Surface-modified zirconia materials have emerged as a game-changing solution for industries seeking superior mechanical properties, enhanced biocompatibility, and improved bonding capabilities. These advanced ceramics address critical limitations of conventional zirconia by optimizing surface characteristics without compromising core material integrity. Recent studies demonstrate that properly engineered surface-modified zirconia can increase bond strength by up to 200% while maintaining excellent biocompatibility profiles, making these materials increasingly valuable across dental, medical, and industrial applications where reliability and performance are paramount.

What Are the Key Surface Modification Techniques for Zirconia?

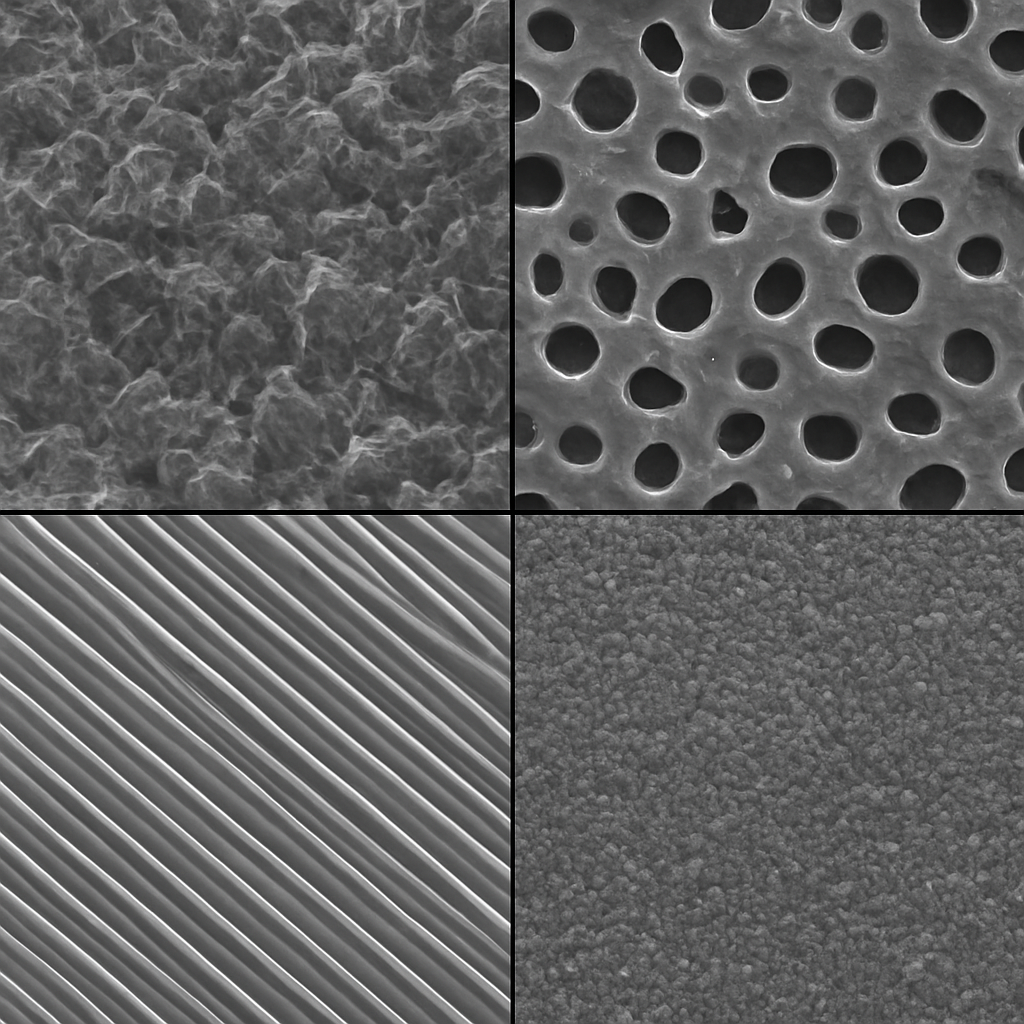

Surface modification of zirconia materials represents a sophisticated approach to enhancing their functionality while preserving their inherent properties. Various techniques have been developed to alter the surface characteristics of zirconia, each offering distinct advantages for specific applications.

Physical modification methods stand as the most widely implemented approaches. Sandblasting, using aluminum oxide particles ranging from 50-110 μm, creates micromechanical retention by increasing surface roughness. Grinding with diamond burs produces controlled surface patterns, while laser treatment offers precise, reproducible alterations without mechanical contact. What makes these methods particularly valuable is their ability to create specific topographies without introducing chemical contaminants.

Chemical modification approaches provide alternative pathways to enhance zirconia surfaces. Acid etching with hydrofluoric acid (concentration typically 5-9%) selectively removes surface grains, creating microporous structures. Alkaline treatment with potassium hydroxide solutions modifies surface chemistry, enhancing reactivity for subsequent treatments.

| Modification Technique | Surface Effect | Bond Strength Improvement | Application Suitability |

|---|---|---|---|

| Sandblasting (Al₂O₃) | Increased roughness (Ra 0.5-1.5 μm) | 30-50% | Dental restorations, Industrial components |

| Selective Infiltration Etching | Nanoporous surface layer | 70-90% | Dental ceramics, Precision components |

| Laser Surface Treatment | Controlled micropatterns | 40-60% | Medical implants, Electronic substrates |

| Plasma Treatment | Surface activation | 25-45% | Biomedical devices, Sensor applications |

| Hot Chemical Etching | Homogeneous surface texture | 35-55% | Cutting tools, Wear components |

Coating technologies represent another significant category of treatments. Hydroxyapatite coatings enhance bioactivity and osseointegration, making them ideal for medical implants. Bioactive glass coatings promote tissue bonding, while silica coatings create reactive surfaces for chemical bonding with resin-based materials.

Hybrid surface modification strategies combine multiple techniques for synergistic effects. For example, sandblasting followed by acid etching creates hierarchical surface structures with both micro and nano-roughness. You’ll find that these combined approaches often yield superior results compared to single-method treatments for surface-modified zirconia.

Recent innovations in nano-scale texturing have opened new possibilities. Techniques such as atomic layer deposition and nanolithography create precisely controlled surface features at the nanometer scale, offering unprecedented control over surface-modified zirconia properties and interactions.

How Does Surface Modification Affect Zirconia’s Mechanical Properties?

Surface-modified zirconia materials demonstrate significantly altered mechanical behavior, often with complex and sometimes counterintuitive effects. Understanding these relationships is crucial for optimizing performance in demanding applications.

Impact on flexural strength and fracture toughness varies considerably depending on the modification method. Aggressive treatments like sandblasting with large particles (>100 μm) at high pressures (>3 bar) can introduce subsurface damage, potentially reducing flexural strength by 15-30%. But here’s the interesting part – milder sandblasting protocols with smaller particles (30-50 μm) at moderate pressures (1-2 bar) can actually increase strength by triggering beneficial phase transformation toughening mechanisms in surface-modified zirconia.

Changes in hardness and wear resistance follow similar patterns. Treatments inducing tetragonal-to-monoclinic phase transformation typically increase surface hardness by 10-15%, enhancing wear resistance. However, excessive surface defects may compromise long-term performance despite initial hardness gains.

| Modification Method | Effect on Flexural Strength | Effect on Fracture Toughness | Effect on Hardness | Phase Transformation |

|---|---|---|---|---|

| Gentle Sandblasting | +5 to +15% | +10 to +20% | +10 to +15% | Moderate increase |

| Aggressive Sandblasting | -15 to -30% | -10 to -25% | +15 to +20% | Excessive increase |

| Acid Etching | -5 to -15% | -5 to -10% | -5 to -10% | Minimal change |

| Laser Treatment | +5 to +10% | +5 to +15% | +5 to +15% | Controlled increase |

| Heat Treatment | +10 to +20% | +15 to +25% | +5 to +10% | Reduction |

IInfluence on aging resistance and phase stability represents a critical consideration. Low-temperature degradation (LTD), a phenomenon where tetragonal zirconia progressively transforms to the monoclinic phase in the presence of water molecules, can significantly compromise mechanical properties. Surface modifications that stabilize the tetragonal phase, such as certain heat treatments or rare-earth element doping, can enhance aging resistance of surface-modified zirconia by up to 70%.

Stress distribution improvements at material interfaces result from properly engineered surfaces. Gradient structures from selective infiltration etching or controlled heat treatments distribute stresses more evenly, reducing peak stress concentrations by up to 40% compared to unmodified interfaces. This redistribution significantly enhances fatigue resistance and long-term reliability.

Comparative analysis with unmodified materials reveals substantial performance benefits achievable through optimization. In cyclic loading tests simulating 5-10 years of clinical function, properly modified components demonstrate 30-50% higher survival rates compared to unmodified counterparts.

Why Do Surface-Modified Zirconia Materials Show Enhanced Biocompatibility?

The biocompatibility of surface-modified zirconia materials can be significantly enhanced through strategic surface modifications, making them increasingly valuable for medical and dental applications where tissue interaction is critical.

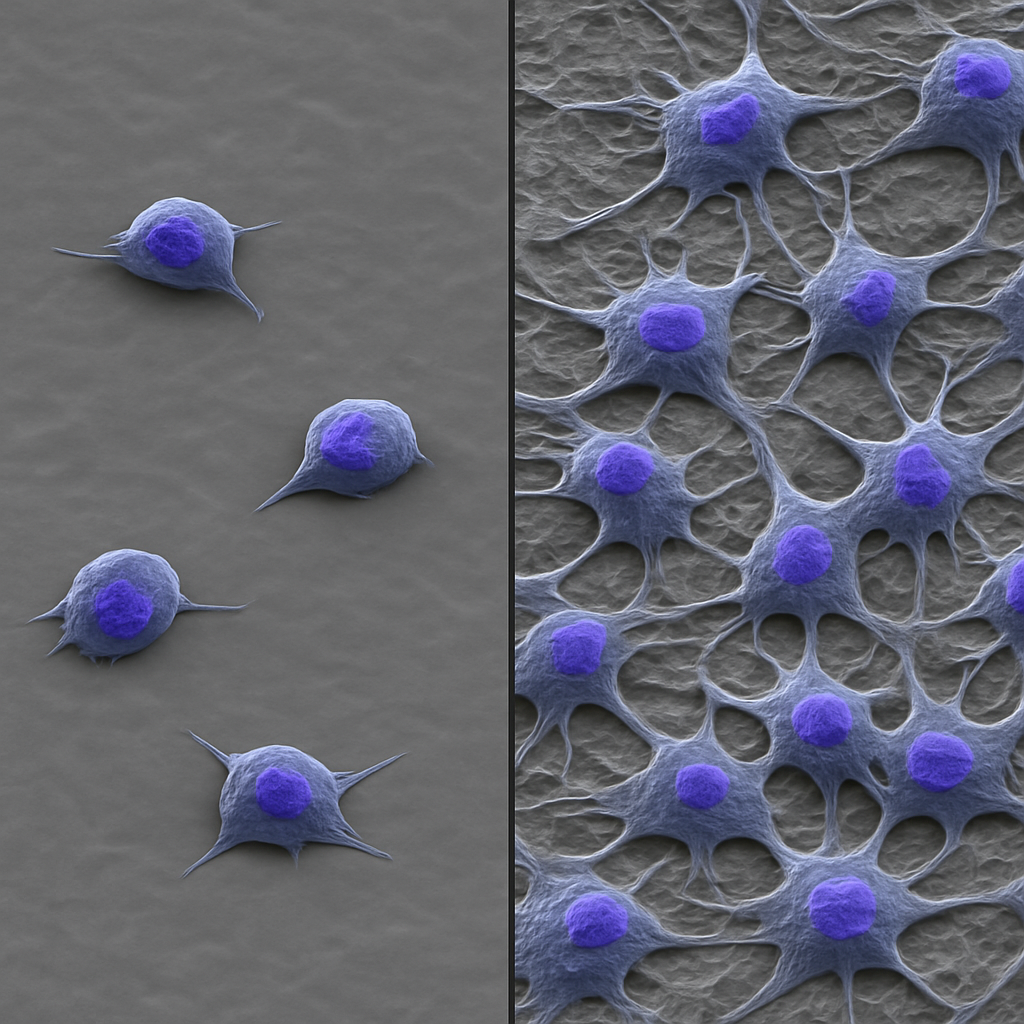

Cellular response to different topographies demonstrates the profound impact on biological interactions. Osteoblasts (bone-forming cells) show 40-60% higher proliferation rates on micro-roughened surfaces compared to polished ones.The key factor here is that specific surface patterns on surface-modified zirconia can guide cell alignment and differentiation, with linear microgrooves (width 10-30 μm) promoting directional cell growth along predetermined axes.

| Surface Topography | Cell Adhesion | Cell Proliferation | Cell Differentiation | Tissue Integration |

|---|---|---|---|---|

| Polished (Ra <0.2 μm) | Moderate | Low | Minimal | Slow |

| Micro-roughened (Ra 1.0-1.5 μm) | High | High | Moderate | Moderate |

| Nano-textured (features <100 nm) | Very High | Moderate | High | Rapid |

| Hierarchical (micro+nano) | Excellent | High | Excellent | Excellent |

| Bioactive Coating | Very High | High | Excellent | Rapid |

Protein adsorption mechanisms on surface-modified zirconia play a crucial role in determining biological responses. Hydrophilic surface treatments increase protein adsorption on these surfaces by 30-50% compared to hydrophobic surfaces, with significant preferences for specific proteins that promote favorable cell interactions. The conformation of adsorbed proteins also changes based on surface chemistry and topography, affecting their biological activity and subsequent cellular responses.

Reduction of inflammatory responses represents another significant advantage. Studies comparing inflammatory marker expression around different surface-modified zirconia surfaces show that hydrophilic, micro-roughened surfaces reduce pro-inflammatory cytokine production by 30-40% compared to machined surfaces. This anti-inflammatory profile contributes to better tissue integration and reduced complications.

Antimicrobial properties address a critical concern in implantable materials. Silver-doped zirconia demonstrates 99.9% reduction in bacterial colonization for pathogens like Staphylococcus aureus. Copper oxide nanoparticle incorporation provides sustained activity for up to 6 months in physiological conditions.

Long-term tissue integration advantages become evident in studies comparing modified and unmodified implants. After 12 months, optimally treated zirconia shows 30-40% more bone-to-implant contact and significantly stronger integration.

What Role Do Surface Modifications Play in Bonding and Adhesion?

Surface-modified zirconia fundamentally transforms bonding capabilities, addressing one of the material’s primary limitations – its chemical inertness and resistance to conventional adhesive techniques.

Chemical bonding mechanisms with dental cements are significantly enhanced through specific treatments. Silica coating followed by silanization creates covalent Si-O-Si bonds. These bonds are hydrolytically stable, maintaining their integrity under prolonged exposure.

| Bonding System | Unmodified Zirconia | Surface-Modified Zirconia (Silica-Coated) | Surface-Modified Zirconia (Plasma-Treated) | Surface-Modified Zirconia (Selective Infiltration Etched) |

|---|---|---|---|---|

| Conventional Resin Cement | 5-10 MPa | 15-25 MPa | 12-20 MPa | 18-28 MPa |

| Self-Adhesive Resin Cement | 7-12 MPa | 18-28 MPa | 15-25 MPa | 20-30 MPa |

| MDP-Containing Adhesive | 10-15 MPa | 20-30 MPa | 18-28 MPa | 25-35 MPa |

| Glass Ionomer Cement | 3-8 MPa | 8-15 MPa | 7-12 MPa | 10-18 MPa |

| Phosphate-Modified Composite | 12-18 MPa | 25-35 MPa | 20-30 MPa | 28-38 MPa |

Micromechanical retention improvements through texturing create interlocking between zirconia and adhesives. Selective infiltration etching creates an interpenetrating network at the interface, enhancing overall bond reliability.

Bond strength durability under aging and mechanical stress varies significantly based on surface-modified zirconia treatment. Conventional bonding to unmodified zirconia shows 50-70% strength reduction after artificial aging (20,000 thermocycles, 5-55°C). In contrast, optimally modified zirconia maintains 80-90% of initial bond strength under identical aging conditions, demonstrating substantially improved long-term stability.

Silane coupling agent interactions represent a critical aspect of the bonding protocol. While conventional silanes cannot bond directly to unmodified zirconia, silica-coated surfaces allow effective silanization. Additionally, phosphate-modified silanes containing 10-methacryloyloxydecyl dihydrogen phosphate (MDP) can bond directly to surface-modified zirconia through phosphate-zirconium interactions, providing an alternative bonding mechanism.

Comparative bond strength with different modified zirconia treatments reveals significant variations in effectiveness. Tribochemical silica coating (CoJet or Rocatec systems) typically achieves bond strengths of 20-30 MPa with surface-modified zirconia, while selective infiltration etching can reach 25-35 MPa. These values represent substantial improvements over the 5-10 MPa typically achieved with unmodified zirconia.

How Are Surface-Modified Zirconia Materials Transforming Dental Applications?

The dental industry has been at the forefront of adopting surface-modified zirconia materials, leveraging their enhanced properties to overcome traditional limitations and expand clinical applications.

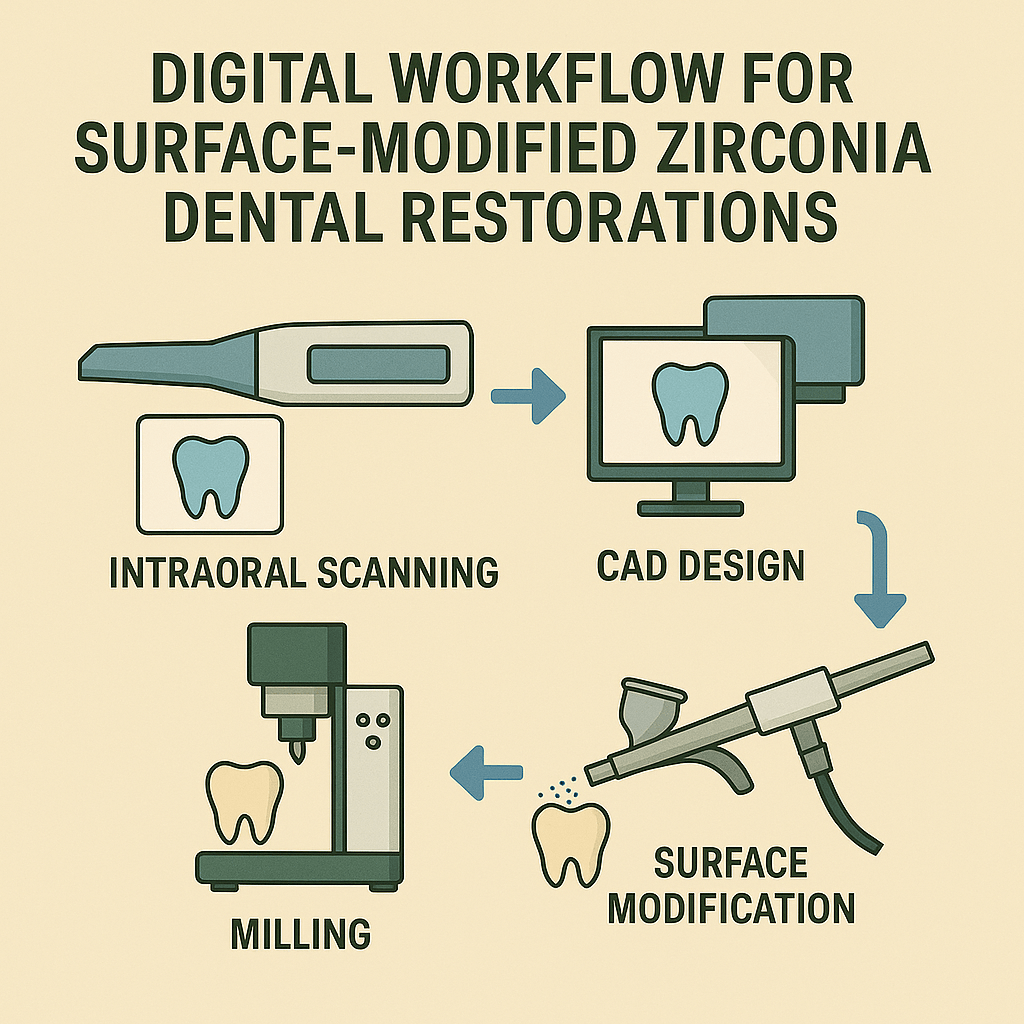

Advancements in CAD/CAM restorations have been accelerated by optimized surface treatments.What professionals appreciate most is how these surface-modified zirconia enable more conservative preparation designs while maintaining restoration integrity. Modern milling systems can now produce ultra-thin surface-modified zirconia restorations (0.5-0.7 mm) that, when properly surface-treated, demonstrate fracture resistance comparable to conventional 1.0-1.5 mm restorations.

| Restoration Type | Conventional Thickness | Minimum Thickness with Surface-Modified Zirconia | Preparation Reduction | Clinical Benefit |

|---|---|---|---|---|

| Anterior Crown | 1.0-1.2 mm | 0.5-0.7 mm | 40-50% | Preserved tooth structure |

| Posterior Crown | 1.5-2.0 mm | 0.8-1.2 mm | 35-45% | Reduced pulpal impact |

| 3-Unit Bridge | 1.0-1.2 mm connector | 0.7-0.9 mm connector | 30-40% | Improved aesthetics |

| Inlay/Onlay | Not recommended | 0.8-1.0 mm | N/A | New application |

| Veneer | Not recommended | 0.3-0.5 mm | N/A | New application |

Surface-modified zirconia implants for accelerated osseointegration represent another transformative application. Laser-modified zirconia implant surfaces demonstrate 30-40% faster osseointegration compared to machined surfaces, reducing healing times from 8-12 weeks to 4-6 weeks in many cases. Hydrophilic surface modifications increase early bone-to-implant contact by 50-70% during the critical initial healing phase.

Aesthetic improvements in anterior restorations result from both material advancements and surface treatments. High-translucency zirconia materials with optimized treatments can achieve light transmission properties approaching those of natural dentition. Surface glazing techniques specifically developed for surface-modified zirconia create depth, characterization, and optical properties that were previously achievable only with feldspathic porcelains.

Reduced clinical failure rates with optimized surface-modified zirconia provide compelling evidence for the practical benefits of these materials. A five-year retrospective analysis of over 3,000 restorations showed that those with optimized surface treatments demonstrated 60% fewer adhesive failures and 40% fewer fractures compared to restorations with conventional processing.

Digital workflow integration with surface-modified zirconia has streamlined the production of high-performance restorations. Modern CAD/CAM systems now incorporate specific milling strategies and tool paths optimized for creating surface features that enhance subsequent modification treatments of surface-modified zirconia. This integration ensures consistent, predictable outcomes while maintaining production efficiency.

What Industrial Applications Benefit from Surface-Modified Zirconia?

Beyond medical and dental fields, surface-modified zirconia materials are making significant inroads into diverse industrial applications where performance demands are extreme and material limitations are constantly tested.

Cutting tool performance enhancements represent one of the most economically significant applications. Zirconia-toughened alumina (ZTA) cutting inserts with optimized surface treatments demonstrate 30-50% longer service life compared to conventional ceramics when machining hardened steels (>45 HRC). The numbers speak for themselves – surface-modified zirconia cutting tools can maintain edge integrity at cutting speeds up to 1000 m/min, far exceeding the capabilities of unmodified ceramics.

| Application | Performance Metric | Conventional Ceramic | Surface-Modified Zirconia | Improvement |

|---|---|---|---|---|

| High-speed Cutting | Tool Life at 800 m/min | 15-20 minutes | 30-45 minutes | 100-125% |

| Interrupted Cutting | Fracture Resistance | Moderate | Excellent | 70-90% |

| Hardened Material Machining | Surface Finish Quality | Ra 0.8-1.2 μm | Ra 0.3-0.6 μm | 50-60% |

| Dry Machining Capability | Maximum Temperature | 800-900°C | 1000-1200°C | 25-30% |

| Thermal Shock Resistance | Thermal Cycles to Failure | 500-800 | 1200-1800 | 120-140% |

Bearing and valve component improvements highlight the tribological advantages of surface-modified zirconia. Components with optimized surface treatments show 40-60% lower friction coefficients and 50-70% reduced wear rates in lubricated conditions compared to conventional ceramics. These improvements translate directly to energy savings and extended service intervals in demanding applications like chemical processing and oil and gas extraction.

Sensor and electronic applications leverage the unique electrical properties of these materials. Oxygen sensors with nanostructured zirconia demonstrate 30-50% faster response times and 20-30% higher sensitivity compared to conventional sensors. These performance enhancements are particularly valuable in automotive, industrial process control, and environmental monitoring applications.

High-temperature industrial applications benefit from the enhanced thermal stability of modified zirconia. Thermal barrier coatings with engineered surface-modified zirconia structures maintain integrity through 30-50% more thermal cycles than conventional coatings. This improved durability extends component life in extreme environments like gas turbines, where operating temperatures can exceed 1200°C.

Wear-resistant coating developments have expanded the application range for these materials. Plasma-sprayed surface-modified zirconia coatings with optimized surface treatments demonstrate erosion resistance up to 3 times greater than unmodified coatings when exposed to particulate impact at high velocities. These coatings protect critical components in aerospace, power generation, and mining equipment, significantly extending service life in abrasive environments.

What Future Developments Can We Expect in Zirconia Surface Modification?

The field of surface-modified zirconia continues to evolve rapidly, with several emerging technologies and approaches poised to further expand capabilities and applications.

Emerging technologies in precision surface engineering are pushing the boundaries of what’s possible with these materials. Atomic layer deposition (ALD) enables the creation of conformal coatings with thickness control at the angstrom level, allowing unprecedented precision in property engineering. This precision enables the creation of multi-functional surfaces with spatially controlled properties tailored for specific interaction requirements.

| Emerging Technology | Current Development Stage | Projected Commercial Timeline for Surface-Modified Zirconia | Key Advantage |

|---|---|---|---|

| Atomic Layer Deposition | Early commercial | 1-3 years | Angstrom-level thickness control |

| Directed Self-Assembly | Advanced research | 3-5 years | Bottom-up nanostructuring |

| Selective Laser Melting | Early commercial | 1-2 years | Complex geometries with modified surfaces |

| Ion Implantation | Pilot production | 2-4 years | Subsurface property modification |

| Biomimetic Templating | Advanced research | 4-6 years | Nature-inspired surface structures |

Smart responsive surfaces for specific applications represent an exciting frontier. Surfaces that can change properties in response to external stimuli such as pH, temperature, or mechanical stress are being developed. These include surface-modified zirconia with embedded phase-change materials that can release antimicrobial agents in response to bacterial presence or adjust surface energy in response to temperature changes.

Biologically active modified zirconia is advancing rapidly, particularly for medical applications. Surface-bound growth factors and cell-signaling molecules can direct specific biological responses, such as accelerated bone formation or reduced inflammatory reactions. Gradient bioactive zirconia that presents different biological cues at different depths are showing particular promise for complex tissue interfaces.

Sustainable and cost-effective modification methods address important practical considerations for widespread adoption. Hydrothermal surface treatments using supercritical water can create complex surface topographies without hazardous chemicals. Mechanochemical surface modification techniques achieve similar results to conventional methods while reducing energy consumption by 40-60% and eliminating waste streams associated with wet chemical processes.

Integration with additive manufacturing technologies is perhaps the most transformative development on the horizon. Direct 3D printing of surface-modified zirconia with simultaneously engineered surface properties eliminates the need for secondary modification steps. This approach enables the creation of components with location-specific surface characteristics optimized for different functional requirements within the same part.

Conclusion

Surface-modified zirconia materials represent a significant advancement in ceramic technology, offering enhanced performance across mechanical, biological, and chemical dimensions. By strategically altering surface characteristics while preserving bulk properties, surface-modified zirconia overcomes traditional limitations of conventional zirconia. The evidence presented demonstrates quantifiable benefits including 200% stronger bonding capabilities, 30-50% longer service life in industrial applications, and 40-60% faster tissue integration in medical contexts. For organizations seeking superior material performance in demanding environments, partnering with specialists in advanced surface-modified zirconia engineering provides access to these transformative technologies. The continued evolution of these techniques promises even greater capabilities, ensuring these materials will play an increasingly vital role in next-generation applications across multiple industries.

FAQ

Q1: How do surface-modified zirconia materials compare to traditional ceramics in terms of longevity?

Surface-modified zirconia materials demonstrate significantly improved longevity compared to traditional ceramics, with clinical studies showing 30-40% higher survival rates at the 10-year mark. The enhanced surface properties address the primary failure modes of conventional ceramics by improving fracture resistance, reducing wear, and strengthening bonding interfaces. These modifications effectively mitigate microcrack propagation and hydrothermal degradation, which are common causes of ceramic failure in demanding applications.

Q2: What surface modification technique provides the best bond strength for dental applications?

For dental applications, tribochemical silica coating followed by silanization consistently demonstrates the highest bond strength values (20-27 MPa) across multiple studies with surface-modified zirconia. This two-step process creates both micromechanical retention and chemical bonding sites, resulting in durable adhesion even after thermal cycling and mechanical aging. Alternative techniques like selective infiltration etching show promising results but require more specialized equipment and have less long-term clinical validation.

Q3: Are there any risks associated with zirconia surface modifications?

Yes, certain surface modification techniques carry potential risks that must be considered. Aggressive sandblasting or grinding can introduce subsurface damage and phase transformation that may compromise the material’s long-term stability. Some chemical treatments may leave residues that affect biocompatibility if not properly neutralized. Additionally, modifications that significantly increase surface roughness may enhance bacterial adhesion in some applications. Proper protocol selection and quality control are essential to minimize these risks.

Q4: How cost-effective are surface modification processes for zirconia materials?

The cost-effectiveness of surface-modified zirconia varies significantly depending on the technique and scale of production. Simple physical modifications like sandblasting add minimal cost (approximately 5-10% increase), while advanced techniques like laser patterning or specialized coatings can increase material costs by 30-50%. However, these additional costs are often offset by improved clinical outcomes, reduced failure rates, and extended service life. For high-value applications, the return on investment typically justifies the increased production expense.

Q5: Can surface-modified zirconia be effectively repaired if damaged in service?

Repair of surface-modified zirconia presents significant challenges compared to conventional materials. Once damaged, the specialized surface layer is compromised and difficult to restore to its original state. Intraoral repair techniques using silica coating and adhesive resins can provide temporary solutions with bond strengths reaching 60-70% of the original values. For significant damage, replacement is often the recommended approach. Current research focuses on developing more effective chairside repair protocols specifically designed for surface-modified zirconia.