Manufacturers constantly face the pressure of achieving flawless whiteness, exceptional durability, and thermal stability in ceramic products without skyrocketing production costs. The solution lies in the precise application of Zirconium Silicate (ZrSiO₄), an industry-standard material that delivers superior opacity and structural integrity. As a leader in zirconium materials, Global Industry provides the high-purity solutions necessary to meet these rigorous manufacturing standards.

1. What Is the Role of Zirconium Silicate in Ceramic Manufacturing?

Zirconium silicate (ZrSiO₄) is a chemical compound mined primarily from natural zircon sand deposits found in coastal regions like Australia, South Africa, and China. In the ceramic industry, it functions not merely as a raw material but as a critical performance enhancer. When processed into a fine powder, it becomes a chemically inert substance with an extremely high melting point, maintaining stability under the severe conditions of ceramic firing. Here is the deal: it serves a dual purpose, acting as a structural stabilizer in ceramic bodies and as a primary opacifier in glazes.

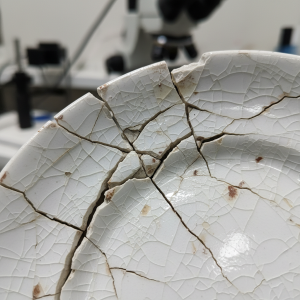

Beyond simple aesthetics, zirconium silicate contributes significantly to the physical integrity of the ceramic piece. It acts as a skeleton within the microstructure, reducing the potential for warping during the firing process. Because it possesses a relatively low thermal expansion coefficient compared to other ceramic raw materials, it helps match the expansion rates of the glaze and the body. This compatibility is vital for preventing defects such as crazing or peeling, ensuring that the final product withstands thermal stress over years of use.

For manufacturers sourcing raw materials, understanding the chemical breakdown is essential.

| Component | Specification (Typical) | Function | |

|---|---|---|---|

| ZrO₂ + HfO₂ | 65% Min | Provides refractoriness and opacity | |

| SiO₂ | 32-34% | Structural silicate matrix | |

| Fe₂O₃ | < 0.1% | Low iron content prevents yellowing | |

| TiO₂ | < 0.15% | Prevents color distortion | |

| Particle Size (D50) | 1-5 µm | Determines opacity efficiency |

2. How Does Application of Zirconium Silicate in Ceramics Enhance Glaze Opacity?

The science behind the pristine whiteness of your ceramic products lies fundamentally in the refractive index. Zirconium silicate possesses a high refractive index (approximately 1.95), while the glassy matrix of a typical glaze has a much lower index (around 1.50). You might be wondering why this matters. The significant difference between these two numbers determines the intensity of light scattering. As light hits the glaze, zirconium particles scatter it in multiple directions rather than letting it pass through, creating a dense, white, opaque finish that effectively covers dark clay bodies.

To maximize this optical effect, the particle size of high-purity zirconium silicate solutions must be strictly controlled. If particles are too coarse, they fail to scatter light efficiently, resulting in a semi-transparent or “milky” appearance. Conversely, if particles are too fine, they may dissolve into the glaze melt, losing their opacifying power entirely. Industry standards typically target a particle size distribution (D50) between 1 to 5 microns to balance optimal opacity with glaze rheology.

Achieving a uniform white finish requires perfect dispersion within the glass matrix. During the firing phase, zirconium silicate crystals must remain evenly distributed throughout the glaze layer. If they agglomerate, the result is uneven shading. Proper milling and the use of dispersants ensure that zirconium particles remain suspended, providing consistent coverage and enhancing the brightness of the final product.

3. Which Methods Are Used to Incorporate Zirconium Silicate into Formulations?

In the production of glazes, wet milling is the predominant method for incorporation. Zirconium silicate is introduced into ball mills alongside feldspar, quartz, kaolin, and water. But here is the catch: the timing of addition is critical. Since zirconium is extremely hard (Mohs 7.5), it is often added towards the end of the milling cycle if pre-ground zircon flour is used, ensuring the glaze slurry achieves a homogenous consistency without over-grinding softer raw materials.

For ceramic bodies, such as porcelain stoneware, dry mixing or continuous wet grinding is employed. In these applications, zirconium silicate is often added to the spray-dried powder mixture. The goal here is to distribute the material evenly throughout the bulk of the ceramic body to enhance its whiteness and mechanical strength. This is particularly important for unglazed polished tiles, where the “super-white” body aesthetic is a key selling point for high-end architectural projects.

Another advanced method involves incorporating zirconium silicate directly into ceramic frits. In this process, raw materials are melted together and then quenched to form glass granules. By pre-dissolving or encapsulating zirconium within the frit, manufacturers can achieve better melting behavior and reduce the risk of surface defects like pinholes. This method is generally more expensive but offers superior control over the final glaze surface quality.

| Method | Application | Key Advantage | |

|---|---|---|---|

| Wet Ball Milling | Sanitaryware Glazes | Ensures smooth, defect-free surface finish | |

| Dry Blending | Tile Bodies | Uniform bulk whiteness for polished tiles | |

| Frit Melting | High-end Glazes | Pre-reacts components to lower melting temperature | |

| Jet Milling | Ultrafine Opacifiers | Creates nano-scale particles for maximum efficiency |

4. What Physical Properties Does Zirconium Silicate Impart to Ceramics?

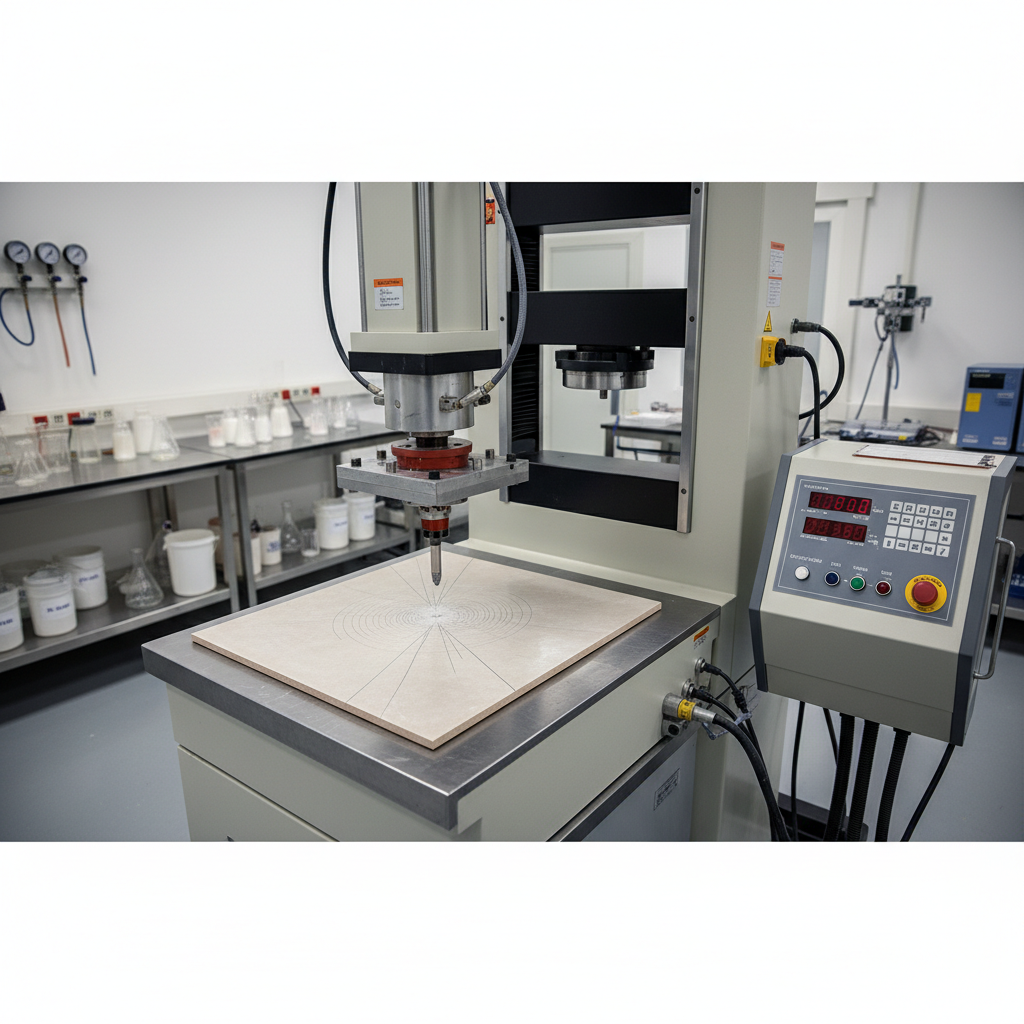

One of the most valuable attributes of zirconium silicate is its hardness. Scoring 7.5 on the Mohs scale, it is significantly harder than quartz and most other glaze constituents. What does this mean for you? When added to a glaze, particularly for floor tiles, it dramatically improves the abrasion resistance (PEI rating). This makes the surface capable of withstanding heavy foot traffic without losing its gloss or developing scratches, extending the operational lifespan of the installation.

Zirconium silicate is chemically inert, meaning it resists attack from acids, alkalis, and staining agents. In the context of micronized zircon powder , this inertness is transferred to the ceramic glaze. A zirconium-enriched surface is far less porous and chemically reactive, making it ideal for laboratory surfaces, kitchen countertops, and hospitals where harsh cleaning chemicals are frequently used. It ensures that the ceramic maintains its hygiene and appearance over decades of use.

Controlling the Coefficient of Thermal Expansion (CTE) is vital to preventing ceramic failure. Zirconium silicate has a relatively low CTE. By adjusting the percentage of zircon in a glaze formulation, ceramists can fine-tune the expansion fit between the glaze and the clay body. If the glaze expands and contracts at a similar rate to the body, it remains under slight compression, preventing crazing (a network of fine cracks) and shivering (peeling off), ensuring structural reliability.

5. Where Is Zirconium Silicate Applied in Sanitary Ware and Tiles?

In the sanitary ware sector, appearance is everything. Toilets, bidets, and sinks utilize thick, glossy, white glazes that must look immaculate. Zirconium silicate is the standard opacifier here because it delivers a clean, neutral white that consumers associate with hygiene. It effectively masks the off-white or tan color of the vitrified clay body. Furthermore, the chemical resistance provided by zirconium ensures that these fixtures withstand daily exposure to water, lime scale removers, and biological waste without degrading.

For the tile industry, zirconium silicate is versatile. It is used in engobes—the intermediate layer between the tile body and the glaze—to provide a white canvas and ensure proper adhesion. In the top glaze of floor tiles, it serves a functional role by enhancing hardness. It gets better: for “super white” polished porcelain tiles, zirconium is added directly to the body mixture. This allows the tile to be polished to a mirror finish while maintaining a consistent white color throughout its thickness.

Beyond standard white, zirconium silicate is essential for stabilizing colored glazes. It acts as a host lattice for certain ceramic pigments (like Vanadium Zircon Blue or Praseodymium Zircon Yellow). By stabilizing these colorants, it allows for vibrant, consistent hues that do not burn out at high firing temperatures. This versatility makes it indispensable for tile manufacturers who need to offer a wide range of aesthetic options while maintaining technical performance.

| Application | Function | Benefit | |

|---|---|---|---|

| Sanitary Ware | Top Glaze Opacifier | Provides “hygienic white” look and chemical resistance | |

| Floor Tiles | Glaze Hardener | Increases scratch resistance (Mohs 7.5) | |

| Wall Tiles | Engobe Layer | Masks dark body color, improves glaze fit | |

| Porcelain Slabs | Body Whitener | Allows for consistent color in polished cross-sections |

6. Why Is Zirconium Silicate Essential for Refractory Applications?

While glazing focuses on aesthetics, the refractory industry utilizes premium zircon sand raw materials for sheer survival in extreme heat. Zirconium silicate does not dissociate until temperatures exceed 1540°C, and its melting point is much higher. This makes it an ideal material for bricks, mortars, and castables used in glass melting furnaces and steel ladles. It withstands the intense thermal environment without softening or losing structural strength.

In glass manufacturing, the corrosion of furnace linings is a major cost driver. Zircon refractories are uniquely resistant to wetting and corrosion by molten silicate glass. Here is the secret: because zircon is chemically compatible with glass, it dissolves very slowly compared to other refractory materials. This extends the campaign life of glass furnaces significantly. Similarly, in steel and aluminum foundries, zircon washes are used to coat molds because molten metal does not stick to them, ensuring clean castings with good surface finish.

Refractory materials are often subjected to rapid temperature swings. Zirconium silicate has excellent thermal shock resistance due to its low and uniform thermal expansion. This means that a zircon brick can cycle between hot and cold zones in a kiln without cracking or spalling. This reliability is critical for kiln furniture—the shelves and posts used to support ceramic ware during firing—ensuring that the support structure does not fail and ruin the production load.

7. What Challenges Arise in Application of Zirconium Silicate in Ceramics?

Adding high percentages of solid particles like zirconium silicate to a glaze slurry can drastically alter its flow properties. Here is the challenge: zircon has a high density, which can lead to rapid settling in the glaze bucket or tank if not properly suspended. If the slurry settles hard, it becomes like concrete at the bottom of the container. Furthermore, excessive loading can increase viscosity, making the glaze application uneven or causing it to “crawl” (pull away) from the ceramic surface during firing.

Zirconium silicate is a premium raw material, significantly more expensive than feldspar or silica. Its price is tied to global mining output and demand from competing sectors. Manufacturers must balance the need for high opacity with the imperative to control costs. Using too much zircon eats into margins, while using too little compromises quality. This necessitates precise formulation and often leads manufacturers to seek finer milling grades that offer better coverage at lower percentages.

The quality of the final ceramic product is heavily dependent on the purity of the zirconium silicate. Natural zircon sand often contains trace impurities like iron oxide (Fe2O3) and titanium dioxide (TiO2). Even small amounts of iron can cause yellowing or black specks in a white glaze, ruining the aesthetic. Therefore, sourcing beneficiated zircon that has undergone magnetic separation and washing is critical to preventing widespread defects.

8. How Does Zirconium Silicate Compare to Other Ceramic Opacifiers?

Historically, tin oxide was the king of opacifiers. It produces a buttery, soft white that is unmatched in quality. However, here is the reality: tin oxide is prohibitively expensive, costing many times more than zirconium silicate. While tin is more effective pound-for-pound, the price difference makes zirconium the only viable option for mass industrial production. Zircon provides a cooler, sharper white compared to tin, which is generally preferred in modern sanitary ware designs.

Titanium dioxide (TiO2) is another strong opacifier used in enamels and some glazes. While it is effective, it has a significant drawback: color instability. Titanium tends to crystallize in ways that can turn a glaze yellowish or interact with trace iron to create distinct discoloration. It also promotes a matte surface texture, which may not be desirable for glossy sanitary ware. Zirconium silicate, by contrast, is chemically stable and maintains a neutral white color and high gloss, making it more reliable for consistent large-scale manufacturing.

Calcined alumina is sometimes used to increase the durability and whiteness of a glaze, often used in conjunction with zircon. While alumina improves hardness and scratch resistance, it is not a true opacifier in the same sense. It does not scatter light as efficiently as zirconium silicate. Using alumina alone results in a semi-opaque or matte finish rather than a bright opaque white. Therefore, zirconium silicate remains the primary choice for opacity, while alumina serves as a supplementary hardener.

| Opacifier | Cost | Opacity Efficiency | Color Tone | |

|---|---|---|---|---|

| Zirconium Silicate | Moderate | High | Neutral Cool White | |

| Tin Oxide | Very High | Very High | Warm Soft White | |

| Titanium Dioxide | Moderate | High | Yellowish/Creamy | |

| Alumina | Low | Low | Matte/Translucent |

9. What Factors Influence the Cost and Quality of Zirconium Silicate?

The price of zirconium silicate is directly linked to how finely it has been processed. You get what you pay for: ultrafine powders (e.g., 1 micron) require significantly more energy and time to mill, commanding a higher price premium. However, these finer grades offer far superior opacifying power, meaning a manufacturer can use less of the material to achieve the same result. Balancing the cost of the raw material against the usage rate is a key calculation for ceramic formulators.

Natural zircon sand contains trace amounts of uranium and thorium, making it slightly radioactive. Strict regulations govern the transport and handling of NORM (Naturally Occurring Radioactive Materials). High-quality zirconium silicate undergoes processing to ensure these levels are well within safe industrial limits. Compliance with environmental and safety standards adds to the production cost but is non-negotiable for advanced ceramic structural components utilized in consumer goods.

The supply of zircon is concentrated in a few major mining regions. Disruptions in these areas, whether due to geopolitical issues or mining quotas, can cause price spikes globally. Additionally, the energy costs associated with mining, transport, and milling play a huge role. B2B buyers must track these global trends to secure stable pricing contracts and ensure that their production lines are not stalled by material shortages.

10. What Is the Future Outlook for Zirconium Silicate in the Ceramic Industry?

The frontier of ceramic science lies in nanotechnology. Research is currently focused on producing nano-sized zirconium silicate particles. Imagine the possibilities: particles so small that they scatter light with near-perfect efficiency, allowing for ultra-thin glaze layers that reduce material consumption by huge margins. These advancements could revolutionize the cost structure of ceramic production, making high-quality finishes accessible at lower price points while maintaining the superior properties of zirconium.

As the ceramic industry faces pressure to reduce its environmental footprint, recycling zirconium-rich waste is becoming a priority. Technologies are being developed to recover zirconium silicate from fired ceramic waste (pitchers) and polishing sludge. Reintroducing this reclaimed material into the production cycle reduces the reliance on virgin mining and lowers the carbon footprint associated with transport and processing. This circular economy approach is set to define the next decade of material sourcing.

While traditional tiles and sanitary ware remain the volume leaders, specialized zirconia applications are growing in the technical sector. Zirconium silicate’s thermal and electrical insulation properties are being leveraged for advanced electronic substrates and 5G communication components. As these high-tech industries expand, the demand for high-purity, specialized grades of zirconium silicate will likely increase, driving further innovation in purification and processing techniques.

Conclusion

Zirconium silicate remains an irreplaceable asset in the ceramic industry, bridging the gap between aesthetic perfection and structural durability. Its unique ability to provide brilliant opacity while enhancing chemical and mechanical resistance makes it the material of choice for tile and sanitary ware manufacturers worldwide. As the industry evolves toward sustainability and high-tech applications, the processing and application of this versatile mineral will continue to advance. For manufacturers looking to secure their supply chain or optimize their formulations, partnering with a reliable supplier is crucial. Contact us today to discuss your specific requirements and discover how our premium zirconium solutions can elevate your production quality.

FAQ

Q1: What is the ideal particle size for Zirconium Silicate in glazes?The ideal particle size typically ranges from 1 to 5 microns (D50). Finer particles (around 1 micron) offer superior opacity and whiteness, allowing for lower percentage loading in the glaze formulation, while slightly coarser grades may be used where cost is a primary constraint or specific textures are desired.

Q2: How does Zirconium Silicate affect the firing temperature of ceramics?Zirconium silicate is highly refractory, meaning it has a very high melting point. It generally acts as a stabilizer and does not act as a strong flux. Therefore, adding high percentages can stiffen the glaze melt, potentially requiring a slight increase in firing temperature or the addition of more fluxing agents to ensure a smooth, defect-free surface.

Q3: Can Zirconium Silicate be used in colored glazes?Yes, it acts as a base for pastel colors. While it whitens and opacifies, it can be mixed with stains to create stable, uniform pastel shades. Furthermore, it acts as a crystal host for specific high-temperature pigments, such as Praseodymium Yellow and Vanadium Blue, protecting the color at high heat.

Q4: Is Zirconium Silicate safe to use regarding radioactivity?Yes, commercial-grade zirconium silicate is processed to ensure that Naturally Occurring Radioactive Materials (NORM) are within safe regulatory limits for industrial and consumer use. While raw zircon sand has trace radioactivity, the refined powders used in ceramics are safe for workers and end-users when handled according to standard safety protocols.

Q5: What is the typical percentage of Zirconium Silicate added to a white glaze?For a standard white opaque glaze used in sanitary ware or tiles, the loading of zirconium silicate typically ranges between 8% to 15% by weight. The exact percentage depends on the desired level of whiteness, the particle size of the zircon, and the thickness of the glaze application.