Trusted & Proven Zirconium Silicate Powder Supplier from China

- Offering high-purity zirconium silicate powder (ZrSiO₄) in 64–65% ZrO₂ grades with D50 around 0.95 µm.

- Designed for ceramic glazes, coatings, and refractories requiring excellent whiteness, strong opacity, and thermal stability.

- eliable bulk supply, consistent quality, and customizable particle sizes to meet different industrial needs.

What is Zirconium Silicate Powder?

Zirconium silicate powder is a high-performance inorganic material derived from natural zircon sand through high-temperature calcination, precision grinding, and classification processes. Combining excellent chemical stability, high-temperature resistance (melting point >2500°C), and high refractive index, it serves as a versatile material widely adopted across industrial applications.

Advantages

- Cost-Effective Performance: 35–50% cost reduction compared to zirconia powder, ideal for large-scale industrial use.

- Process Compatibility: Custom surface treatments (e.g., silane coating) to optimize bonding with resin/metal matrices.

- Global Supply: Samples (from 1kg) to bulk orders (100+ tons), backed by technical reports and application guidance.

Why Choose Our Zirconium Silicate Powder?

Our zirconium silicate powder is engineered to meet the demanding standards of ceramic and refractory industries worldwide. Here are the key benefits our clients rely on:

| Advantage | Details & Industrial Impact |

|---|---|

| High Zirconia Content (≥65%) | Ensures excellent chemical stability and thermal resistance in high-temperature environments such as kilns, furnaces, and glaze firing lines. |

| Consistent Fine Particle Size (D50: 1.5–2.5 μm) | Allows for uniform dispersion in glaze suspensions, enhancing surface smoothness and opacity without causing sedimentation or pinholes. |

| Excellent Opacifying Effect | Delivers a strong whitening and masking effect in ceramic glazes and sanitaryware, improving visual appeal and hiding base defects. |

| Low Iron and Impurities | Fe₂O₃ content below 0.08% prevents discoloration and helps maintain brightness in finished ceramic or tile surfaces. |

| High Refractoriness | Withstands prolonged exposure to temperatures above 1600°C, ideal for refractory castables, kiln furniture, and insulation products. |

| Stable Chemical Structure | Inert ZrSiO₄ resists corrosion from alkalis, acids, and molten glass, extending equipment lifespan and reducing maintenance cost. |

| Enhanced Mechanical Strength | Improves impact resistance and reduces cracking during drying or firing stages in ceramic production. |

| Good Compatibility | Works well with feldspar, kaolin, alumina, and frits, minimizing reaction issues in complex glaze systems. |

| Custom Grades Available | Micronized or milled to customer specs, including ultra-fine grades (< 1 μm) to support different application needs. |

| Environmentally Compliant | Free of hazardous substances and RoHS compliant, supporting clean and sustainable manufacturing practices. |

Competitive Zirconium Silicate Powder Price

Which Industries Benefit Most from Our Zirconium Silicate Powder?

Zirconium silicate powder serves as a high-performance opacifier and structural filler in a wide range of industrial applications. In the ceramic industry, it is commonly used in floor tiles, porcelain slabs, sanitaryware, household tableware, rustic pottery, and special porcelain to enhance glaze opacity, whiteness, and firing stability. It also plays a key role in the formulation of plastic compounds—especially epoxy, silicone, and ethylene resins—where it improves thermal resistance and dielectric strength. For refractories, it supports high-temperature performance in castables, kiln components, furnace linings, and refractory cement, delivering consistent durability under extreme conditions.

Ceramic Industry

Ceramic Glazes: Zirconium silicate powder is the most important opacifier and whitening agent in ceramic glazes. Due to its high refractive index and good chemical stability, it can impart excellent whiteness, gloss, and opacity to the glaze surface, while also improving the hardness and wear resistance of the glaze. Zirconium silicate powders of different particle sizes can be used to produce matte, semi-matte, or glossy glazes.

Ceramic Bodies: In certain special ceramic bodies, zirconium silicate powder can also be used as an additive to improve the sintering performance, mechanical strength, and thermal shock stability of the body.

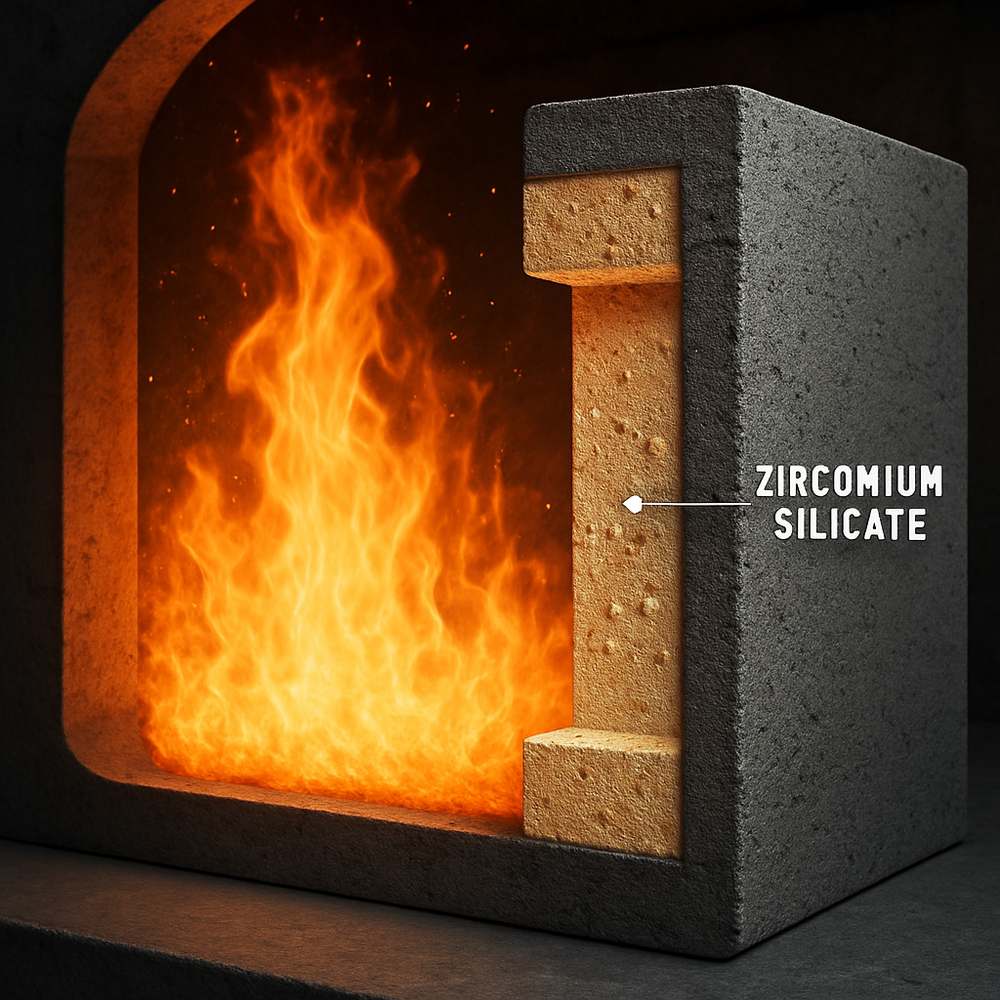

Refractory Materials

Refractory Bricks and Castables: Used in the production of refractory bricks and castables for high-temperature equipment such as glass melting furnaces, steel industrial furnace linings, and non-ferrous metal smelting furnaces, significantly extending the service life of furnace linings and improving corrosion resistance.

High-Temperature Coatings: As a component of high-temperature coatings, used to protect metal or ceramic surfaces from high-temperature oxidation and corrosion.

Plastics Industry

Epoxy Resin Formulations and Sealant Resins: Zirconium silicate powder can be added as a filler to epoxy resin formulations and sealant resins to enhance their strength, hardness, wear resistance, corrosion resistance, and dimensional stability.

Silicones and Vinyl Resins: In silicones and vinyl resins, zirconium silicate powder can also be used as a filler to improve the physical and mechanical properties of the materials, such as increasing hardness, wear resistance, and potentially enhancing flame retardancy.

General Resin Fillers: Due to its high refractive index, good chemical stability, and wear resistance, zirconium silicate powder is widely used as a filler in various resins. It can improve the fluidity and gloss of products, and reduce costs.

Paints and Inks

White Pigment and Filler: As an efficient white pigment and filler, it can improve the hiding power, whiteness, and weather resistance of paints and inks.

Functional Coatings: In certain functional coatings, such as wear-resistant coatings and anti-corrosion coatings, zirconium silicate powder can be used as an enhancing component to improve the hardness and durability of the coating.

Other Emerging Applications

Biomedical Materials: In the field of bioceramics and biocompatible coatings, zirconium silicate has good biocompatibility and can be used to manufacture dental materials, bone repair materials, etc.

Catalyst Carriers: As an inert carrier, it can be used to load active components and play a role in certain catalytic reactions.

Get Custom Solution

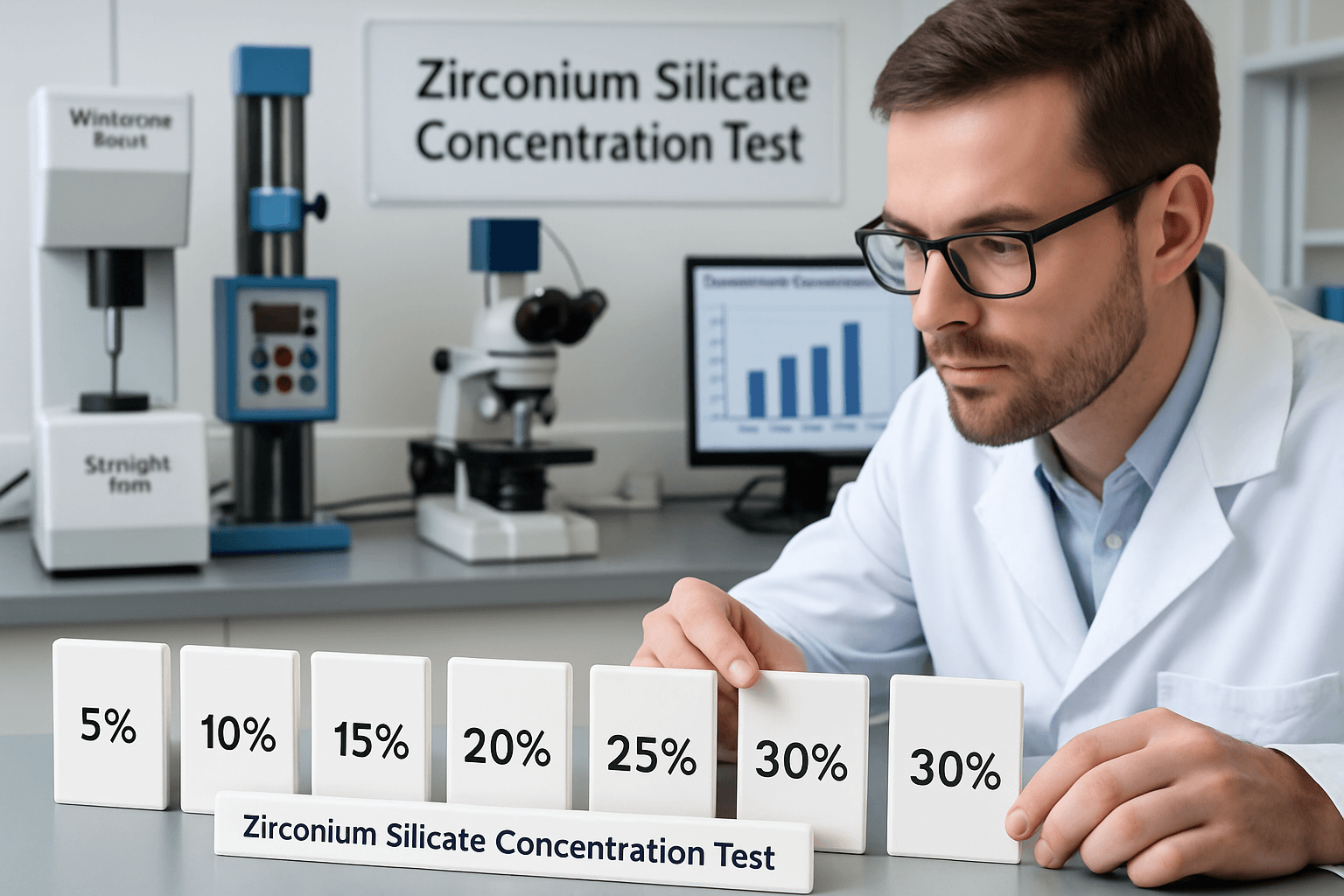

Standard Grades of Zirconium Silicate Powder – Regular Supply & Customizable Options

We offer a full range of zirconium silicate powder grades with ZrO₂ content from ≥25% to ≥65%, meeting the varied performance and budget requirements of ceramic and industrial clients. All grades are characterized by offwhite appearance, high chemical stability, and controlled particle size distribution, with D50 values ranging from 0.90 to 1.20 μm and Fe₂O₃ content as low as <0.10%. Particle sizes and impurity levels are tightly controlled, and custom formulations can be developed upon request. Each product is packed in 40kg composite paper bags and manufactured under strict quality control to ensure consistency in large-scale production environments.

Zirconium Silicate Powder Technical Specifications

| Formula | Properties | Packing |

|---|---|---|

| ZrSiO₄ | Offwhite powder, high chemical stability | Composite paper bags in 25/40 kgs |

| Product | ZrO₂ | D50 (μm) | D90 (μm) | Fe₂O₃ | TiO₂ |

|---|---|---|---|---|---|

| 65 Zirconium silicate | ≥65% | 0.950 | 1.6–1.7 | <0.10 | <0.15 |

| 64 Zirconium silicate | ≥64% | 0.978 | 1.6–1.7 | <0.10 | <0.15 |

| 60 Zirconium silicate | ≥60% | 0.913 | 1.6–1.7 | <0.15 | <0.15 |

| 55 Zirconium silicate | ≥55% | 0.900 | 1.6–1.7 | <0.20 | <0.15 |

| 46 Zirconium silicate | ≥46% | 0.900 | 1.6–1.7 | <0.20 | <0.15 |

| 40 Zirconium silicate | ≥40% | 0.900 | 1.6–1.7 | <0.20 | <0.15 |

| 33 Zirconium silicate | ≥33% | 0.900 | 1.6–1.7 | <0.20 | <0.15 |

| 25 Zirconium silicate (embryo) | ≥25% | 1.200 | 1.6–1.7 | <0.30 | <0.15 |

Note: Specifcafions can be customized to customer’s requirements.

What Makes Global Industry a Reliable Partner in Zirconium Materials?

GLOBAL INDUSTRY specializes in the research, production, and sales of zirconium materials.

Our main products include zirconium oxide powder (zirconia), zirconium silicate powder, zircon powder, zircon sand, and ceramic structural parts such as zirconia beads, zirconium silicate beads, and zircon–aluminum composite beads — covering over 40 specifications.

With reliable quality and stable supply, our zirconium products are widely used in ceramics, coatings, and industrial applications, earning strong recognition from domestic and international customers.

Relying on a complete zirconium supply chain and continuous technological innovation, we have become a leading zirconium materials manufacturer in China, committed to providing high-quality, consistent, and cost-effective zircon products for global partners

Our Team: We have a leading R&D, production and after-sales service team, constantly improves and perfects the production line, optimizes the production process, and builds a series of complete industry industrial chains from R&D, production, quality inspection, channels, services, etc. The company currently has more than 100 employees.

Our Strength: Global Industry is a national high-tech enterprise and a key strategic new industry in Shandong Province, focusing on the research, development, and manufacturing of zirconium materials.

Recognized as one of China’s top zirconium material brands, the company has received multiple honors, including the Top Ten Casting Material Brand, China Coating Raw Materials Award, and the Gold Award for Zirconium Industry Science and Technology.

Driven by technological innovation, we have established long-term cooperation with global and domestic research institutions such as the Shanghai Institute of Silicon (Chinese Academy of Sciences), China University of Geosciences, Tsinghua University, and Shandong University of Science and Technology. Through these partnerships, we have built a national-level R&D and production center for zirconium silicate, nano-composite zirconium oxide powder, and zirconia grinding media, making us one of the largest zirconium material production bases in China.

Precision-Engineered Zirconium Silicate: Purity You Can Trust

At Global Industry, we understand that in the demanding world of industrial manufacturing, the purity of raw materials is not just a preference—it's a critical requirement. Our Zirconium Silicate is meticulously processed to achieve an unrivaled level of purity, ensuring consistent performance and superior end-product quality for our B2B partners. We leverage advanced beneficiation techniques and stringent quality control protocols throughout our production cycle, from raw ore sourcing to final product packaging. This commitment to purity directly translates into enhanced material properties for your applications, reducing defects, optimizing processes, and ultimately safeguarding your investment. Whether for advanced ceramics, precision casting, or specialized refractories, our Zirconium Silicate provides the foundational integrity your operations demand, minimizing impurities that could compromise performance and maximizing the efficiency of your production lines. Choose Global Industry for Zirconium Silicate that sets the benchmark for industrial purity and reliability.

Advanced Manufacturing Capabilities: Your Strategic Supply Partner

As a leading factory in China, Global Industry boasts state-of-the-art manufacturing facilities specifically designed for the high-volume production of Zirconium Silicate. Our advanced production lines incorporate cutting-edge technology and automated processes, guaranteeing not only consistent product quality but also the capacity to meet the most demanding supply requirements of our global B2B clientele. We understand the critical importance of a reliable supply chain in maintaining your production schedules and minimizing downtime. Our robust infrastructure, coupled with efficient logistics and a dedicated team, ensures timely delivery and seamless integration into your operations. By partnering with Global Industry, you gain a strategic supplier capable of providing the scale, consistency, and reliability essential for your long-term success. Our commitment to continuous improvement in manufacturing processes means you benefit from the latest advancements in material production, ensuring a competitive edge in your respective markets.

Tailored Solutions and Technical Expertise: Beyond Just a Supplier

At Global Industry, we believe in fostering true partnerships with our clients, extending beyond mere transactional relationships. Our team of experienced material scientists and technical experts is dedicated to providing tailored solutions and comprehensive support for your specific application needs. We understand that each industry and even each client may have unique requirements for Zirconium Silicate. Whether you need specific particle size distributions, customized chemical compositions, or advice on optimizing material integration into your processes, our technical team is ready to collaborate. We offer in-depth technical consultations, material analysis, and R&D support to help you achieve optimal performance and overcome complex challenges. This commitment to collaborative innovation ensures that you not only receive a high-quality product but also gain a valuable resource in material science, helping you drive efficiency, reduce costs, and develop cutting-edge products.

Global Reach and Reliable Logistics: Your Seamless Supply Chain Solution

With Global Industry, geographical distance is no barrier to accessing premium Zirconium Silicate. As a factory based in China, we have established a robust global logistics network and extensive experience in international trade, ensuring efficient and reliable delivery of our products to clients worldwide. We manage the complexities of export documentation, customs procedures, and international shipping, providing a seamless supply chain solution from our factory floor directly to your production facility. Our commitment to timely and secure delivery minimizes your logistical concerns and allows you to focus on your core business. We offer flexible packaging and shipping options to accommodate diverse client needs, ensuring that your Zirconium Silicate arrives in optimal condition, ready for immediate use. Partner with Global Industry for a truly global reach and a supply chain solution that prioritizes your operational continuity and peace of mind.

Production Workshop and Quality Control

FAQ

We are a factory with our own production line and QC team in China.

Our MOQ starts from 100 kg. Trial orders and pilot runs are welcome.

Absolutely. Every shipment includes full documentation. Additional test reports can be provided upon request.

Typically 7–14 days for standard products. Custom specs may take slightly longer.

Yes. We support custom purity, particle size, and even composite blends tailored to your application.

Global Industry is a trusted supplier of zircon materials, including zircon sand, zircon powder, zirconium silicate, and zirconia. We serve global ceramics, refractories, and advanced industries with stable quality and reliable export service

- Tel: +86-13708962673 |+86-13371335587 |+86-18561865879

- WhatsApp: +86-13708962673 |+86-13371335587 |+86-18561865879

- Email: aileen@qglobalindustry.com, lynx@qglobalindustry.com

- www.qglobalindustry.com