|---|---|

| Particle Size Distribution | Mean particle size, D10, D50, D90 values | Packing density, sintering behavior, surface finish |

| Purity (ZrSiO4 content) | Percentage of ZrSiO4 | Refractoriness, chemical inertness, thermal stability |

| Impurities (e.g., Fe2O3, TiO2) | Specific impurity levels | Discoloration, altered thermal/mechanical properties |

| Density (True, Bulk, Tap) | g/cm³ values for each type | Material compaction, final product density, handling |

Identifying Reputable Suppliers Globally

Identifying reputable suppliers is paramount for international buyers sourcing high-quality zircon powder. A strong supplier relationship lays the foundation for a reliable supply chain.

Evaluating Suppliers:

● Reputation & Track Record: Scrutinize the supplier’s history within the industry. Look for established relationships with other international clients. Consistent quality and reliable delivery are hallmarks of a trustworthy supplier, so review their history of meeting customer expectations and deadlines.

● Certifications: Third-party certifications, particularly ISO 9001, are strong indicators of a supplier’s commitment to maintaining high-quality standards. These certifications demonstrate a systematic approach to quality management, giving buyers confidence in the supplier’s operational integrity.

● Production Capacity: Assess the supplier’s ability to meet your volume requirements consistently. A supplier with adequate production capabilities can adapt to fluctuations in demand, ensuring a steady flow of material. Inquire about their manufacturing processes and any recent investments in technology or equipment.

● Transparency: Openness regarding manufacturing processes and raw material sourcing helps build trust. Suppliers should be willing to provide detailed information about how they produce and handle zircon powder, including data on their quality control measures.

● Client Testimonials: Seek specific examples of past performance from existing clients, particularly in similar industries. Testimonials and case studies can reveal how the supplier has tackled challenges or fulfilled unique customer needs, providing a clearer picture of their reliability.

Red Flags:

- Unusually Low Prices: If a price seems too good to be true, it often is. Low-cost suppliers may be cutting corners on quality, leading to long-term issues.

- Lack of Transparency: If a supplier is hesitant to share detailed information about their processes or technical specifications, it could indicate deeper problems.

- Inability to Provide Specifications or Test Reports: A reputable supplier should readily provide documentation that confirms the quality and specifications of their zircon powder.

By carefully evaluating these aspects, buyers can align themselves with reputable suppliers who meet their quality expectations and foster long-term partnerships.

Key Technical Specifications for Sourcing

When sourcing zircon powder, international buyers must consider specific technical specifications that directly influence product performance and suitability for various applications.

Essential Specifications:

● Particle Size Distribution (PSD): Understanding PSD is crucial, as it encompasses not only the average particle size but also the range and distribution of different sizes. A narrow PSD typically indicates more consistent material behavior, which is vital for applications such as precision casting and advanced ceramics, where uniform packing density and sintering behavior are required. Laser diffraction is commonly used to obtain this data, providing metrics like D10, D50, and D90 values.

● Specific Gravity: This measurement indicates the inherent density of the zircon powder relative to water. A higher specific gravity often results in better packing efficiency and strength in the final product. It is particularly significant in applications where weight and durability are critical.

● Bulk Density: Bulk density measures the mass of the powder per unit volume, including the spaces between particles. This metric is not just important for basic calculations but also affects logistics and storage, as it dictates how much material can be transported or stored in specific containers. It thus plays a key role in cost management.

● Chemical Purity: Buyers should specify both the minimum ZrSiO4 content and the maximum allowable levels of impurities such as TiO2, Fe2O3, and Al2O3. Even minimal amounts of these impurities can have dramatic impacts, such as discoloration in ceramics or altered thermal stability in refractory applications.

● Moisture Content: This often-overlooked specification can significantly affect the flowability and consistency of zircon powder. High moisture levels can lead to agglomeration, impacting the ease of handling and processing.

● Material Safety Data Sheet (MSDS): This document is essential in providing information on handling, storage, and safety precautions necessary for regulatory compliance, especially important during international shipping.

Overall, understanding these specifications is critical for making informed purchasing decisions that align with your production needs and ensuring that the zircon powder will perform optimally in its intended application.

Key Technical Specifications Table:

| Specification | Description | Importance for Buyers |

|---|---|---|

| Particle Size Distribution (PSD) | Range and distribution of particle sizes (D10, D50, D90) | Affects packing, sintering, surface finish, and flowability |

| Specific Gravity | Ratio of powder density to water density | Indicates inherent material density, impacts final product density |

| Bulk Density | Mass per unit volume, including voids | Critical for transportation, storage, and handling efficiency |

| Chemical Purity (ZrSiO4) | Percentage of zirconium silicate | Directly impacts performance, refractoriness, and stability |

| Impurities (TiO2, Fe2O3, Al2O3) | Maximum allowable levels of contaminants | Affects color, thermal stability, and mechanical properties |

| Moisture Content (LOI) | Percentage of water content | Influences flowability, processing, and product quality |

| Material Safety Data Sheet (MSDS) | Safety, handling, and storage information | Essential for regulatory compliance and workplace safety |

Quality Control and Testing Procedures

Robust quality control is non-negotiable for buyers of zircon powder. Establishing a solid framework for testing and ensuring the quality of materials is essential to avoid costly production issues later.

Testing Procedures:

- Pre-shipment Inspections: Conduct visual checks, random sampling, and initial testing to identify potential issues at the supplier’s facility. Early detection helps prevent costly delays and rejections upon arrival.

- Third-party Testing: Utilize independent laboratories to perform a comprehensive range of tests on zircon powder. This verification adds an unbiased assessment of the material, ensuring it meets all specified requirements.

- Acceptance Criteria: Establish clear parameters for acceptable quality before purchasing. Define permissible ranges for key specifications, including ZrSiO4 content, impurity levels, and particle size distribution.

- Non-conformance Handling: Implement predefined procedures for managing materials that do not meet specifications. This process should include rejection criteria, return processes, and possible price adjustments. Having clear communication channels with suppliers will facilitate efficient resolutions.

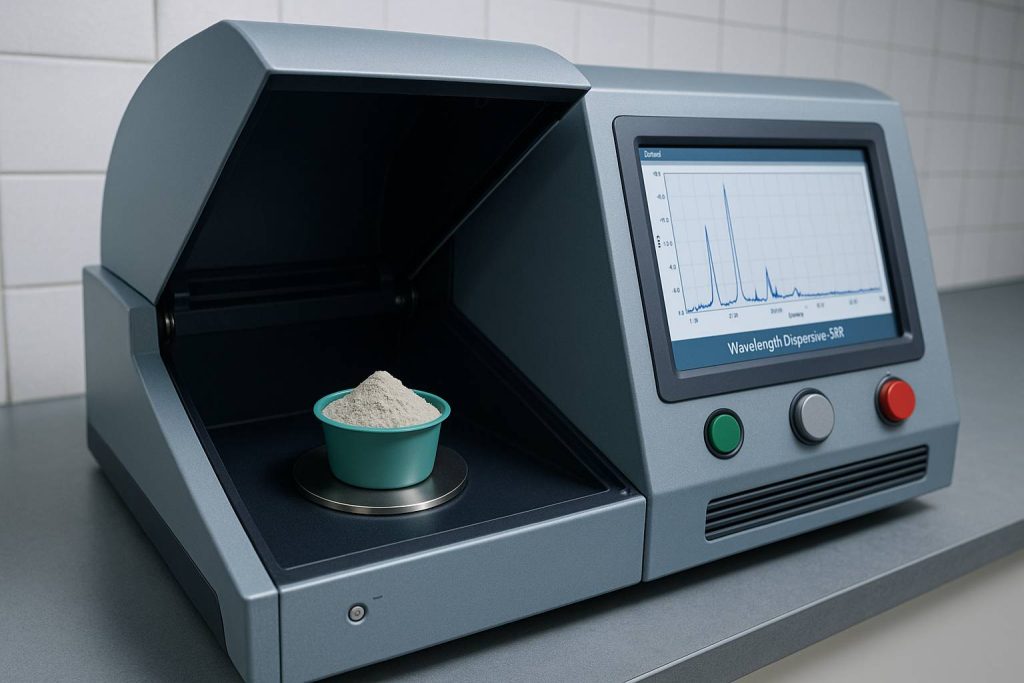

Common Testing Methods:

| Test Method | Principle | What it Measures | Relevance for Zircon Powder |

|---|---|---|---|

| X-ray Fluorescence (XRF) | Emits X-rays, measures secondary X-rays | Elemental composition (e.g., Zr, Si, Fe, Ti) | Verifies chemical purity and impurity levels |

| X-ray Diffraction (XRD) | X-ray beam interacts with crystalline material | Crystalline structure, phase identification | Confirms mineral phase (zircon) and detects other crystalline phases |

| Laser Diffraction | Laser beam scatters off particles | Particle size distribution (D10, D50, D90) | Essential for understanding material behavior in applications |

| Gas Pycnometry | Measures volume displacement by gas | True density of solid particles | Determines intrinsic material density |

| Sieve Analysis | Passes powder through sieves of decreasing mesh size | Coarse particle size distribution | Basic method for larger particle fractions |

Each of these methods plays a crucial role in ensuring that the zircon powder meets high-quality standards and fulfills performance expectations for diverse applications.

Logistics, Packaging, and Shipping Considerations

For international buyers, the logistics of zircon powder sourcing extend beyond mere transportation. Effective management of packaging, storage, and shipping is vital to maintaining the quality of zircon powder throughout its journey.

Key Considerations:

- Packaging Options: Choosing the right packaging is essential to protect the powder from contamination and moisture. Options include:

- Multi-ply paper bags: Suitable for smaller quantities and standard transport.

- Woven polypropylene bags: Offer more durability and resistance to moisture.

- Jumbo bags: Economical for bulk shipments, reducing handling costs and streamlining logistics.

- Storage Requirements: Proper storage conditions are critical for preserving the integrity of zircon powder before and after shipment. It should be stored in:

- A dry and cool environment to prevent moisture absorption.

- Areas that shield the material from direct sunlight and potential contamination from other substances.

- Shipping Regulations: Navigating international shipping laws can be complex. Buyers need to be aware of:

- Customs requirements: Each country has specific regulations for importing mineral products.

- Import duties and tariffs: Understanding these costs helps in budgeting effectively.

- Incoterms: These globally recognized trade terms define the responsibilities and risks involved, thus influencing the final landed cost of zircon powder.

Financial Implications:

- Understanding Incoterms such as FOB (Free On Board), CIF (Cost, Insurance and Freight), or DDP (Delivered Duty Paid) is vital for accurate cost calculations and risk allocation.

- Effective customs clearance is key to avoiding delays and minimizing additional charges. Ensuring that all documentation, such as commercial invoices, packing lists, and Material Safety Data Sheets (MSDS), is accurate and complete can expedite this process.

Table: Key Considerations in Logistics and Packaging

| Aspect | Key Considerations | Impact on Sourcing |

|---|---|---|

| Packaging | Type (bags, jumbo bags), sealing, moisture barriers | Quality preservation, handling efficiency, cost |

| Storage | Dry, cool environment, contamination prevention | Prevents degradation, ensures material integrity |

| Shipping Regulations | Customs, duties, declarations, Incoterms | Compliance, cost calculation, risk allocation |

| Freight Forwarders | Experience with chemical/mineral shipments | Streamlines process, avoids delays |

| Documentation | Commercial invoices, certificates of analysis (COA), MSDS | Customs clearance, regulatory compliance |

By addressing these logistics, packaging, and shipping considerations effectively, buyers can help ensure a seamless procurement process and maintain the quality of zircon powder from supplier to facility.

Risk Management in Zircon Powder Procurement

Procuring zircon powder, especially from international sources, involves inherent risks that require proactive management to ensure a stable supply chain.

Common Risks:

- Supply Chain Disruptions: These can arise from geopolitical instability, natural disasters, and transportation issues that may cause delays or complete interruptions in supply. To mitigate this, diversifying your supplier base is essential. By establishing relationships with multiple qualified suppliers across different regions, you can create a buffer against unexpected events and reduce the impact of potential disruptions.

- Quality Inconsistencies: Even with thorough vetting processes, there is always a risk that a batch of material may not meet the agreed-upon specifications. Implementing robust incoming inspection protocols is crucial to detect inconsistencies before they affect production. Clear non-conformance procedures should also be established, detailing the actions to be taken when material does not meet quality standards.

- Financial Risks: Fluctuations in currency exchange rates, unexpected tariffs, or changes in commodity prices can significantly impact the landed cost of zircon powder. Businesses can employ hedging strategies, such as forward contracts, or negotiate long-term supply agreements with fixed pricing to manage these financial uncertainties effectively.

- Legal and Regulatory Compliance Risks: Varying international trade laws, environmental regulations, and specific product safety standards can pose significant challenges. Staying informed about the evolving landscape of regulations and ensuring that your suppliers are compliant can prevent legal complications and ensure seamless market access.

Mitigation Strategies:

| Risk Category | Examples | Mitigation Strategies |

|---|---|---|

| Supply Chain | Geopolitical events, natural disasters | Supplier diversification, buffer stock |

| Quality | Impurities, inconsistent PSD | Robust inspection, third-party testing |

| Financial | Currency fluctuations, tariffs | Hedging, fixed-price contracts |

| Legal/Regulatory | Trade laws, environmental rules | Due diligence, legal counsel |

| Reputational | Product failure, non-compliance | Quality assurance, transparent communication |

By systematically identifying, assessing, and mitigating these risks, international buyers can secure a more reliable supply of high-quality zircon powder, ensuring both operational stability and profitability.

Conclusion

Sourcing quality zircon powder internationally is a complex but manageable endeavor. This guide has outlined key steps for B2B buyers. We covered understanding material specifications, vetting global suppliers, navigating technical details, implementing quality control, and managing logistics. We also addressed crucial risk management strategies. By applying these principles, businesses can secure a consistent supply of high-grade zircon powder. This ensures product integrity and operational efficiency. Global Industry offers specialized expertise in material procurement and quality verification. We help companies streamline their sourcing processes. Our team provides tailored solutions to meet your specific material needs. Partner with us to enhance your supply chain resilience. Contact us today to discuss how our solutions can benefit your business.

FAQ Section

Q1: What is the most important factor when sourcing zircon powder internationally?

The most important factor is ensuring consistent quality that meets your specific application requirements. This involves thorough technical specification, rigorous testing, and reliable supplier vetting.

Q2: How can I verify a supplier’s credibility?

Verify a supplier’s credibility by checking their industry reputation, seeking client references, reviewing certifications (like ISO 9001), assessing their production capacity, and demanding transparency in their processes and material sourcing.

Q3: Why are Incoterms important in international zircon powder procurement?

Incoterms define the responsibilities of buyers and sellers for delivery, costs, and risks in international trade. Understanding them is crucial for accurate cost calculation, risk allocation, and smooth logistics, directly impacting the final landed cost of the powder.

Q4: What are common impurities in zircon powder and their effects?

Common impurities include iron oxide (Fe2O3), titanium dioxide (TiO2), and aluminum oxide (Al2O3). These can cause discoloration, alter thermal stability, or affect mechanical properties, especially in high-temperature applications.

Q5: How can I mitigate supply chain risks when sourcing zircon powder?

Mitigate supply chain risks by diversifying your supplier base across different regions, establishing clear contracts with force majeure clauses, and maintaining strong, transparent relationships with all your suppliers.