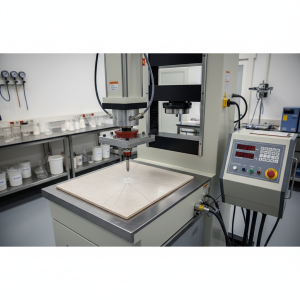

Imagine a high-volume ceramics production line running at full capacity. The kilns are firing at 1200°C, the spray robots are moving in sync, but suddenly, the glaze slurry stops flowing evenly. It begins to streak, or worse, it applies too thinly on vertical surfaces and too thickly on horizontal ones. This inconsistency isn’t just a minor nuisance; it leads to skyrocketing rejection rates, wasted tons of expensive raw materials, and critical downtime that drains your quarterly profitability.

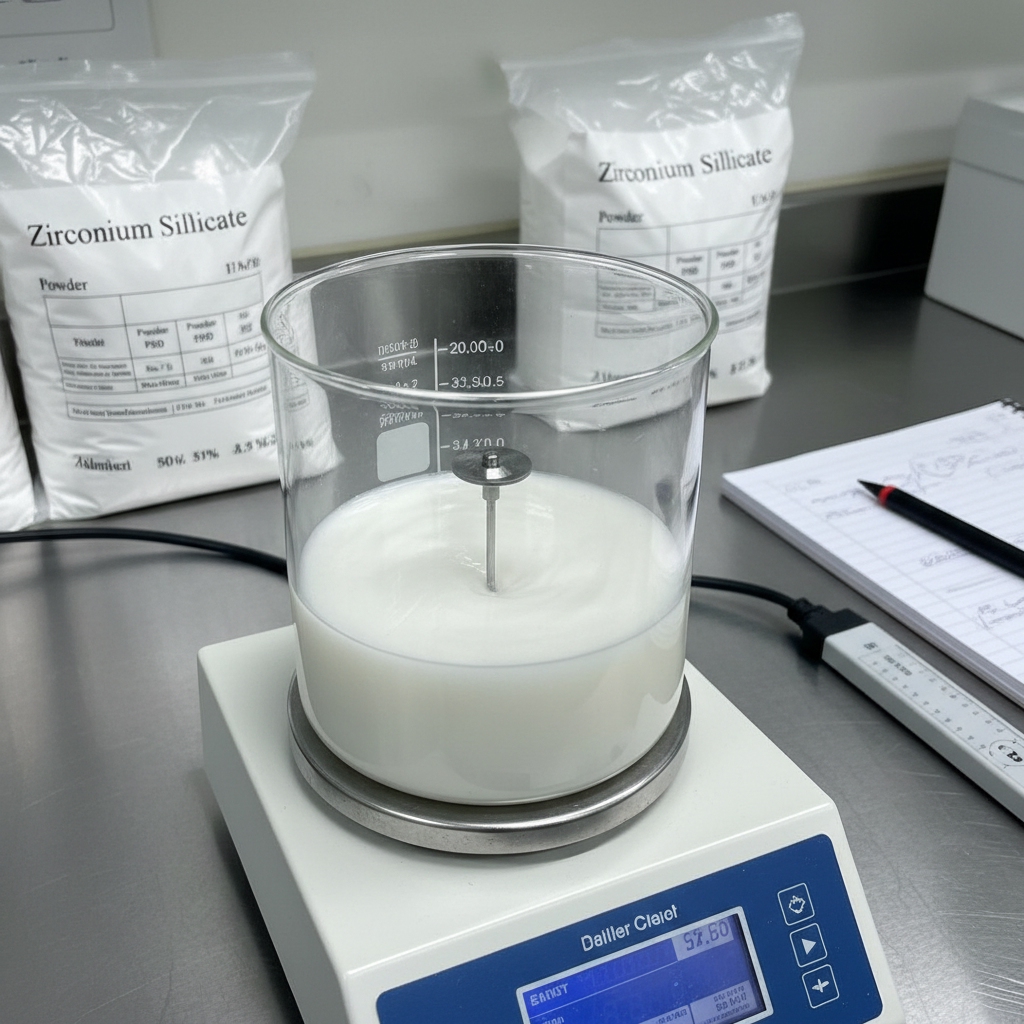

In an industry where margins are dictated by “first-time quality” yields, the difference between a flawless A-grade piece and a scrap heap often comes down to the microscopic properties of your raw materials. The hidden lever controlling this chaos is often the Zircon Powder PSD (Particle Size Distribution). While chemical purity gets all the attention, it is the physical geometry of the particles—the distribution of sizes—that dictates the fluid dynamics of your suspension. When optimized, PSD stabilizes rheology for flawless application; when ignored, it renders even the most expensive glaze formulations unworkable.

How Does Zircon Powder PSD Alter Glaze Rheology?

The distribution of particle sizes directly dictates the internal friction, colloidal stability, and flow resistance within your glaze slurry. Rheology—the study of how matter flows—is not just about how “thick” a liquid is; it is about how that liquid reacts to force. Here is the deal, controlling the Zircon PSD is the first step toward predictable production because Zircon often makes up a significant percentage of the solids in an opacified glaze.

How does viscosity shift with size?

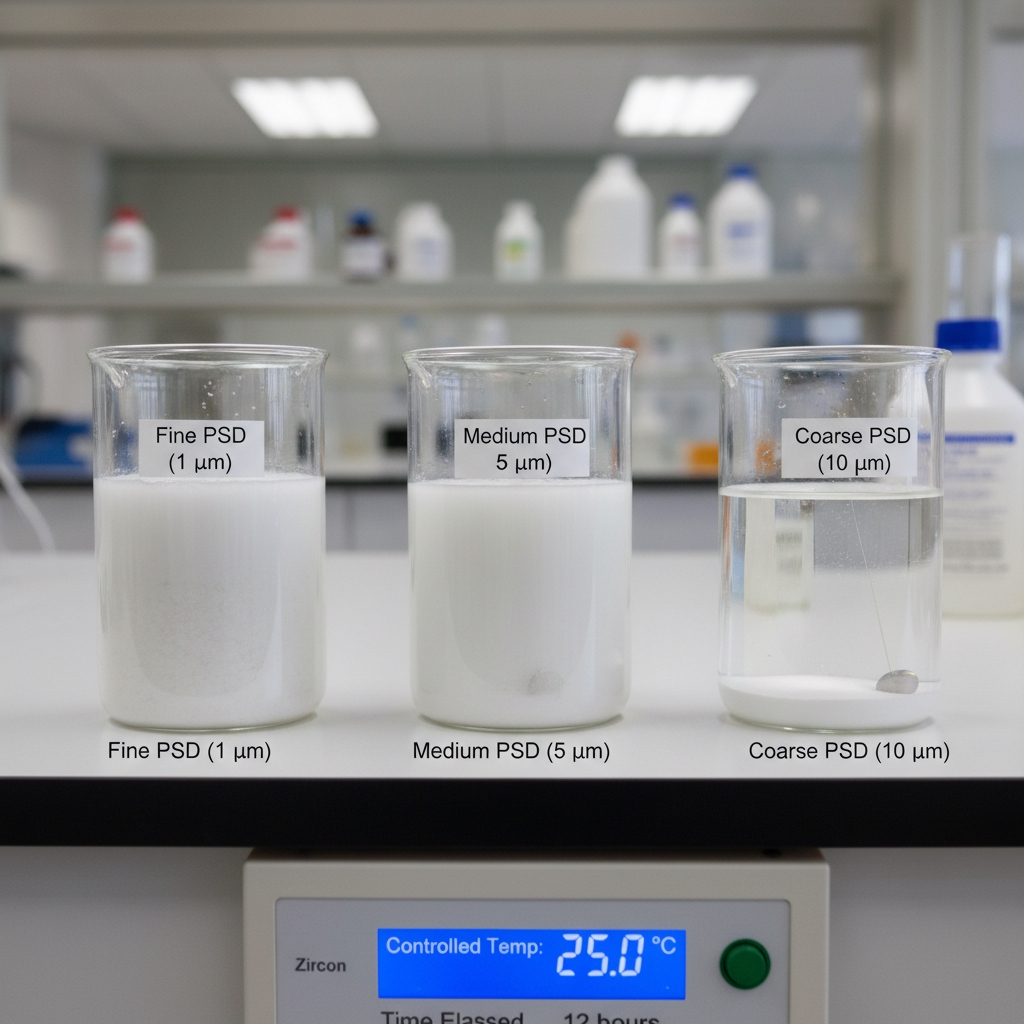

Viscosity in ceramic slurries is primarily a function of surface area. Finer particles have a massive surface-area-to-volume ratio compared to coarse particles.

- High viscosity (Fine particles): As you grind zircon finer (increasing surface area), the electrical charges on the particle surfaces interact more intensely with the water and the binder system. This demands more water to achieve the same fluidity, driving up viscosity significantly if the water content is fixed.

- Low viscosity (Coarse particles): Coarser distributions have less total surface area and lower inter-particle friction, resulting in a slurry that flows more like water but lacks suspension stability.

- Shear thinning behavior: Optimized PSD fosters “pseudoplasticity,” where the glaze is thick when at rest (preventing settling) but becomes thin and fluid when agitated or sprayed.

What if yield stress fails?

Yield stress is the minimum force required to make the slurry move. If yield stress is too low due to an improper PSD (usually a lack of sufficient fines to create a structure), the glaze will run off vertical surfaces immediately after spraying. Conversely, if it is too high, the glaze won’t level out, leaving “orange peel” textures.

Key Takeaway: You must balance fine and coarse fractions to maintain suspension without sacrificing flow. You need fines to build the structure (yield stress) and coarse particles to reduce drag (viscosity).

| PSD Factor | Rheological Impact | Practical Consequence | |

|---|---|---|---|

| High Fines | Increased Viscosity | Requires more water; higher drying shrinkage. | |

| High Coarse | Reduced Suspension | Rapid settling; glaze runs off vertical walls. | |

| Broad Distribution | Lower Viscosity | Better packing; flows easily at higher densities. |

Monitoring these shifts allows you to predict application behavior before the glaze hits the kiln, shifting from reactive troubleshooting to proactive engineering.

What Properties Define Zircon Powder PSD Quality?

Quality in Zircon powder isn’t just about the average particle size; it depends on the consistency of the curve width (the span) and the chemical purity interacting with the particle geometry.

How does particle shape matter?

The manufacturing process determines particle morphology. Spherical particles flow better than irregular shards because they roll over one another, reducing the energy needed for application. But here is the kicker, irregular shapes with sharp edges often result from cheaper, high-impact milling processes. These jagged particles interlock, artificially increasing viscosity and causing inconsistent flow rates through spray nozzles.

What defines the distribution width?

The “Span” of the distribution describes how wide the bell curve is.

- Narrow span (Uniform melt): A tight distribution means most particles are the same size. This ensures they all melt or react at the exact same moment in the kiln, providing very consistent opacity. However, tight distributions can be dilatant (shear thickening), causing blockages in high-speed pumping.

- Broad span (High density): A wider curve allows small particles to fit between large ones. This improves packing density, allowing you to have more solids and less water in the glaze, which reduces energy costs during drying.

Key Takeaway: Your choice of distribution width determines both the slurry stability and the final optical opacity.

| Curve Type | Glaze Benefit | Drawback | |

|---|---|---|---|

| Narrow | Consistent Opacity & Gloss | Poor packing; higher water demand. | |

| Broad | High Solids Loading | Risk of uneven melting or surface haze. |

Precise control of these properties eliminates batch-to-batch variation, ensuring that Monday’s glaze behaves exactly like Friday’s glaze.

How Can You Measure Zircon Powder PSD Accurately?

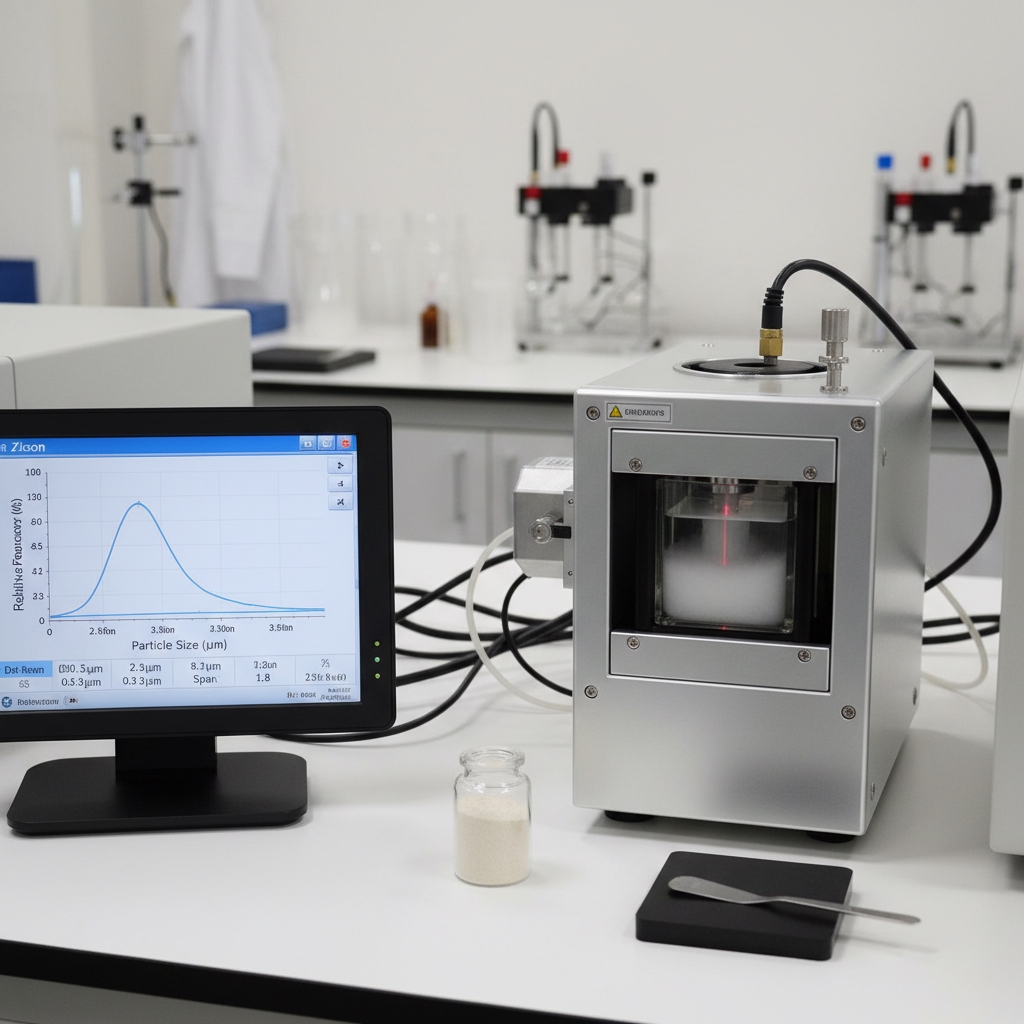

In the past, ceramics manufacturers relied on mesh screens and sedimentation tubes. However, accurate measurement today requires advanced diffraction technology to capture the full nuance of the distribution curve.

How does laser diffraction work?

Laser diffraction is the industry standard for Zircon analysis. It passes a laser beam through a dispersed sample of the powder. The particles scatter the light, and the angle of scattering is inversely proportional to the particle size.

- Speed of analysis: A complete PSD curve is generated in under a minute.

- Repeatability: Unlike sieving, which depends on operator technique, lasers provide objective, repeatable data.

What about sieve analysis limits?

You might be wondering if traditional sieves are enough. The answer is a definitive no. Standard sieves typically bottom out at 45 microns (325 mesh). However, the “rheology-active” fraction of Zircon powder is often between 1 and 10 microns. Sieves completely fail to detect the ultra-fine fraction that controls viscosity, crawling, and drying speeds.

Key Takeaway: Modern laser diffraction is mandatory for detecting the “fines” that alter your viscosity.

| Method | Precision Level | Detection Range | |

|---|---|---|---|

| Laser Diffraction | High (Detects fines) | 0.01 µm – 3000 µm | |

| Wet Sieving | Low (Coarse only) | > 45 µm (Blind to fines) |

Shifting to laser measurement provides the data fidelity needed for modern quality control, allowing you to see the invisible variables affecting your production.

How Do D50 and D90 Metrics Affect Zircon Powder PSD?

When reading a PSD report, you will see D-values. These statistical points represent the median size and the coarse tail of your material’s population, and they serve as critical control points.

What if D50 is too low?

The D50 is the median particle size—half the mass is finer, half is coarser. A very low D50 (e.g., <1.0 µm) means excessive fines. While this creates brilliant whiteness due to high light scattering, it causes the glaze to shrink massively as it dries. This leads to “crawling,” where the glaze cracks and pulls apart before it even enters the kiln. But consider this, if the D50 is too high, you lose opacity, as the particles are too big to effectively scatter light, resulting in a grey or translucent finish.

How does D90 cause settling?

The D90 represents the coarse tail of the distribution (90% of particles are smaller than this size). A high D90 indicates the presence of large, heavy particles. Since Zircon is incredibly dense (Specific Gravity ~4.6), gravity acts aggressively on these coarse particles.

- Hard sediment formation: These particles settle first, interlocking at the bottom of the tank to form a concrete-like layer.

- Clogged spray nozzles: Large particles bridge across nozzle apertures, causing sputtering and downtime.

Key Takeaway: Keeping D90 low prevents sedimentation, while optimizing D50 secures your finish quality.

| Metric | Operational Risk | Target Strategy | |

|---|---|---|---|

| Low D50 | Drying Cracks & Crawling | Maintain >1.0µm for stability. | |

| High D90 | Sedimentation & Clogs | Keep tight to prevent settling. |

Balancing these two metrics is the core of a stable formulation strategy; it is the difference between a suspension that stays mixed and one that separates in an hour.

What Defects Arise from Poor Zircon Powder PSD?

Inconsistent particle sizes are often the root cause of the most expensive surface defects in ceramics. When troubleshooting defects, most operators look at the kiln curve or chemistry, but the physical PSD is often the culprit.

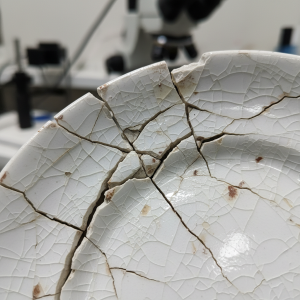

How does crawling start?

Crawling appears as bare islands of clay where the glaze has pulled back. This is purely a physical phenomenon caused by high surface tension and high shrinkage. Excessive ultra-fine particles (sub-micron Zircon) absorb massive amounts of water. As this water evaporates, the glaze layer shrinks significantly. If the bond to the body isn’t strong enough, the glaze cracks and rolls back, leaving bare spots and rolled edges.

What causes pinholes?

It gets worse, as coarse particles trap gas bubbles. Coarse Zircon particles melt later (or not at all) compared to the surrounding glass matrix. This creates a heterogeneous viscosity in the melt. Gas bubbles from the clay body struggle to escape through these “viscous islands” created by coarse Zircon. Often, the bubble bursts right as the cooling cycle begins, freezing a crater (pinhole) into the surface.

Key Takeaway: You can virtually eliminate these defects by strictly auditing incoming raw material PSD.

| Defect | PSD Cause | Mechanism | |

|---|---|---|---|

| Crawling | Excess Fines | High drying shrinkage snaps the glaze film. | |

| Pinholing | Excess Coarse | Trapped gas cannot escape viscous melt areas. | |

| Rough Surface | High D90 | Large particles protrude from the surface. |

Linking defects to PSD data helps you troubleshoot the root cause faster, moving from guesswork to evidence-based resolution.

How Can Mills Optimize Zircon Powder PSD Control?

The milling technology selected by your supplier determines the shape, steepness, and spread of the final particle distribution. Not all “325 mesh” Zircon is created equal.

How does jet milling help?

Jet mills use high-pressure compressed air to accelerate particles into one another. This particle-on-particle impact creates a narrow, steep curve ideal for high-end glazes. Good news is, because there are no grinding media (like alumina balls) involved, this method creates zero contamination. The resulting particles are also more uniform in shape.

What if we blend batches?

Advanced suppliers don’t just grind; they blend. By grinding one batch very fine and another slightly coarser, and then blending them, manufacturers can engineer a “perfect” packing curve.

- Custom viscosity profiles: Tailoring the blend to match the specific rheology of a customer’s spray system.

- Reduced waste: Using the entire range of the material effectively.

Key Takeaway: Advanced milling and blending give you the power to customize Zircon Powder PSD for any application.

| Method | PSD Result | Application | |

|---|---|---|---|

| Jet Mill | Narrow/Steep | High-end sanitary ware; optical glass. | |

| Ball Mill | Broad/Wider | Standard tiles; lower cost glazes. |

Choosing the right milling partner ensures your raw material matches your technical specs and isn’t just a generic commodity.

Why Does Zircon Powder PSD Packing Density Matter?

Packing density defines how tightly particles fit together in the dry state and the slurry state. It influences the raw glaze’s volume, water demand, and the fired glaze’s hardness.

How does void volume change?

Imagine filling a jar with marbles. There is plenty of air (voids) between them. Now, pour sand into the jar; it fills the voids. Now add water. A mix of sizes (optimized PSD) fills void spaces naturally, reducing the amount of medium (water) needed to create a flowable slurry. Think about it, less water means less energy required to evaporate it in the spray dryer or kiln, directly reducing your gas bill.

What if spacing is tight?

Tighter packing creates a harder, more impermeable surface that resists abrasion. In the fired glaze, a high packing density of Zircon ensures a “wall of armor” against cutlery scratches or foot traffic.

- Higher abrasion resistance: Essential for floor tiles.

- Lower shrinkage: Because particles are already touching, they don’t move much during drying/firing.

Key Takeaway: Optimizing for packing density improves both the processing efficiency and the final product durability.

| Density | Process Benefit | Product Benefit | |

|---|---|---|---|

| High | Lower Water Demand | High Scratch Resistance | |

| Low | Easier to Mill | Lower Mechanical Strength |

High packing density is an overlooked factor that drives efficiency in both energy consumption and material performance.

How Does Zircon Powder PSD Impact Production Costs?

Material efficiency and defect reduction are directly tied to the precision of your powder specifications. While premium Zircon with controlled PSD may cost slightly more upfront, the Total Cost of Ownership (TCO) is often lower.

How does waste reduce?

Inconsistent PSD requires operators to constantly adjust the specific gravity, binder levels, and pump pressures of the glaze line. This tweaking results in “start-up scrap” every shift. Consistent PSD eliminates the need for constant line adjustments and “bad batch” disposal. Bottom line is, predictability lowers your cost per unit by stabilizing the process.

What if rework drops?

The “Hidden Factory” is the part of your plant dedicated to fixing mistakes—re-firing pieces, grinding defects, or managing scrap. Fewer surface defects (crawling/pinholes) mean fewer pieces sent back for costly rework.

- Lower labor costs: Less manual inspection and repair needed.

- Material savings: Every scrapped piece is wasted energy, clay, and glaze.

Key Takeaway: Investing in premium, controlled Zircon Powder PSD yields a high ROI through yield improvements.

| Cost Center | PSD Impact | Financial Result | |

|---|---|---|---|

| Rework | Reduced | Increased Plant Capacity | |

| Raw Material | Optimized | Lower Waste/Disposal Costs | |

| Energy | Reduced | Lower Drying/Firing Fuel Usage |

Viewing raw material quality as a cost-saving mechanism changes procurement strategy from “lowest price” to “lowest total cost.”

Which Sectors Rely Most on Zircon Powder PSD?

Different ceramic sectors require vastly different rheological profiles based on their application methods. A glaze that works for a toilet will fail miserably on a floor tile.

How do sanitary wares benefit?

Sanitary ware (toilets, sinks) involves complex vertical surfaces and hidden traps. They require high thixotropy—the glaze must thin out to spray through the gun, but instantly thicken upon hitting the vertical wall to prevent sliding. Surprisingly, minor PSD deviations (too coarse) cause major sagging, where the glaze slides down, leaving the top rim thin and the bottom thick.

What about tile production?

Modern tile production often uses bells, waterfalls, or even inkjet printing.

- Tiles (Leveling speed): Need a smoother flow (lower yield stress) so the glaze levels out instantly into a flat mirror finish before entering the kiln.

- Inkjet Printing: Requires the strictest PSD control (often D99 < 2µm) to prevent blocking the microscopic nozzles of the printheads.

Key Takeaway: You must tailor the Zircon Powder PSD spec to the specific physical demands of your industry vertical.

| Sector | Application Method | Priority Requirement | |

|---|---|---|---|

| Sanitary | Robot Spray | Anti-Sagging / High Thixotropy | |

| Tiles | Bell/Curtain | Rapid Leveling / smoothness | |

| Inkjet | Digital Printhead | Ultra-fine / No coarse particles |

Aligning PSD to your specific manufacturing method is non-negotiable for process capability.

How Does Zircon Powder PSD Stability Affect Storage?

The behavior of the glaze in the tank over time is dictated by the settling velocity of the particles, governed by Stokes’ Law.

How does sedimentation occur?

According to Stokes’ Law, settling speed increases with the square of the particle diameter. This means a particle that is twice as big settles four times faster. Coarse particles settle fastest, creating a hard cake at the bottom that is difficult to redisperse. Don’t forget, when the zircon settles out, the chemistry of the remaining liquid glaze changes, leading to inconsistent opacity if used without re-mixing.

What if hard pan forms?

“Hard panning” is when the sediment cements together. This ruins the entire batch, requiring intense mechanical agitation (which introduces air bubbles) or total disposal. A well-distributed PSD creates a “scaffold” structure where fine particles support the coarse ones, resulting in a soft sediment that is easily stirred back into suspension.

- Shelf life extension: Glazes can be stored for weeks without ruining.

- Ease of mixing: Low shear mixers can restore the suspension.

Key Takeaway: A balanced Zircon Powder PSD ensures your glaze remains homogenous during storage and transport.

| Issue | PSD Cause | Solution | |

|---|---|---|---|

| Hard Pan | Excess Coarse | Reduce D90; add suspension aids. | |

| Separation | Broad Distribution | Tighten span or increase viscosity. |

Stability in the tank translates directly to stability on the line; if you can’t keep it suspended, you can’t apply it consistently.

Conclusion

In the complex world of ceramics manufacturing, inconsistent glaze flow, costly defects, and production downtime are often symptoms of a single root cause: uncontrolled particle size. It is tempting to look for chemical solutions to physical problems, but no amount of binder can fix a fundamentally broken particle distribution. By mastering Zircon Powder PSD, you solve these rheological puzzles at the source, ensuring that your glaze is stable, your application is flawless, and your yields are profitable. Contact us and we offer expert guidance on PSD selection to transform your material science into a competitive advantage. Empowering ceramics innovation through precise material science starts with the right powder.

FAQ Section

Q1: Can I adjust Zircon Powder PSD for better flow?Yes, and it is straightforward. Shifting to a slightly coarser distribution reduces total surface area and viscosity, improving flow rate immediately. However, be careful not to go too coarse, or you will lose suspension stability.

Q2: Does Zircon Powder PSD affect glaze whiteness?Absolutely, and finer is better. Finer particles offer more light-scattering surfaces per gram of material. This significantly boosts opacity and whiteness (L-value), allowing you to potentially use less Zircon to achieve the same coverage.

Q3: Is laser diffraction necessary for PSD testing?Yes, and here is why. Traditional sieves miss the sub-micron fines (<45µm) that drive viscosity changes. Laser diffraction measures the entire range, making it essential for understanding how your glaze will actually behave.

Q4: Can improper PSD cause glaze pinholing?Yes, and it is common. An excess of coarse particles creates localized areas of high viscosity that trap reaction gases. These bubbles burst late in the firing cycle, leaving visible pinholes.

Q5: Does Zircon Powder PSD impact firing temperature?Yes, and it lowers costs. Finer particles have higher surface energy, meaning they react and melt faster. This can potentially allow for lower peak firing temperatures or faster kiln cycles, saving energy.