Understanding how to choose zirconia-stabilized refractories is crucial for industries that encounter high temperatures and corrosive environments. The primary concern for many purchasing managers is whether to use MgO-PSZ or YSZ, as this decision can significantly impact either the longevity or failure of lining materials. This article addresses those concerns by comparing these two types of refractories in detail. You will discover the characteristics that set them apart, ultimately providing insights that aid you in making informed decisions for your operations.

Stabilizing zirconia is essential because unmodified ZrO₂ experiences phase transformations during cooling, leading to issues like volume expansion and cracking. The role of stabilizers such as MgO, CaO, and Y₂O₃ is to lock the more stable tetragonal or cubic phases in place, thereby enhancing performance and durability. In this article, you will learn why utilizing these stabilizers effectively can greatly influence refractory lining outcomes.

Why Must Zirconia Be Stabilized?

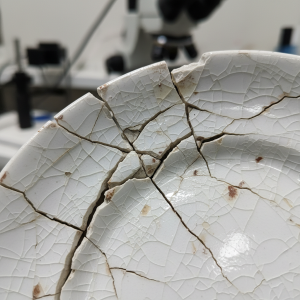

Zirconia, or ZrO₂, is known for its impressive properties, but it has a significant drawback. As ZrO₂ cools from high temperatures, it undergoes phase transformations that can lead to volume expansion and cracking. This instability can dramatically affect its performance in applications where thermal and structural integrity is crucial.

To combat this issue, engineers usually employ stabilizers such as MgO (magnesium oxide), CaO (calcium oxide), and Y₂O₃ (yttrium oxide). The primary goal of these stabilizers is to alter the phase behavior of the zirconia during cooling, ensuring that the material holds its shape and properties. When properly stabilized, zirconia can endure the high temperatures that come with industrial applications without suffering damage.

The choice of stabilizer is paramount. Among the common options, YSZ is increasingly gaining traction as the superior high-performance system. Understanding these dynamics is essential for professionals looking at long-term solutions for their operations, especially in industries dealing with extreme conditions, such as metals, glass, or ceramics production. If you need a broader framework for comparing different zirconia grades and dopants, read our guide on how to choose the best zirconia material for your application.

Effective stabilization not only improves the mechanical properties of zirconia but also enhances its thermal shock resistance. This is vital in processes involving drastic temperature changes, where other materials may fail. Investing time and resources to choose the right stabilizer will ultimately lead to increased operational efficiency and reduced downtime.

How Does Stabilizer Type Impact Refractory Performance?

What really makes a difference is the type of stabilizer you choose. Each stabilizer affects zirconia’s thermal stability and overall performance. For instance, different stabilizers provide different phase stability windows, significantly impacting performance metrics such as thermal shock resistance and corrosion resistance.

The operational environment plays a critical role in determining which stabilizer is appropriate. The corrosion resistance and thermal shock behavior can vary dramatically among stabilizers. For example, YSZ typically exhibits superior overall stability due to its unique thermal and chemical properties. This leads to better performance in fluctuating high-temperature conditions.

Moreover, the thermal expansion rates differ depending on the stabilizing agent. MgO tends to have a lower thermal expansion coefficient than CaO. This can affect how the refractory material interacts with the underlying structure or components in high-temperature applications. Gradual expansions can lead to less stress in the lining materials, contributing to a longer service life.

When purchasing refractory products, it’s crucial to consider the chemistry of the stabilizers employed, as this will dictate their suitability for specific furnace conditions. Knowledge of how these elements work can guide decision-makers toward the most advantageous choice for their operational needs.

| Stabilizer Type | Phase Stability | Thermal Shock Resistance | Corrosion Resistance |

|---|---|---|---|

| MgO | Moderate | High | Moderate |

| CaO | Moderate | Moderate | High |

| Y₂O₃ | High | High | Very High |

Understanding these differences is essential for selecting the right materials for your production processes. Each stabilizer has distinct characteristics, making it vital to match the material to specific operational parameters.

What Makes MgO-PSZ a Tough Choice for Refractories?

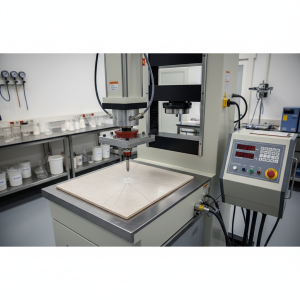

MgO-PSZ, or Magnesium Oxide-Partially Stabilized Zirconia, is often regarded as the champion in toughness and thermal shock resistance. Its excellent thermal shock resistance allows it to survive drastic changes in temperature without cracking.

This characteristic is crucial in industries that deal with rapid temperature fluctuations, such as steelmaking, where refractories are exposed to hot metal and then rapidly cooled. In such environments, the ability of a material to withstand thermal stress and maintain structural integrity can significantly impact productivity. If you are also evaluating zirconia-based structural ceramics beyond refractories, our in-depth guide on zirconia ceramics as “ceramic steel” shows how toughness and thermal stability translate into real industrial components.

One of the key features of MgO-PSZ is its high fracture toughness. This quality results from classical PSZ microcrack toughening, which helps in absorbing stress and preventing rapid fracture. The microcracks formed during the toughening process can help to deflect crack propagation, minimizing the risk of extensive damage.

Because of these properties, MgO-PSZ is well-suited for environments where rapid heating and cooling cycles occur. Additionally, it can withstand mechanical impacts that might damage other refractory materials.

However, it’s worth noting that while MgO-PSZ excels in specific applications like steelmaking and foundry environments, its chemical resistance might limit its performance in aggressive slag systems. Operators using MgO-PSZ in such conditions should monitor it closely, as prolonged exposure to corrosive materials can result in unexpected failure.

| MgO-PSZ Characteristics | Benefits in Service | Best Applications |

|---|---|---|

| Excellent thermal shock | Survives rapid cycles | Steelmaking |

| High fracture toughness | Withstands mechanical impacts | Foundries |

| Good thermal stability | Ideal for extreme temperatures | Impact zones |

By understanding both the advantages and limitations of MgO-PSZ, professionals can make better choices regarding their refractory selections. This awareness helps manage expectations and can lead to more reliable operations.

How Does CaO-PSZ Provide Stability During High-Temperature Operation?

CaO-PSZ, or Calcium Oxide-Partially Stabilized Zirconia, offers distinct advantages that make it suitable for high-temperature applications. One defining feature is its high structural stability above 1600°C. This allows CaO-PSZ to maintain its integrity during extended periods of high heat, which is essential in industries that require long-duration operations.

Unlike other stabilizers, CaO-PSZ is less prone to phase degradation under long-term exposure to severe temperatures. Therefore, it has become a preferred choice for applications where constant heat is applied, such as in glass production or in certain types of kilns.

Additionally, CaO-PSZ performs exceptionally well in alkaline environments and resists corrosion from glassy or vapor phases. This dual resistance is significant as many industrial processes expose materials to harsh conditions.

However, while its performance in consistently high-temperature applications is commendable, CaO-PSZ does face challenges regarding ultimate corrosion resistance when compared to other options. Specific conditions, such as exposure to acidic slag or highly reactive materials, can lead to degradation over time.

Thus, while it excels in stable environments, the aggressive nature of certain slag systems should be considered when selecting refractory materials.

| CaO-PSZ Characteristics | Advantages in Service | Best Applications |

|---|---|---|

| High structural stability | Performs well in alkaline conditions | Glass tanks |

| Less prone to degradation | Resists glass or vapor-phase corrosion | Gasifiers |

| Ideal for high temperatures | Stands up during long soaks | Continuous high-temperature linings |

Choosing CaO-PSZ can offer crucial benefits, but thorough evaluation of the operational environment is necessary to avoid potential pitfalls. Managers need to align their choices with project requirements.

What Sets YSZ Apart as the Superior Refractory Performer?

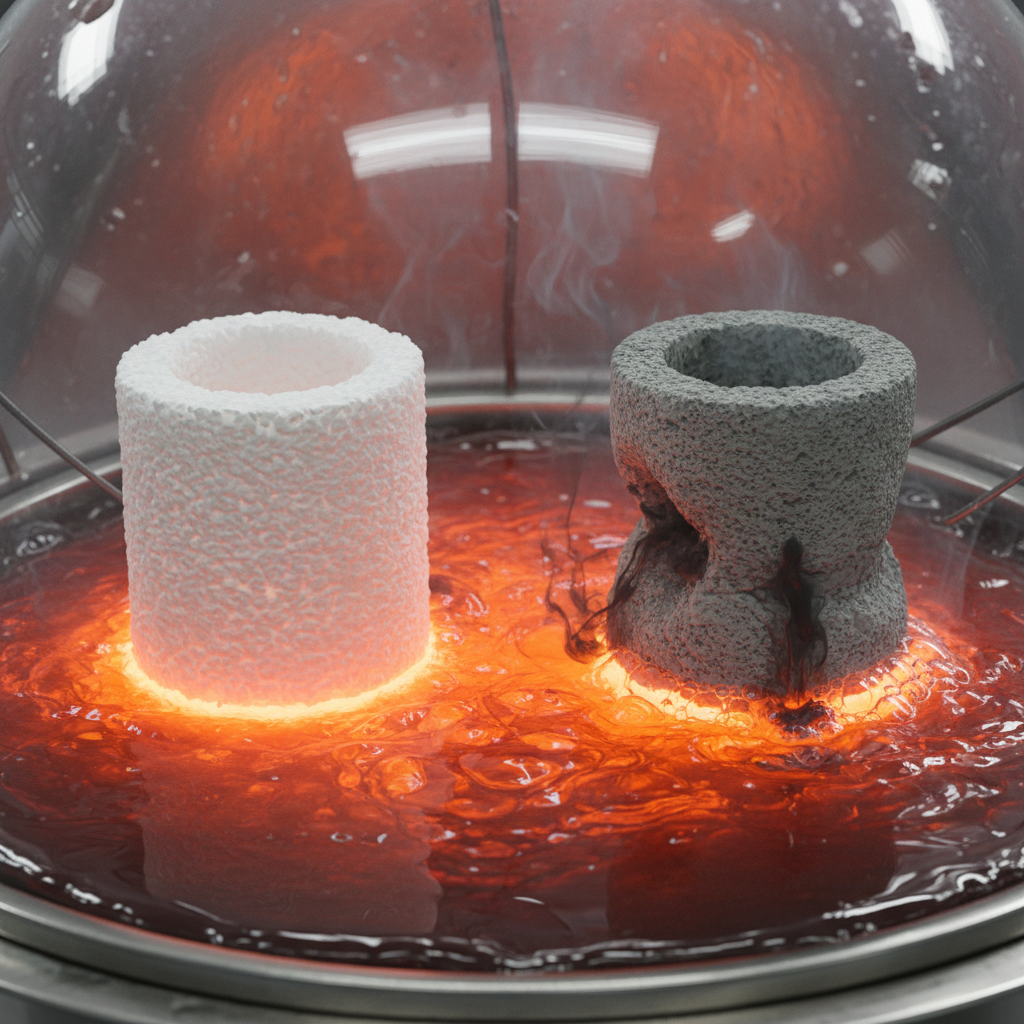

Now, let’s focus on YSZ, the highlight of this discussion. YSZ, or Yttria-Stabilized Zirconia, stands out for its unique chemical stability and exceptional performance metrics.

One key advantage of YSZ is that Y₂O₃ remains chemically inert in most slag systems. This helps minimize reactions that can compromise structural integrity. In contrast, MgO and CaO can react with acidic or amphoteric slags, leading to premature failure. This quality makes YSZ an ideal choice in environments where slag composition can vary widely.

Furthermore, YSZ exhibits the highest phase stability across temperature cycles, significantly reducing the risk of t → m degradation. This property offers peace of mind for facilities that experience temperature fluctuations as part of their daily operations.

YSZ also boasts ultra-low thermal conductivity, which is significantly lower than that of MgO- or CaO-based systems. This characteristic enhances thermal insulation and energy efficiency, resulting in lower operational costs over time. In many cases, companies have reported improved energy savings due to the superior insulating properties of YSZ.

The balance of toughness, corrosion resistance, and phase stability positions YSZ as a top contender for anyone seeking a reliable refractory solution. That said, it does come with a higher upfront cost. However, the return on investment is evident in its long lifespan and performance in mission-critical applications.

When evaluating refractory materials for high-performance applications, it’s critical to weigh the initial costs against long-term savings in maintenance and operational efficiency.

| YSZ Characteristics | Performance Advantages | Considerations |

|---|---|---|

| Chemical stability | Unmatched slag resistance | Higher initial cost |

| High phase stability | Reliable under temperature fluctuations | ROI in long-life applications |

| Ultra-low thermal conductivity | Enhances insulation and efficiency | Ideal for critical zones |

Taking all these factors into account can lead to significant improvements in performance, safety, and economic viability in refractory applications.

How Can Professionals Quickly Select the Right Refractory?

Choosing the right refractory material is vital for operational success. Here’s a quick selection guide to streamline the process.

- Need maximum toughness and thermal shock? Choose MgO-PSZ.

- Need long-term structural stability at very high temperatures? Opt for CaO-PSZ.

- Need superior corrosion resistance, phase stability, and the lowest thermal conductivity? Go with YSZ.

This guide provides a simplified way for purchasing managers to weigh their options based on specific application needs. Understanding these distinctions can significantly aid in decision-making and ultimately lead to better performance in demanding environments.

Besides the operational characteristics, it’s worth mentioning the importance of reliable suppliers. The quality of materials can vary widely, and partnering with reputable manufacturers ensures the consistency and reliability of refractory products.

| Selection Needs | Recommended Refractory |

|---|---|

| Maximum toughness | MgO-PSZ |

| Long-term stability | CaO-PSZ |

| Superior corrosion resistance | YSZ |

Being well-informed on the performance characteristics and potential limitations of each type can guide your team toward making the best decisions that align with your operational goals.

Why Is the Industry Shifting Towards YSZ?

As industries evolve, so do their needs. One underlying trend is the increasing aggression of slag systems and the demand for higher operating temperatures and longer durations. With the stakes so high, downtime can prove costly, making reliability critical in refractory engineering.

The shift towards YSZ is indicative of a broader trend in the industry. Operations that rely on refractory materials are recognizing the long-term benefits of investing in higher-quality substances, even at a higher upfront cost.

This brings us back to performance. YSZ provides unmatched stability, durability, and corrosion resistance, making it an increasingly attractive choice for businesses looking to optimize their operations. It meets the rigorous demands of modern manufacturing and processing environments, where durability and efficiency cannot be compromised.

As you assess your production needs, remember that investing in quality materials like YSZ has the potential to yield substantial returns in performance, safety, and compliance.

In modern refractory engineering, the stabilizer determines the entire system’s performance, and YSZ is leading the way. With its superior properties, it offers a comprehensive solution for high-performance applications, setting a new standard in the industry.

Conclusion

In sum, understanding the distinctions among zirconia-stabilized refractories like MgO-PSZ, CaO-PSZ, and YSZ is crucial for making informed decisions in high-temperature environments. The highlight is YSZ’s ability to deliver exceptional durability and efficiency, resulting in lower operational costs over time. Partner with Global Industry to learn more about optimizing your refractory material choices. Together, we can ensure your business thrives.

FAQ Section

Q1: What does stabilizing zirconia entail?

Stabilizing zirconia involves adding specific oxides to maintain its desired phase structure during temperature changes, preventing cracking and degradation.

Q2: How does YSZ compare to MgO-PSZ and CaO-PSZ in terms of cost?

While YSZ generally incurs higher material and processing costs, its long lifespan and reliability in demanding environments provide better return on investment.

Q3: In what environments do MgO-PSZ refractories thrive?

MgO-PSZ refractories excel in environments with rapid temperature changes, making them ideal for steelmaking and foundries.

Q4: Why is chemical resistance significant in refractory applications?

Chemical resistance is vital as aggressive environments can lead to faster degradation of refractory materials, impacting operational efficiency and safety.

Q5: Which refractory type should businesses choose for fluctuating high temperatures?

For fluctuating high-temperature conditions, YSZ offers unmatched stability, reliability, and longevity, making it the best choice among refractory options.