The quality of ceramic products is significantly impacted by the Coefficient of Thermal Expansion (CTE) mismatch, often referred to as the “silent killer” of ceramics. This issue can lead to failures like crazing and dunting, which compromise the integrity and durability of ceramics. For manufacturers and decision-makers, understanding this challenge is crucial. This article offers practical insights on how to manage CTE using Zircon, an effective additive that enhances product quality and reduces the risk of defects. By mastering this knowledge, you can boost yield and ensure your ceramics meet the highest standards in the industry.

How Does Thermal Expansion Mismatch Impact Ceramics?

The Coefficient of Thermal Expansion (CTE) is a fundamental property crucial for ceramic production. It measures how much a material expands or contracts with temperature changes. When the CTE of the glaze does not match that of the body, it creates internal stresses. This mismatch can lead to significant problems during cooling, where the differences can cause cracks or even total failure of the ceramic piece.

In ceramics, a good CTE fit is essential. If the body expands or contracts differently than the glaze, the final piece can become structurally unsound. For example, when the glaze wants to shrink more than the underlying body, it can create tension. This tension not only leads to surface cracks but can also compromise the piece’s overall integrity, potentially resulting in product recalls or customer dissatisfaction.

Moreover, the implications of an improper CTE fit extend beyond immediate cosmetic issues. They can affect the longevity and usability of the ceramic products, resulting in additional costs associated with replacements, inventory management, and customer service.

Understanding the effects of CTE mismatch helps manufacturers to adjust their formulas or processes to avoid failures. This knowledge is fundamental in producing high-quality ceramics and ensuring customer satisfaction.

| Challenges Due to CTE Mismatch | Solutions |

|---|---|

| Cracks on ceramic surface | Harmonizing CTE values |

| Weak structural integrity | Using suitable additives |

| Costly product rejections | Testing and refining processes |

Through proactive management, manufacturers can significantly mitigate the risks associated with thermal expansion mismatch.

What Are the Consequences of Thermal Expansion Mismatch?

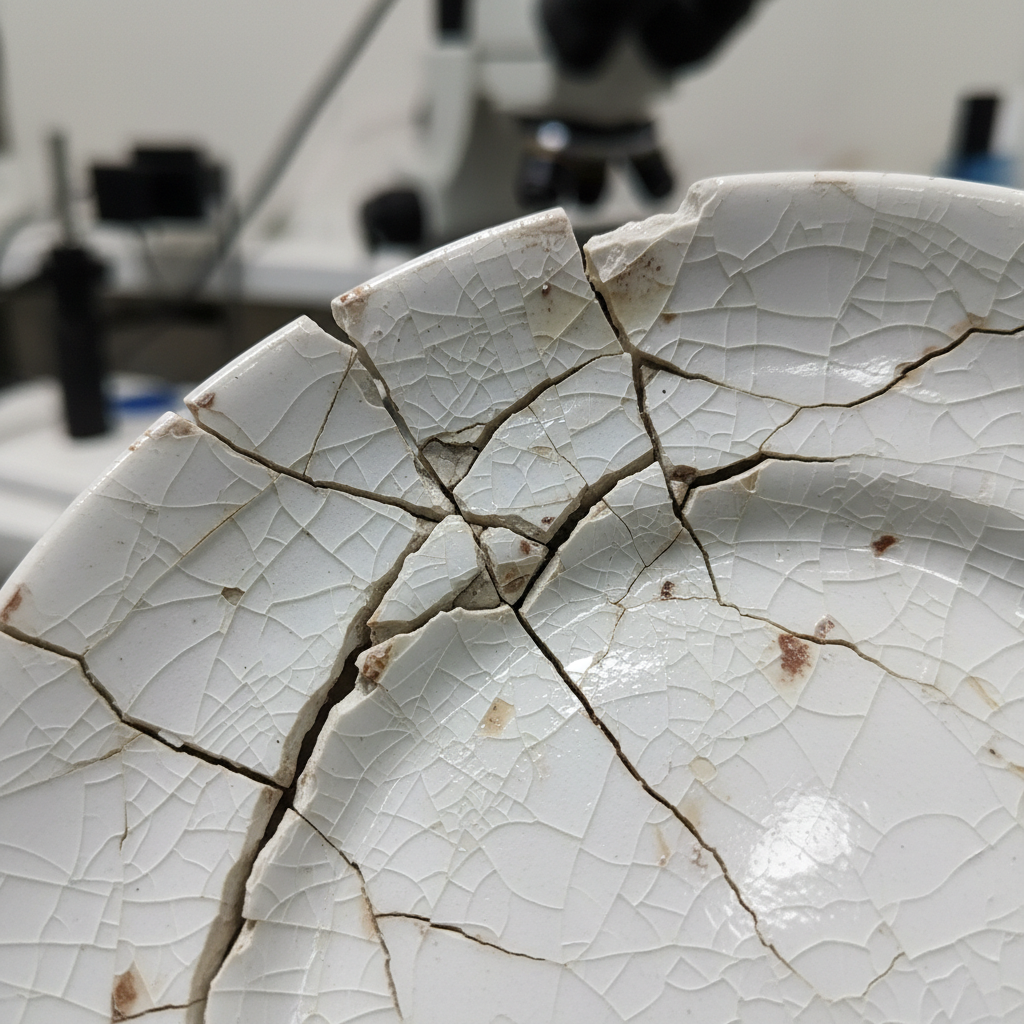

The consequences of thermal expansion mismatch can be serious, leading to mechanical failures in ceramic products. One of the most noticeable issues is crazing, which manifests as a network of fine cracks on the surface. This not only detracts from the visual appeal but can also make the product less durable and functional.

Crazing can occur without any prior visible signs, and once it does appear, it is often too late to rectify it in the manufacturing process, leading to diminished product quality. This type of failure can be particularly damaging in high-performance applications, such as in electrical insulators or high-temperature resistant ceramics, where the integrity of the product is paramount.

Another critical failure mode is dunting. This occurs when the body CTE exceeds the glaze CTE. In such scenarios, the body shrinks more than the glaze, inducing excessive compression that can lead to fractures. These fractures may not be immediately visible, making them particularly insidious and damaging to long-term customer relationships and brand reputation.

Addressing these issues proactively can save time and resources. A well-managed thermal expansion process can prevent many headaches associated with product recalls or replacements. The cost of these failures often extends beyond the financial; they can erode trust with customers and impact a brand’s market position.

| Failure Types | Characteristics |

|---|---|

| Crazing | Surface cracks, aesthetics compromised |

| Dunting | Delayed fractures, structural failures |

Understanding the consequences allows manufacturers to take essential steps in ceramic formulation to enhance product reliability and quality. By integrating robust quality control processes, businesses can preemptively detect and resolve potential issues linked to thermal expansion.

How Can Manufacturers Measure Thermal Expansion?

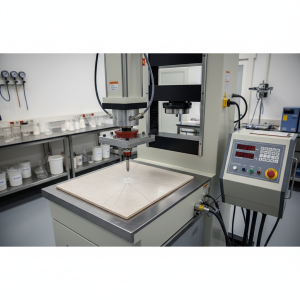

Measuring CTE is vital for ensuring that ceramics are produced correctly. There are several methods to do this, with dilatometry being one of the most common. This technique measures changes in a material’s dimensions as it undergoes temperature changes, providing a clear picture of thermal expansion behavior.

However, ensuring accuracy is critical. Factors like sample preparation, the rate of heating or cooling, and material purity can significantly affect the results. Therefore, manufacturers must follow best practices when measuring CTE. This includes using calibrated equipment and maintaining consistent conditions during testing.

Another effective method for measuring thermal expansion is Thermomechanical Analysis (TMA). This technique uses mechanical stress to observe the deformation of materials as they are subjected to temperature variations. It provides detailed insight into how different materials behave under thermal stress.

Consistent approaches not only improve measurement accuracy but also result in better decision-making regarding material choices and formula adjustments. Regularly revisiting measurement protocols can also lead to continuous improvement in manufacturing processes.

| Measurement Methods | Key Considerations |

|---|---|

| Dilatometry | Equipment calibration, sample purity |

| Optical methods | Specific material characteristics |

| Thermomechanical Analysis | Stress and strain responses |

Through careful measurement, manufacturers can identify and mitigate potential CTE issues before production, leading to higher quality output.

What Strategies Minimize Thermal Expansion Issues?

Effectively managing thermal expansion issues often involves various strategies aimed at harmonizing the CTE of the glaze and the body. One of the most straightforward methods is selecting materials that naturally have compatible CTE values.

Incorporating additives like Zircon can also be beneficial. Zircon, or Zirconium Silicate, has a low CTE, which makes it an excellent choice for modifying glazes. By carefully calculating the amount of Zircon to add to the glaze formula, manufacturers can control the glaze’s expansion to match that of the body, reducing internal stress during firing and cooling.

Moreover, altering the design of ceramic components can help allow for thermal movement. This could involve adjusting the thickness of the glaze or the shape of the piece to accommodate changes in volume during temperature fluctuations.

It’s also important to conduct thorough testing during the development phase to ensure that the chosen materials and formulas yield the desired balance in thermal expansion properties. While this may require additional time and resources initially, it ultimately leads to fewer product failures down the line.

| Strategies | Implementation Steps |

|---|---|

| Material selection | Identify compatible CTEs |

| Additive integration | Calculate optimal Zircon amounts |

| Design adjustments | Alter shapes/thickness |

These strategies, when applied successfully, can lead to a notable reduction in product failures and increased customer satisfaction. Furthermore, ongoing monitoring and adjustments can help maintain the effectiveness of these strategies over time.

How Do Industries Address Thermal Expansion Challenges?

Industries have implemented various strategies to manage thermal expansion challenges effectively. For example, ceramics used in the aerospace industry require stringent quality standards. Here, the selection of materials that exhibit minimal CTE mismatch is critical for safety and performance.

Moreover, many manufacturers utilize advanced computer modeling to simulate thermal expansion behavior. This helps identify potential issues early in the design process, enabling adjustments before the prototyping stage. These modeling systems allow for virtual testing of different materials and designs, providing insights that can lead to more informed material selections.

Case studies indicate that companies investing in research and product development see long-term benefits. For instance, a porcelain manufacturer that systematically optimized its CTE fit saw a reduction in product defects by over 20% in just one year. This case illustrates how critical attention to CTE can significantly enhance overall product quality and consumer trust.

| Industry Examples | CTE Management Techniques |

|---|---|

| Aerospace | Materials selection, modeling |

| Pottery and Tile | Testing and refinement |

| Electrical Insulators | Advanced simulations |

Learning from these strategies can be invaluable for companies looking to enhance their ceramic products’ quality and reliability. By adopting an organizational culture centered on quality and continuous improvement, businesses can better navigate the complexities of ceramic production.

What Should Buyers Consider Regarding Ceramics and CTE?

For buyers, understanding the implications of thermal expansion is crucial when selecting ceramic suppliers. Looking for information on a supplier’s approach to managing CTE is a good starting point.

Buyers should focus on asking specific questions to gauge a supplier’s commitment to product quality and consistency, such as:

- What materials do you use to ensure a proper CTE fit?

- How do you measure and test for thermal expansion in your products?

- What practices do you have in place to prevent issues like crazing and dunting?

These questions can provide crucial insights into the vendor’s commitment to quality assurance and their understanding of key ceramic production issues.

Furthermore, quality assurance protocols are essential. Suppliers should have established processes for measuring and maintaining the quality of their products, ensuring they meet industry standards. Certifications from recognized organizations can also provide additional confidence in a supplier’s capabilities.

| Buyer Considerations | Key Questions |

|---|---|

| Supplier selection | CTE fit practices, testing methods |

| Quality assurance | Protocols for measurement and validation |

Understanding these factors can lead to more informed decisions, ensuring you partner with suppliers that prioritize quality. This partnership is vital in achieving your objectives and enhancing your product offerings in the competitive ceramics market.

How Can Continuous Improvement Enhance Ceramic Quality?

Continuous improvement is a fundamental principle in ceramic manufacturing, and it involves regularly assessing and refining processes to enhance product quality. This starts with a commitment to research and development to explore new materials, techniques, and technologies that could improve ceramic performance.

Gathering feedback from customers also plays a critical role in this process. Understanding the real-world performance and potential issues can provide insights for further adjustments. For instance, if a specific type of glaze frequently fails in the field, it may indicate the need to refine the CTE measurement or formulation.

Furthermore, adopting best practices set by industry standards organizations can guide continuous improvement efforts. Standards like those from ASTM International or ISO provide benchmarks for quality and performance that manufacturers can strive to meet or exceed.

| Continuous Improvement Strategies | Implementation Steps |

|---|---|

| R&D | Explore new materials/techniques |

| Customer feedback | Gather insights for product adjustments |

| Industry standards | Adopt benchmarks for quality |

These strategies facilitate ongoing enhancements in ceramic quality and reliability, ultimately benefiting both the manufacturer and end-users. As companies commit to continuous improvement, they can better anticipate market trends and customer needs, solidifying their position as leaders in the ceramics industry.

Conclusion – Mastering CTE is Mastering Your Yield

In summary, understanding the role of thermal expansion mismatch in ceramic quality is vital for manufacturers. By effectively leveraging Zircon and ensuring a good CTE fit, you can significantly reduce product failures. This leads to higher yield and profitability for your operations. At Global Industry, we are committed to supporting your journey toward improved ceramic quality. For specialized assistance and resources, feel free to reach out to us and enhance your production capabilities.

FAQ Section

Q1: What is thermal expansion mismatch in ceramics?

Thermal expansion mismatch refers to the difference in how two materials expand when subjected to temperature changes, which can lead to stress and potential failures in ceramic products.

Q2: How can I measure the thermal expansion of ceramics?

You can measure thermal expansion using techniques such as dilatometry, which assesses dimensional changes of materials as they are heated or cooled.

Q3: What are common problems caused by thermal expansion mismatch?

Common problems include cracking, warping, and reduced thermal shock resistance, which can compromise the integrity of ceramic products.

Q4: How do manufacturers minimize thermal expansion issues?

Manufacturers can minimize issues by selecting materials with similar CTEs, designing products to accommodate thermal movement, and employing innovative manufacturing techniques.

Q5: Why is understanding CTE important for ceramic buyers?

Understanding CTE helps buyers select ceramics that meet performance standards and ensures product longevity, reducing the risk of failures in critical applications.