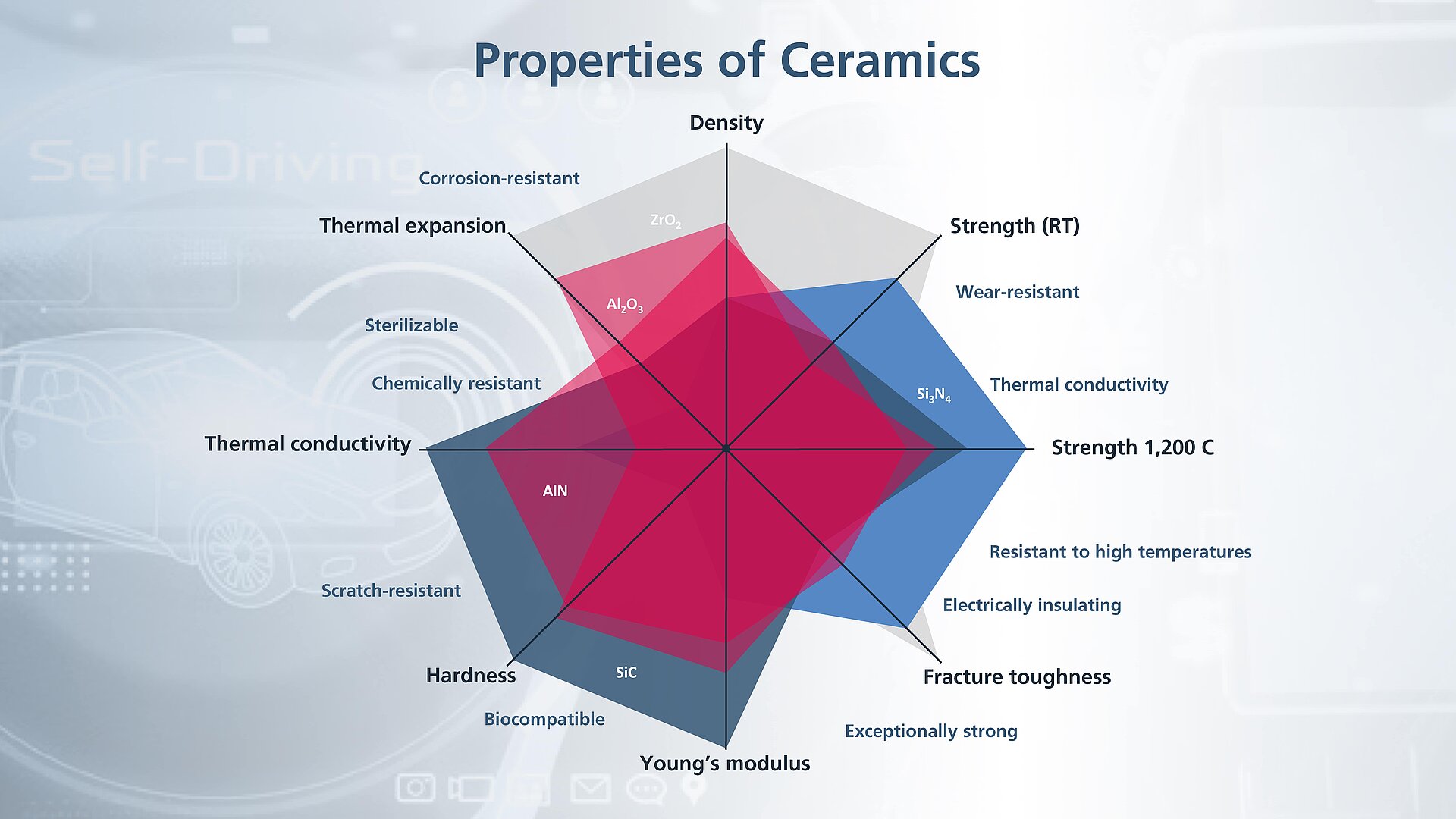

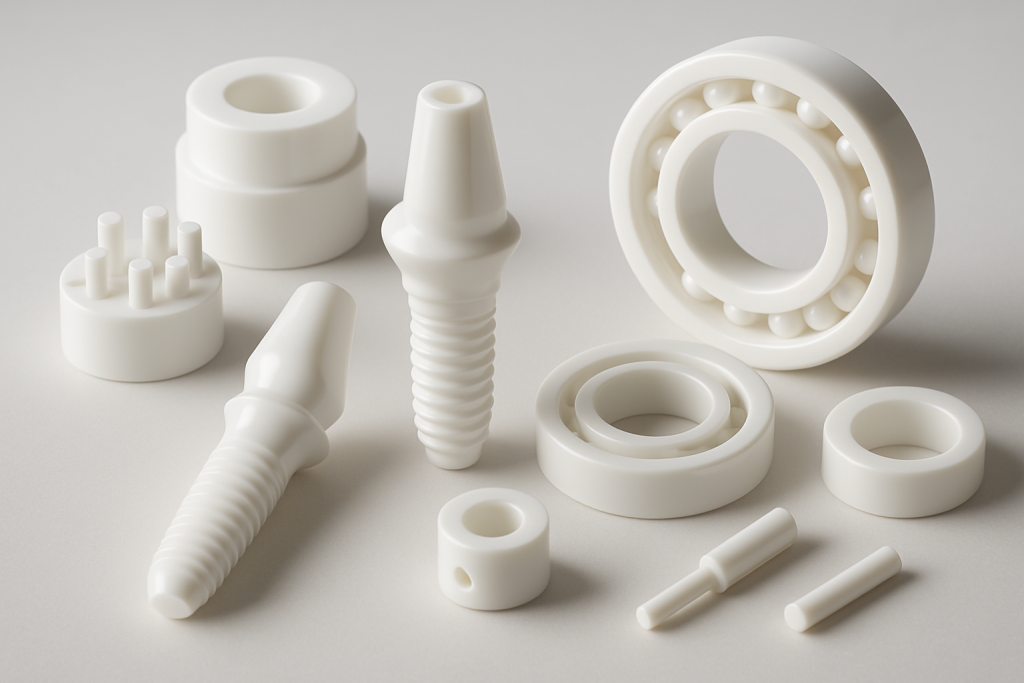

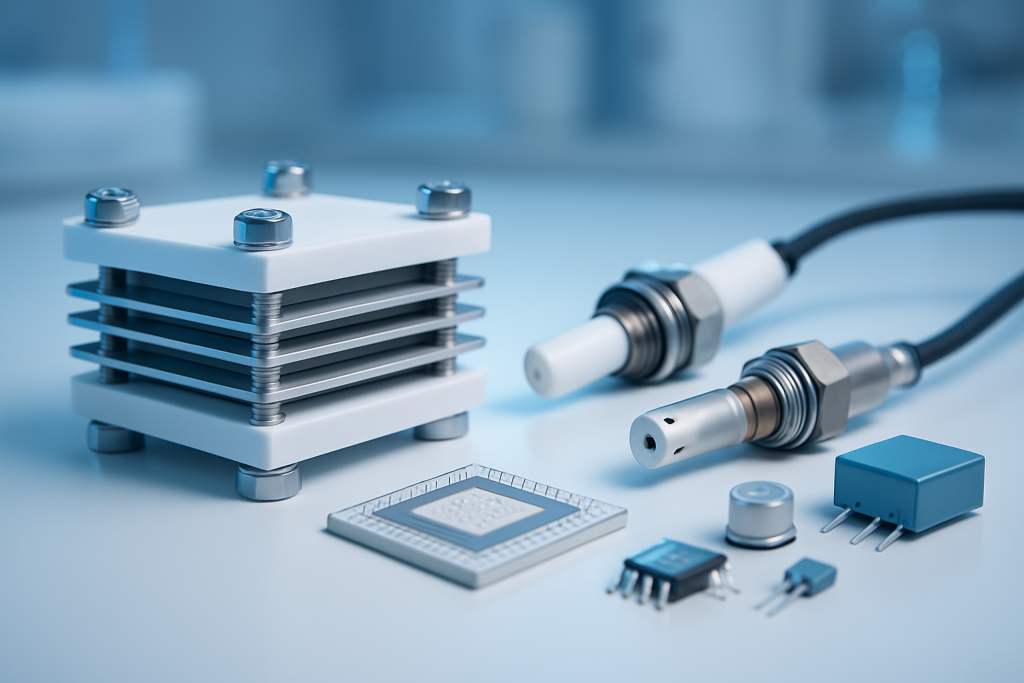

Zirconia, or zirconium dioxide (ZrO₂), is an advanced ceramic material renowned for its exceptional combination of mechanical, thermal, and electrical properties.

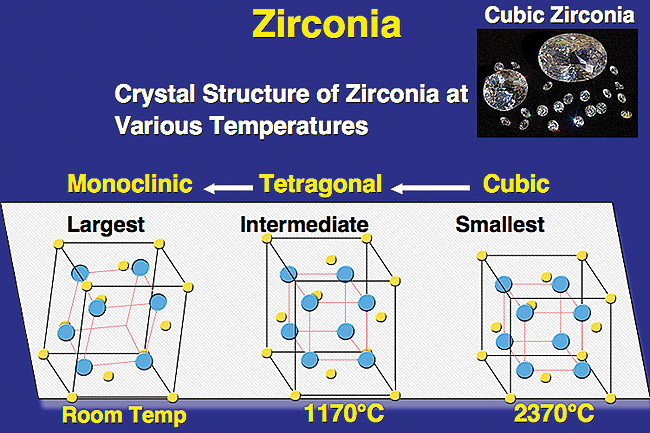

Zirconia Powder (ZrO₂) is a high-performance ceramic material renowned for its extremely high melting point (~2715°C), exceptional wear resistance, corrosion resistance, and chemical stability. It exists in three crystalline phases—monoclinic, tetragonal, and cubic—with Yttria-Stabilized Zirconia (YSZ) being widely utilized for its superior thermal stability and mechanical strength.

Key Properties:

| Product | Zr(Hf)O₂ | Y₂O₃ | SiO₂ | Na₂O | CL- | ig.loss | Bulk density | BET | D90 |

|---|---|---|---|---|---|---|---|---|---|

| Code | (min)% | % | (max)% | (max)% | (max)% | (max)% | g/m²(max)% | m²g/ | <1.0 |

| JA-TAP-OY | 99.9 | 0 | 0.002 | 0.005 | 0.01 | 1 | – | 5-15 | <1.0 |

| JA-TAP-3Y | 94.5 | 5.30+0.20 | 0.002 | 0.005 | 0.03 | 3 | 1.15-1.45 | 6-32 | <1.0 |

| JA-TAP-5Y | 89.5 | 8.75+0.25 | 0.005 | 0.005 | 0.01 | 1 | – | 6-10 | <1.0 |

| ZTA | 19 | 1.5±0.20 | 0.005 | 0.005 | 0.5 | 3 | – | 6-10 | <5.0 |

Specific surface area, median particle size, bulk density and shrinkage can be controlled according to customer requirements. Granulation powder and air flow powder can be produced according to customer requirements.

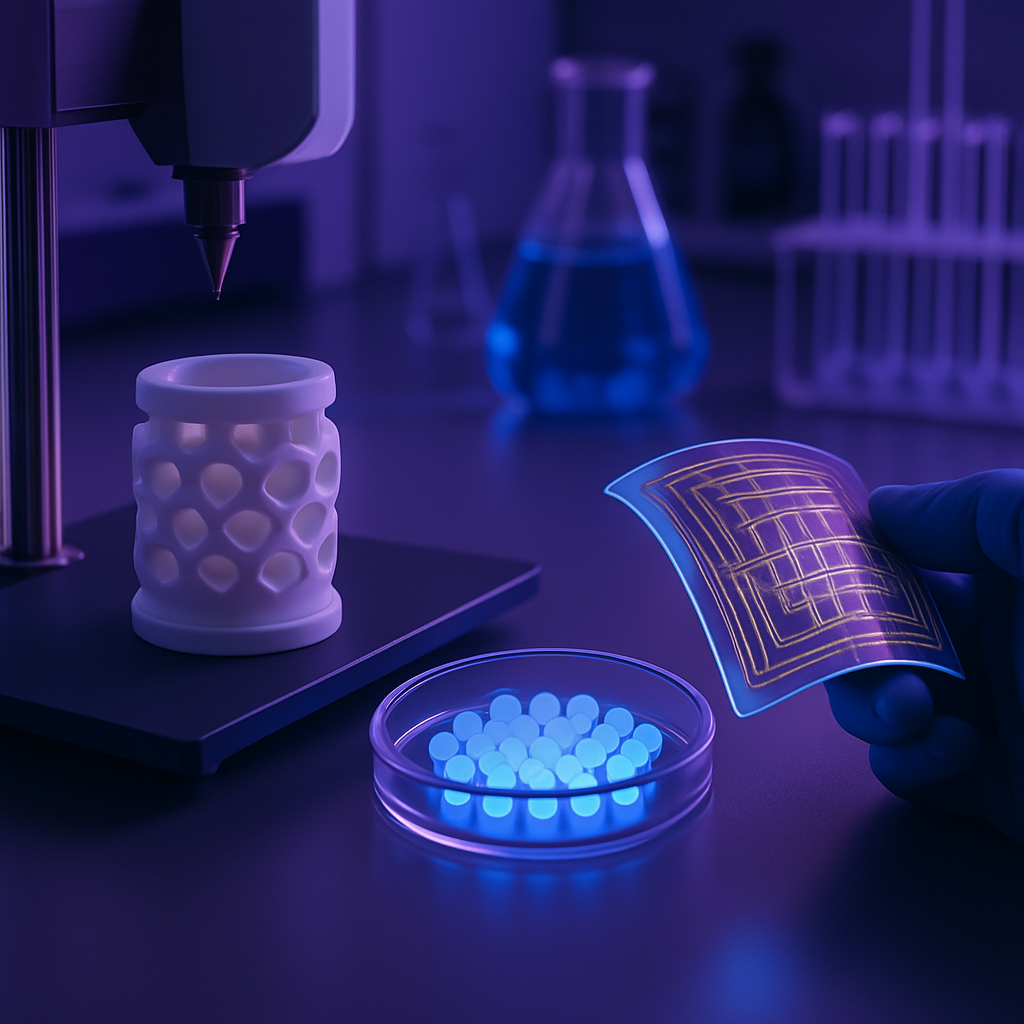

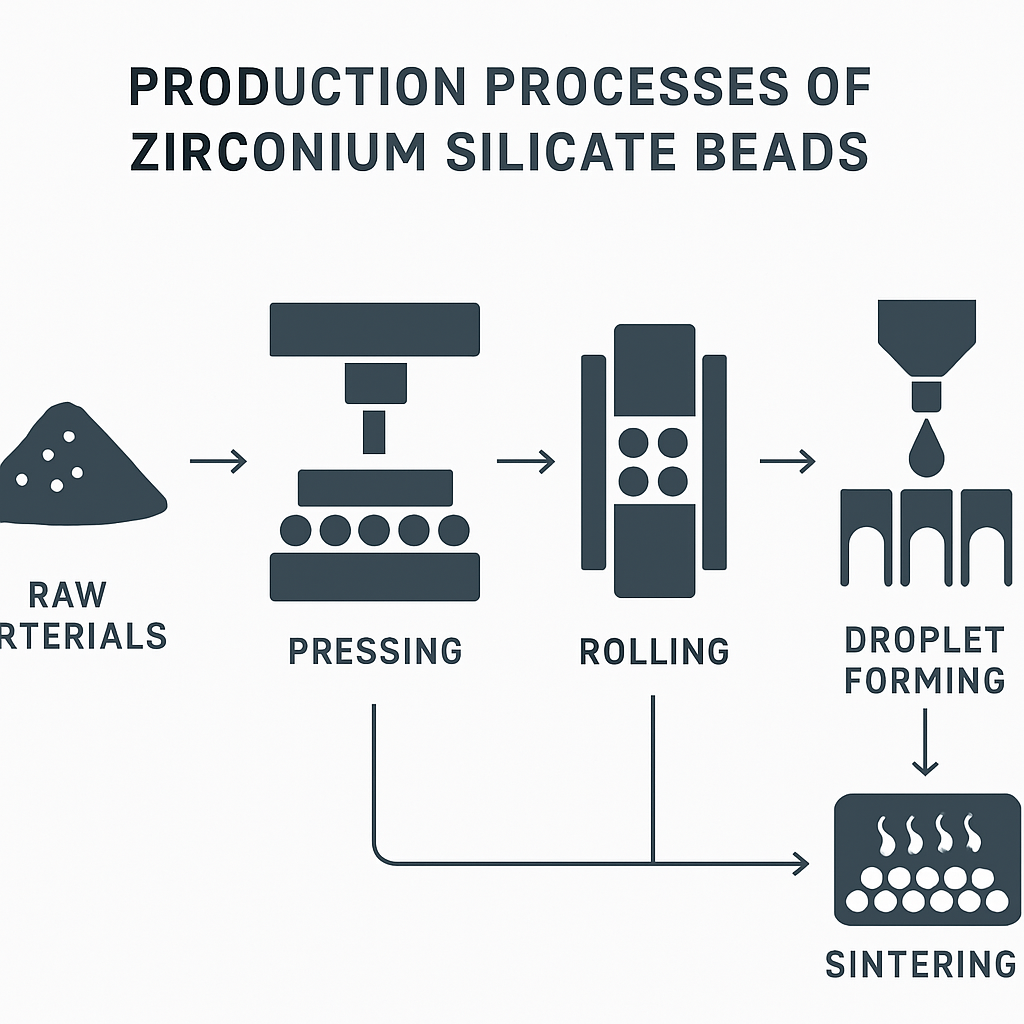

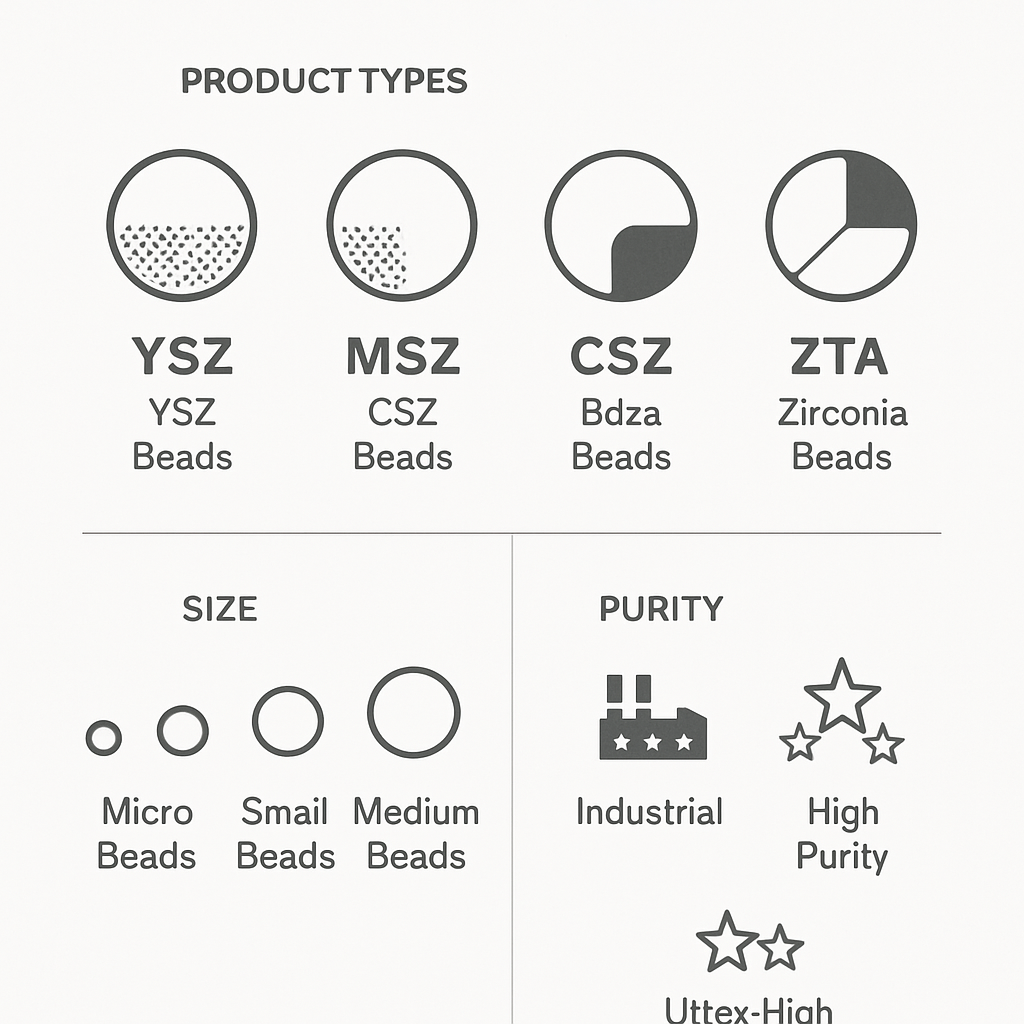

Zirconia beads are high-performance ceramic grinding media manufactured from high-purity zirconium oxide (ZrO₂). Renowned for their ultra-high hardness (Mohs hardness ≥8.5), exceptional wear resistance, and chemical inertness, these beads undergo specialized processes such as yttria stabilization (Y₂O₃-ZrO₂) to achieve stable tetragonal or cubic crystal structures. This ensures physical stability even under extreme conditions (e.g., high temperatures, strong acid/alkali environments), delivering a service life 3-5 times longer than conventional alumina beads.

Key Features:

Excellent chemical resistance

| Product Specification |

|---|

| Chemical Composition |

| ZrO₂ | Y₂O₃ | Other |

|---|---|---|

| ≥95% | ≥4.5% | ≤0.5% |

Note: Different product specifications have different chemical compositions.

| Physical charactenslics |

|---|

| Densily | Bulk Density | Crushing Strength | Vickers Hardness | Wear Rate |

|---|---|---|---|---|

| >6.0g/cm³ | ≥3.7g/cm³ | >2.0KN(Ф2mm) | >1100Hv | <0.5(ppm/h ) |

| Specifications(mm) |

|---|

| Ф0.1-0.2 | Ф0.2-0.3 | Ф0.3-0.4 | Ф0.4-0.6 | Ф0.6-0.8 |

| Ф0.8-1.0 | Ф1.0-1.2 | Ф1.2-1.4 | 1.4-1.6 | Ф1.6-1.8 |

| Ф1.8-2.0 | Ф2.0-2.2 | Ф2.2-2.4 | Ф2.4-2.6 | Ф2.6-2.8 |

| Ф2.8-3.0 | Ф4 | Ф5 | Ф6 | Ф7 |

| Ф8 | Ф10 | Ф12 | Ф15 | Ф17 |

| Ф20 | Ф25 | Ф30 | Ф40 | Ф50 |

Note: Specifications can be customized according to customer needs.

1. Application Scenarios: Used for grinding and dispersing battery materials (such as lithium battery cathode materials), electronic slurries, multilayer ceramic capacitors (MLCC), etc.

Global Industry's zirconium oxide undergoes rigorous 7-stage quality testing to ensure consistent particle size, purity level, and chemical composition batch after batch. Our advanced manufacturing facility maintains strict quality parameters with ±0.5% tolerance, eliminating the production disruptions caused by inconsistent raw materials. Each shipment includes comprehensive material certifications and detailed technical documentation, providing your technical team with complete transparency and confidence in our zirconia's performance characteristics. Our quality control processes are specifically designed to meet the exacting standards of technical ceramics, industrial coatings, and specialty applications.

As a direct manufacturer, we maintain strategic inventory levels of our most popular zirconia grades, reducing standard lead times to just 25 days—significantly below the industry average of 45 days. Our flexible minimum order quantities accommodate both regular production needs and urgent requirements, with options starting from just 500kg. Our dedicated logistics team provides real-time inventory visibility and production capacity updates through our secure client portal, allowing procurement managers to plan with confidence. We offer guaranteed delivery schedules with contractual reliability clauses, backed by our 98.7% on-time delivery record, ensuring your production lines never face costly downtime due to material shortages.

Our in-house technical team includes 6 materials engineers with specialized expertise in zirconium applications across various industries. We provide comprehensive technical support, including custom particle size distribution, specific surface area adjustments, and specialized dopant additions tailored to your exact manufacturing requirements. Our technical consultation service helps optimize material performance while potentially reducing overall costs by 5-12% through precise specification matching. We offer pre-purchase material testing and detailed application recommendations, with technical documentation available in both English and Chinese. Our R&D department continuously develops improved zirconia formulations based on client feedback and industry advancements.

Our factory-direct pricing model eliminates intermediaries, providing clear cost advantages with savings of 8-15% compared to distribution channels. We offer 6-month price stability guarantees to protect your budget planning from market volatility, with transparent explanations of any factors affecting future pricing. Our tiered volume discount structure rewards long-term partnerships with additional cost reductions of 3-7% for annual contracts. We provide detailed cost breakdowns that help procurement teams justify supplier decisions to management, along with customized payment terms that align with your company's financial processes. As your trusted zirconia supplier, we're committed to supporting your cost reduction initiatives while maintaining the premium quality your production demands.